Industrialized production method of high-purity pemetrexed disodium

A technology of pemetrexed disodium and its production method, which is applied in the field of medicinal chemistry, can solve the problems of a large number of solvents and heating dissolution, low solubility, product damage, etc., and achieve easy industrial scale-up production, simple and easy operation, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of crude pemetrexed disodium

[0028] The crude pemetrexed disodium can be prepared by referring to the "Journal of Zhongwei Pharmaceutical Industry" 2005.36(12), 727-729 and other documents or the following methods.

[0029] (a) N-4-[2-(2-Amino-4-oxo-4,7-dihydro-1H-pyrrolo[2,3-d]pyrimidin-5-yl)ethyl]benzoyl- Preparation of L-glutamic acid diethyl p-toluenesulfonate (intermediate)

[0030] Add 4-[2-(2-amino-4-oxo-4,7-dihydro-1H-pyrrolo[2,3-d]pyrimidine-5- obtained according to the preparation method of Example 1 into the reaction flask (Yl)ethyl]benzoic acid 24.8g (0.08mol), DMF175ml, N-methylmorpholine 25g (0.2mol) stirred, and then added 2-chloro-4,6-dimethoxy-1,3,5- Triazine (CDMT) 18.9g0.035mol), react at room temperature for 2h. Add 25.7 g (0.1 mol) of L-glutamate diethyl hydrochloride, and react at room temperature for 4 hours. After the reaction was completed, the reaction solution was slowly added to 500 ml of 5% sodium bicarbonate solution, a...

Embodiment 2

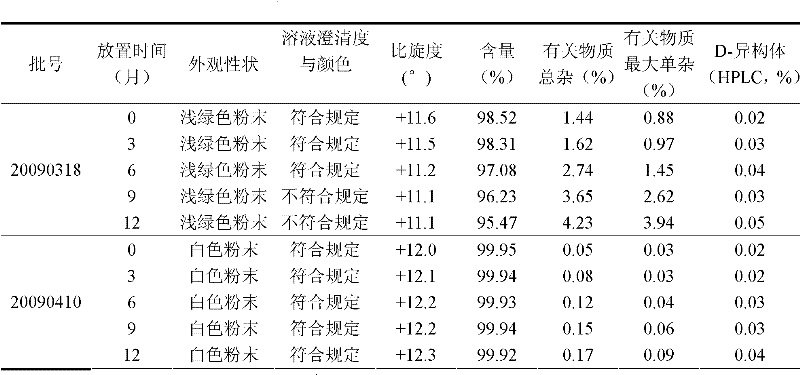

[0034] Example 2 Preparation of high-purity pemetrexed disodium

[0035] In this embodiment, the preparation method of high-purity pemetrexed disodium includes the following steps:

[0036] 1) Add 5g crude pemetrexed disodium (light green, maximum single impurities: 0.88%) to the reaction flask, add 25g (ie 25ml) of water at room temperature (21°C) and stir to dissolve the solid;

[0037] 2) Add 125ml of tetrahydrofuran to the reaction solution in step 1), then add 0.5g of 300 mesh diatomaceous earth, and stir for 20 minutes;

[0038] 3) Filter the reaction solution of step 2), add the filtrate to another reaction flask, add 250ml of tetrahydrofuran, crystallize at room temperature (21°C) for 6 hours; filter, put the solid obtained in a vacuum drying oven to dry, at 35°C Dry under reduced pressure for 4 hours to obtain 4.3 g of white product, yield: 86%. HPLC detection purity: 99.96%, maximum single impurities 0.03%, HPLC detection conditions are the same as in Example 1.

Embodiment 3

[0039] Example 3 Preparation of high-purity pemetrexed disodium

[0040] In this embodiment, the preparation method of high-purity pemetrexed disodium includes the following steps:

[0041] 1) Add 505g of crude pemetrexed disodium to a 20L glass reactor (light green, maximum single impurities: 1.45%, total impurities 3.09%), add 7500g of water (ie 7500ml) at a temperature of 15℃ and stir to make a solid Dissolve

[0042] 2) Add 7500ml of tetrahydrofuran to the reaction solution of step 1), then add 20g of 600 mesh diatomaceous earth, and stir for 5min;

[0043] 3) Filter the reaction liquid of step 2), add the filtrate to a 50L reaction kettle, add 37.5L of tetrahydrofuran, and crystallize at 10°C for 10 hours; filter, put the solid obtained in a vacuum drying oven to dry, and reduce pressure at 30°C After drying for 6 hours, 447 g of a white product was obtained, with a yield of 88.5%. The purity detected by HPLC is: 99.94%, the maximum single impurity is 0.04%, and the detection c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com