Oil decoloring device

An equipment and oil technology, applied in the field of oil purification equipment, can solve the problems of large oil loss, harsh conditions, difficult to popularize, etc., and achieve the effects of high production efficiency, simple operation and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

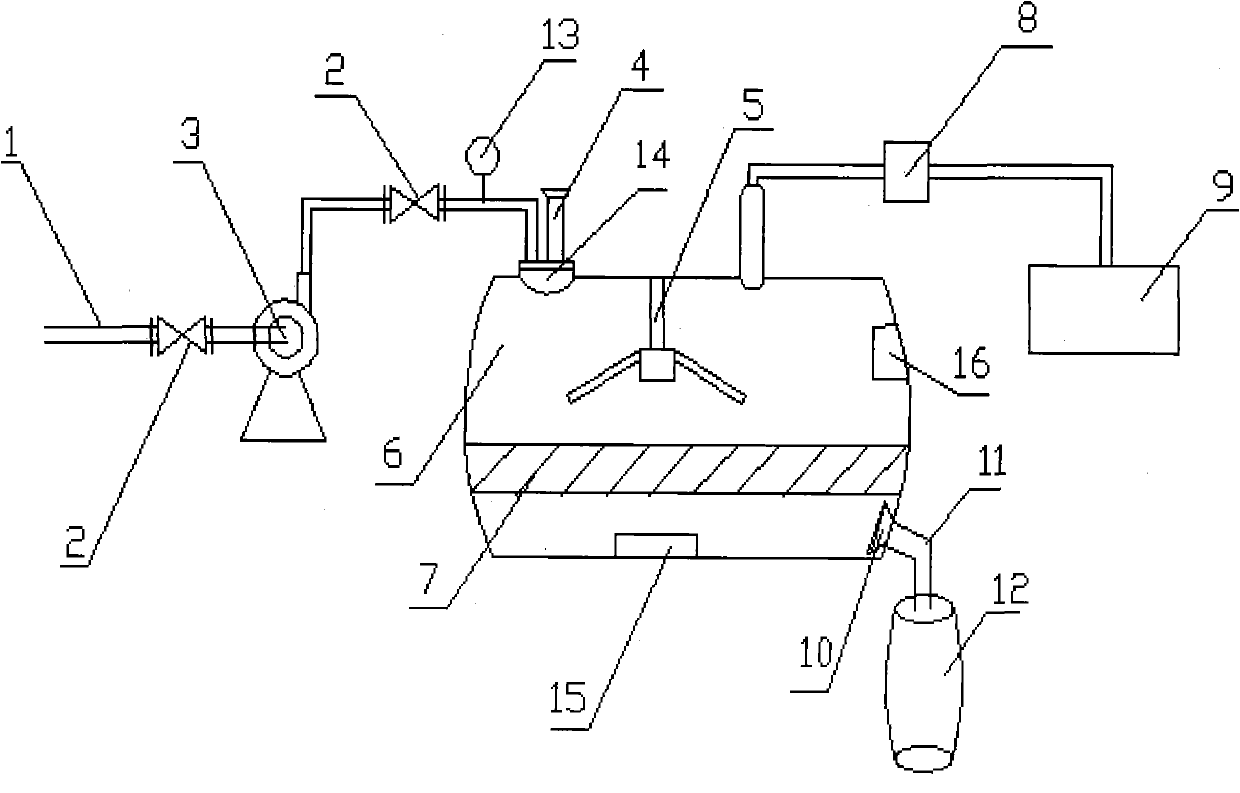

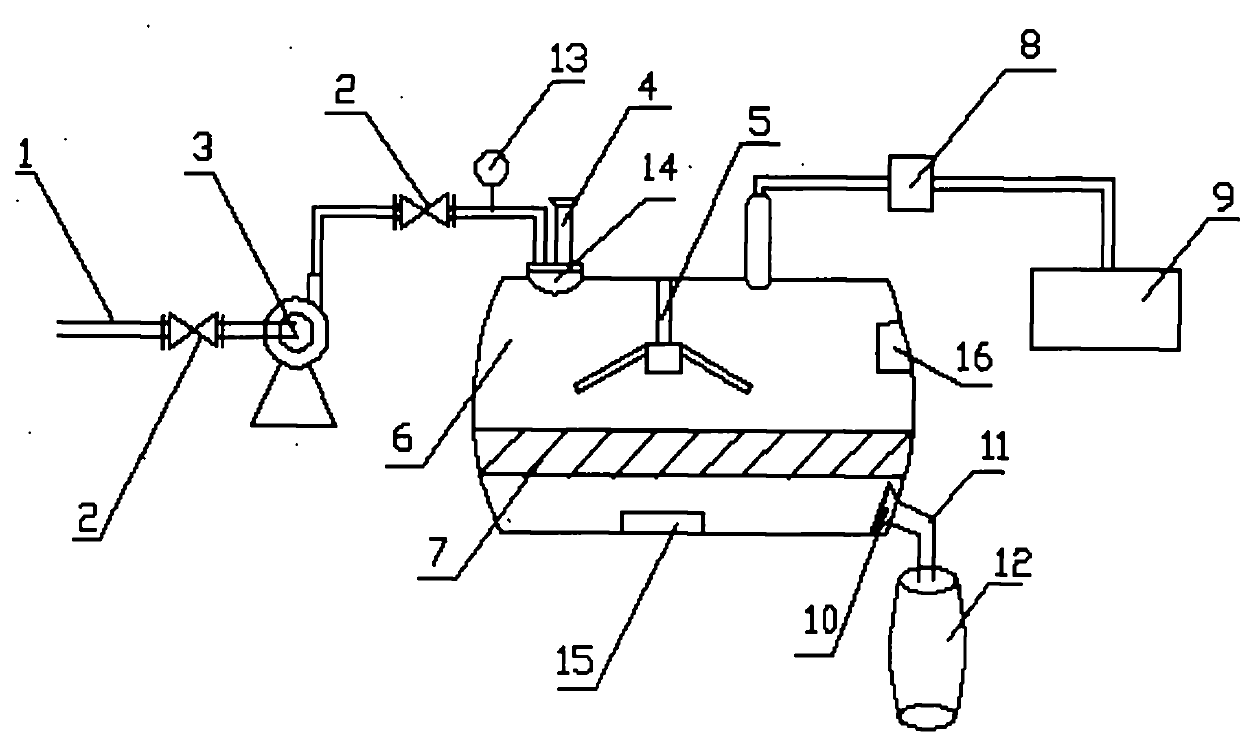

[0012] In order to clearly illustrate the technical characteristics of this solution, the present invention will be further described below according to the drawings and specific implementation methods.

[0013] Oil product decolorization equipment of the present invention is as shown in Figure 1, and this oil product decolorization equipment mainly comprises oil inlet pipeline 1, oil outlet pipeline 11, decolorization kettle 6, and the inlet and outlet of described decolorization kettle 6 are respectively connected with oil inlet pipeline 1 and The oil outlet pipeline 11 is connected in series, and it is characterized in that there is a filter 10 at the outlet of the decolorization kettle 6, a decolorizer 7 is arranged in the decolorization kettle 6, and a condenser 8 and a tail gas collection tank 9 are connected in series through the pipeline in the decolorization kettle 6, during the decolorization process The exhaust gas produced in the process can be condensed by a conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com