Composite fireproof door

A technology for fire doors and door frames, applied in fire doors, sealing devices, etc., can solve problems such as affecting fire protection effect, wasting wood, and wasting wood resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

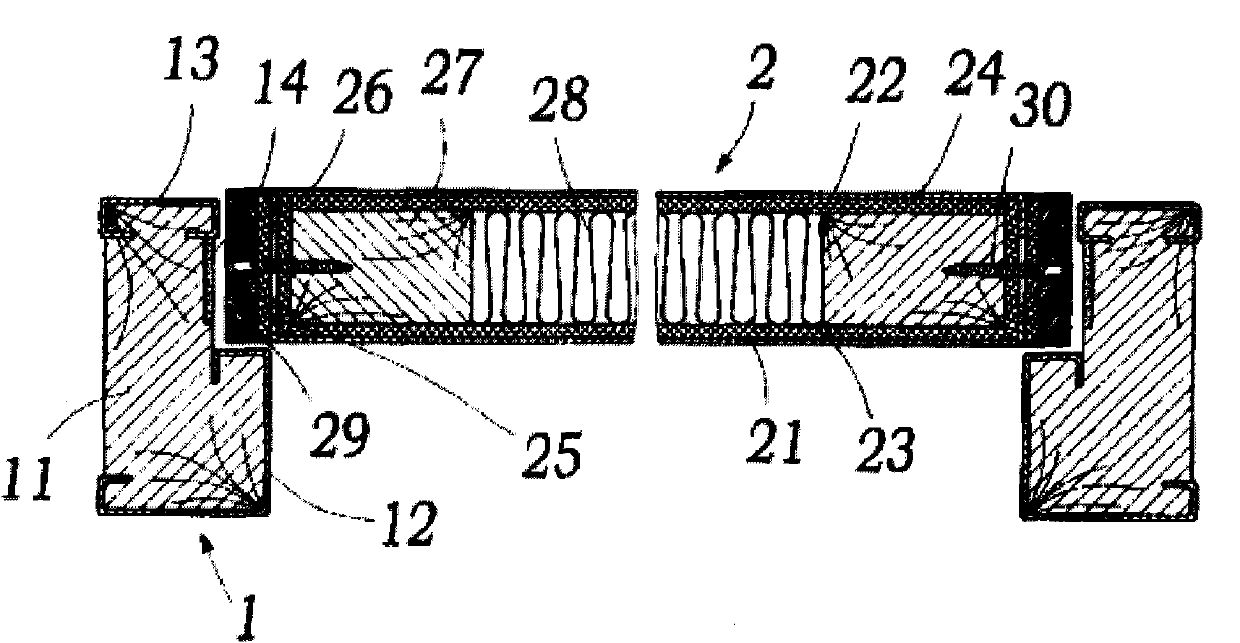

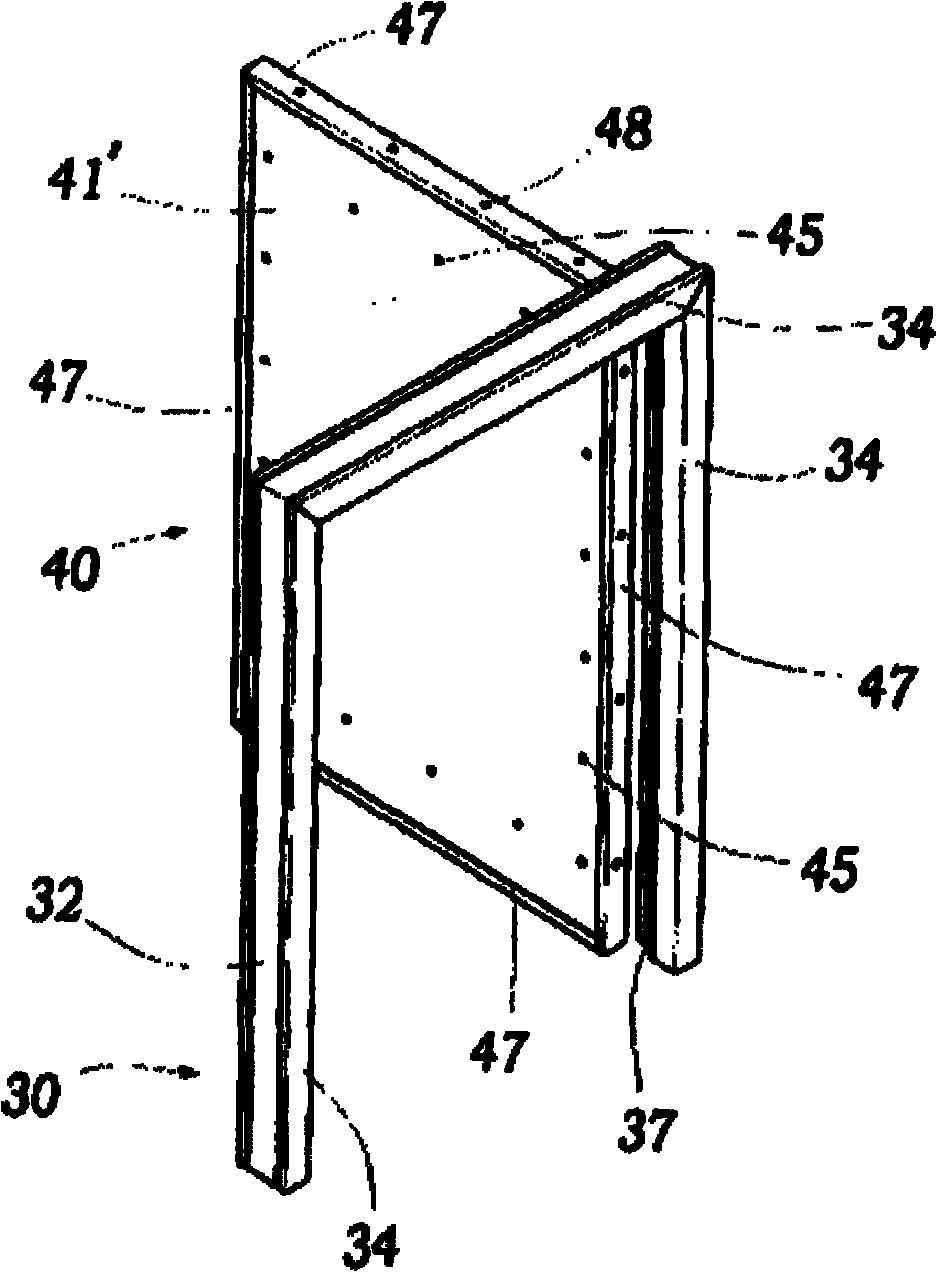

[0016] Please refer to the Figure 2 to Figure 5 , The composite fire door structure of the present invention mainly includes a composite fire door frame 30 and a composite fire door 40, and the composite fire door 40 is fixed on the composite fire door frame 30 by hinges.

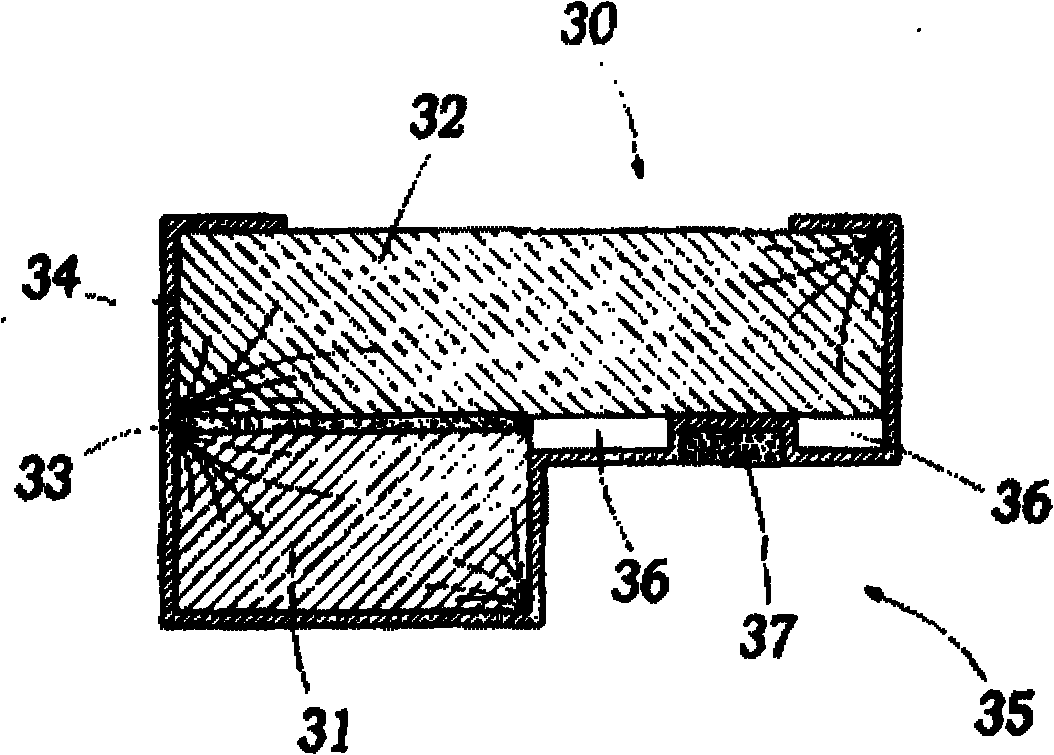

[0017] The composite fireproof door frame 30 is composed of left, right and upper frames. The frame system is composed of two solid wood angles (132) with equal thickness and different widths. image 3 The L-shaped door frame 30 is shown.

[0018] Composite fire door 40 has front and back two steel plates 4141 ', between two steel plates 4141 ', the fixed fire prevention plate is sandwiched. The fire-proof board is constructed with a plywood 4242' on the inner surface of the two steel plates 4141', the plywood 4242' is an ordinary wood plywood, and a fireproof board 4343' is arranged on the inner surface of the two plywood 4242', and the fireproof board 4343' is magnesium oxide board or calcium silicate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com