Light guide body covered with optical membrane

A technology of an optical film layer and a light guide body is applied in the field of light guide bodies, and can solve the problems of high cost, limited application surface of the light guide plate, complicated manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

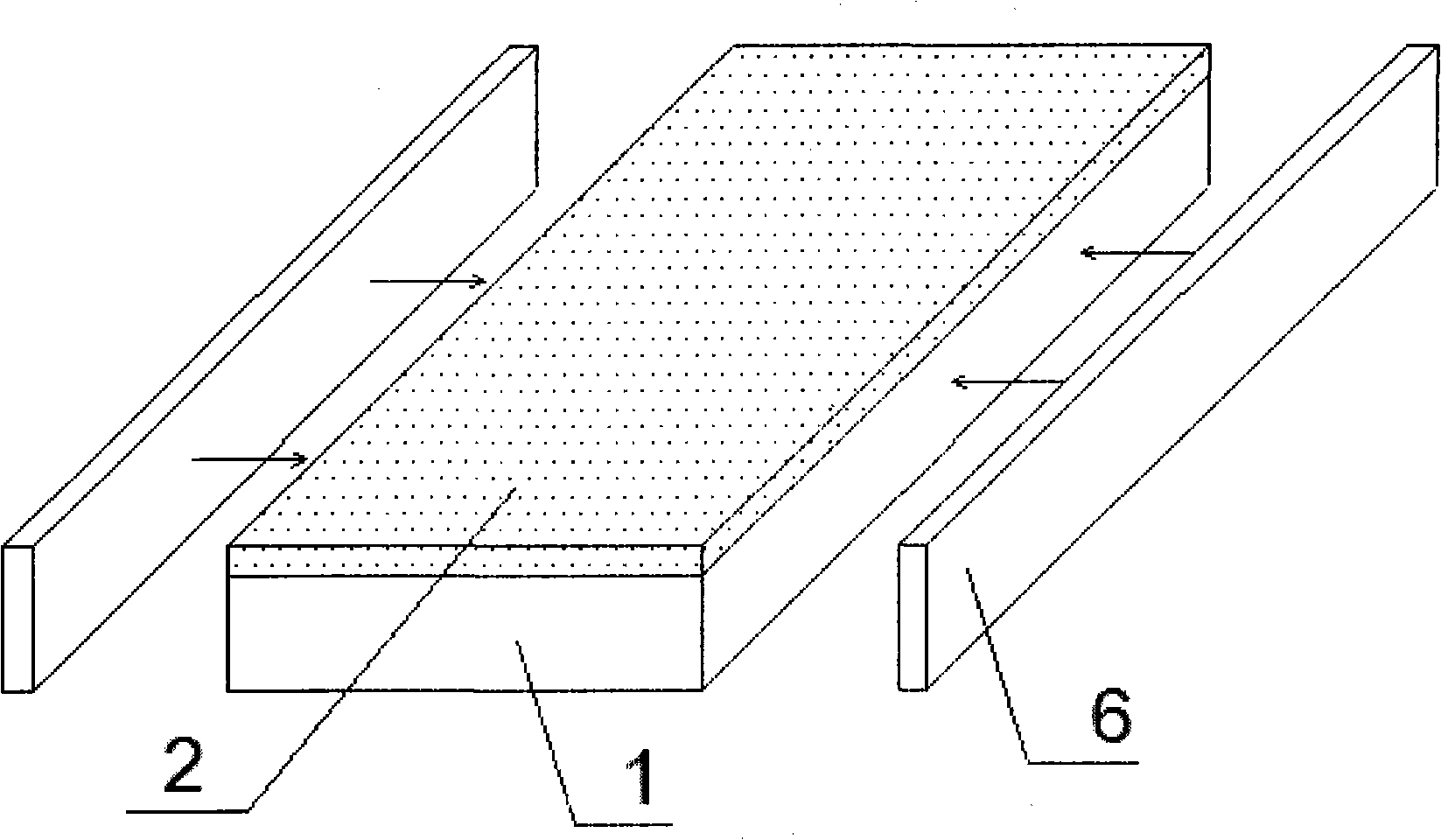

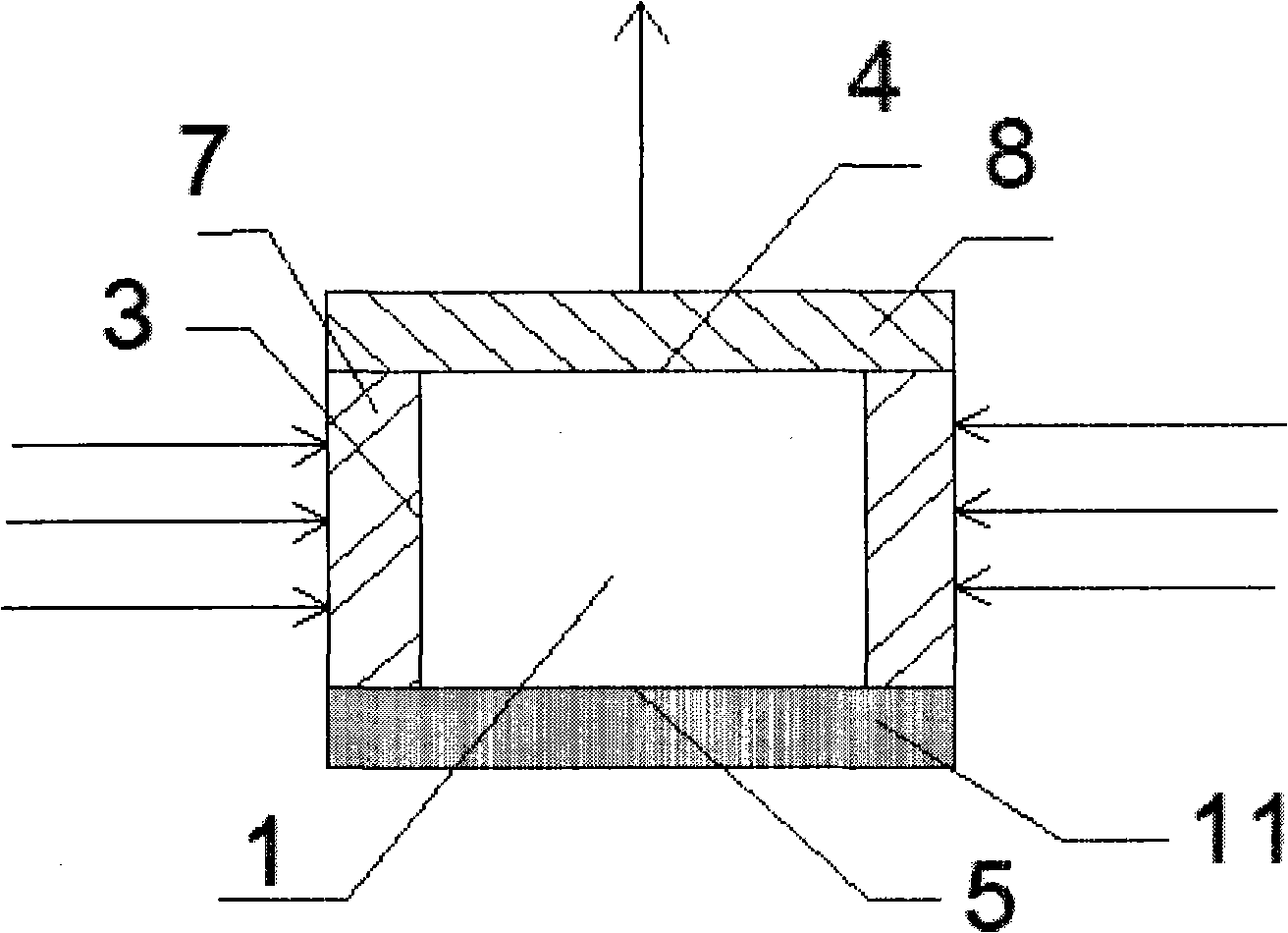

[0088] Embodiment 1: A side-entry structural light guide, such as Figure 1a The light source 6 uses 90 pieces of 3528SMD patch LEDs; it is welded on an aluminum-based printed board with a length of 165mm and a width of 10mm, and is arranged on the incident surface 3 of the solid geometric body 1. The solid geometric body 1 of the light guide is 160mm long, 65mm wide, and The PMMA plate with a thickness of 6mm has a geometric shape of a hexahedron in a solid polyhedron made of PMMA material, and has six outer surfaces; the light source 6 is arranged on two opposite sides of the hexahedron, and this side is the incident surface 3 , so there are two incident surfaces 3 in the figure, and the remaining two sides are reflective surfaces 5 . One parallel outer surface of the hexahedron is the light-emitting surface 4, and the other parallel outer surface is the reflective surface 5. This light guide is a side-entry structural light guide with incident light from the side and light o...

Embodiment 2

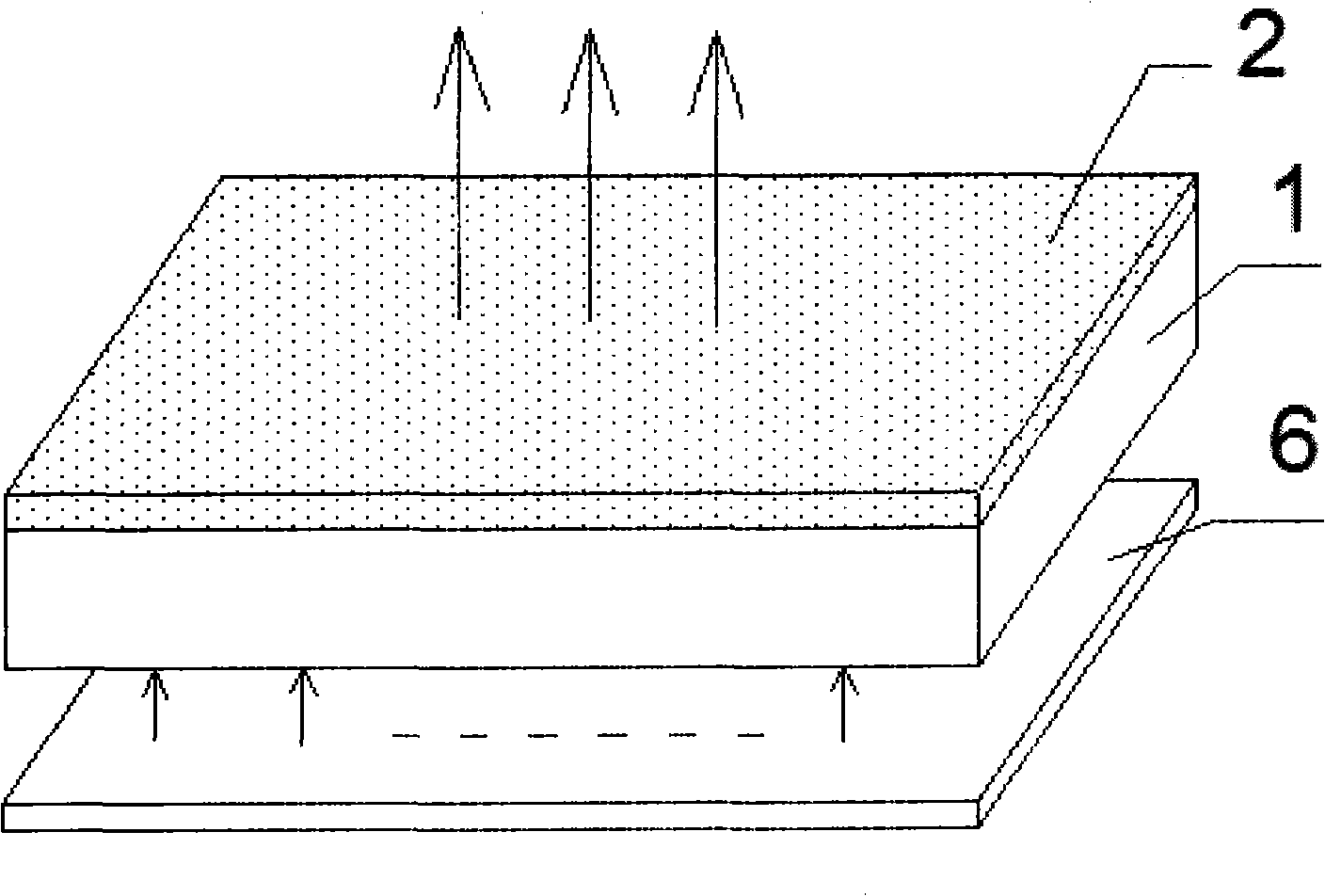

[0093] Embodiment 2: a kind of direct type structure light guide body, such as Figure 2a : The solid geometric body 1 of the light guide plate is a PMMA plate, and its geometric shape is a six-sided geometric body in a solid polyhedron, with six outer surfaces in total. The light source 6 is arranged on a parallel surface of the solid geometric body 1, then this parallel surface is the incident surface 3, and the other parallel surface is the light-emitting surface 4, (the rest of the sides are all reflective surfaces 5), the light guide plate is based on a parallel surface of the geometric body The incident light and the light exiting from another parallel surface of the geometric body is the direct-type structured light guide plate. Its light-emitting surface 4 is the light-emitting surface 4 of a direct-down structure light guide plate, which needs to be covered with a diffusion film layer 9, such as Figure 2b : In this embodiment, high-purity silica powder with a partic...

Embodiment 3

[0098] Embodiment 3: A tubular light guide plate, such as Figure 3a : The solid geometric body 1 of the light guide is a PMMA pipe, and its geometric shape is a ring-shaped geometric body in a solid rotating body. The outer surface is composed of two inner and outer curved surfaces and two bottom surfaces. The light source 6 is arranged on a bottom surface of the ring-shaped geometric body, and this bottom surface is the incident surface 3, so there is only one incident surface 3 in the figure, and the other bottom surface is the reflective surface 5. The inner curved surface of the annular geometry is also the reflective surface 5 . The outer curved surface of the ring-shaped geometric body is the light-emitting surface 4 , and the light guide is a side-entry structural light guide plate in which light is incident on a bottom surface of the ring-shaped geometric body and light is emitted from the outer curved surface of the ring-shaped geometric body. Such as Figure 3b : ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com