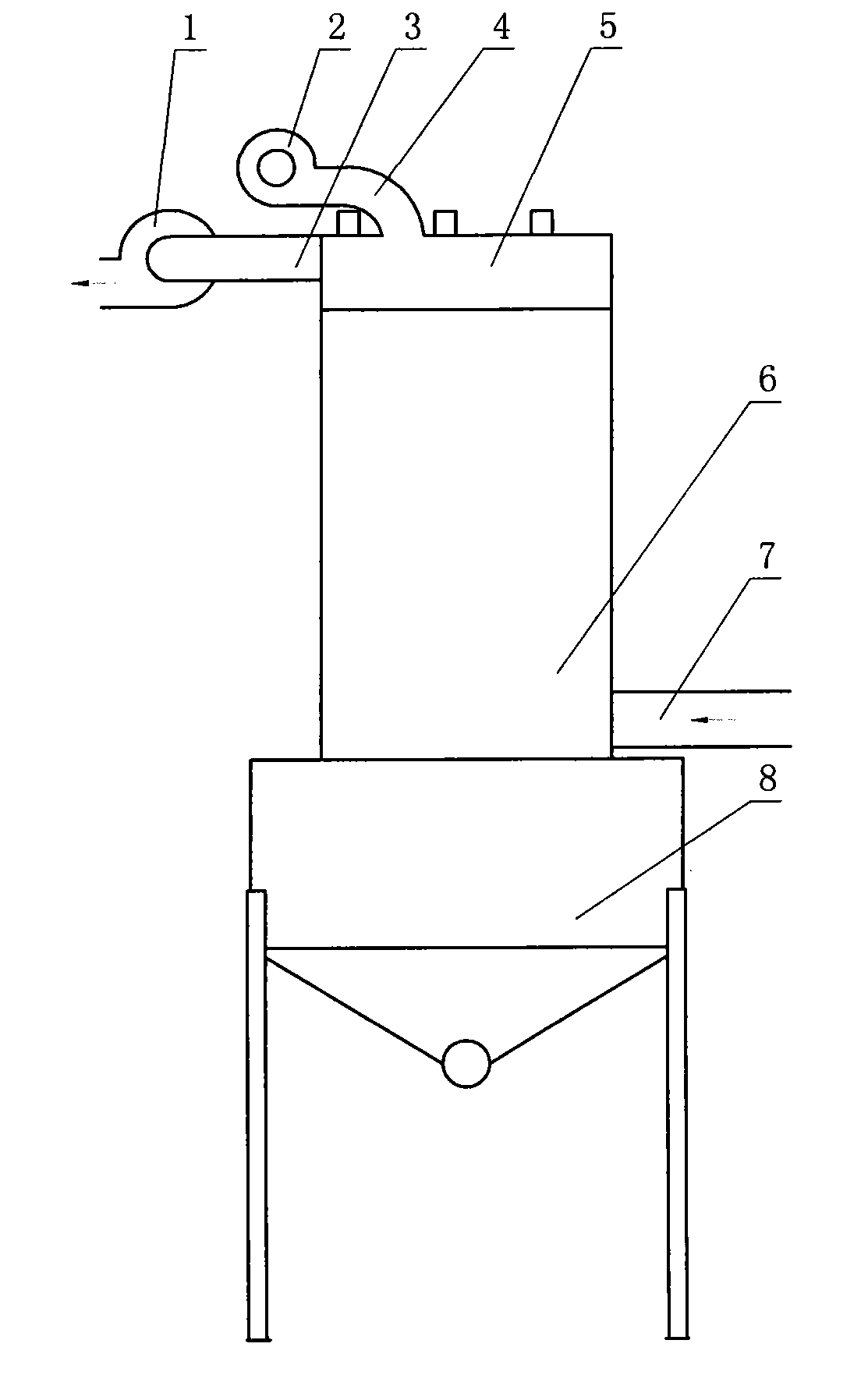

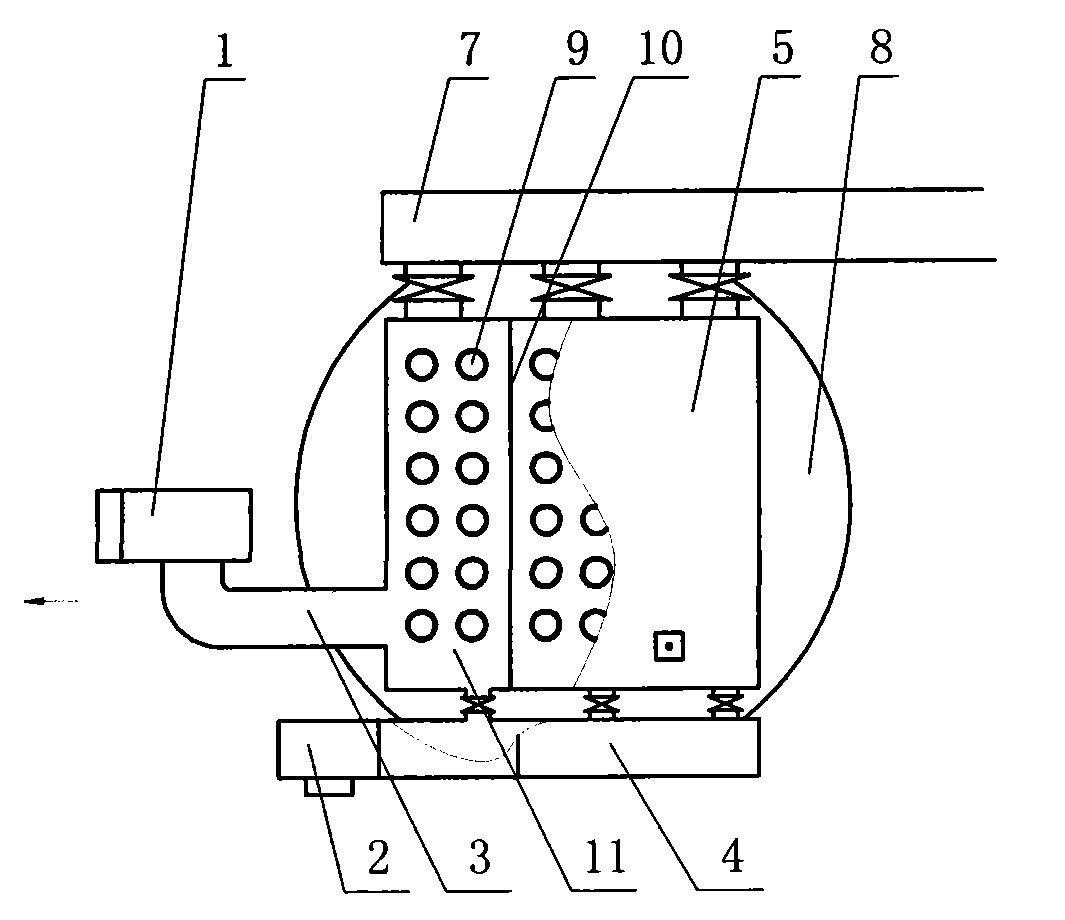

Stage blowback dust-cleaning method and equipment of air box blowback bag type dust collector

A technology of reverse blowing bag and dust collector, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of uneven dust removal on the surface of dust removal bags, reduced filtration efficiency of dust collectors, and different resistance of dust removal bags, etc. To achieve the effect of improving the cleaning effect, convenient and quick installation, and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

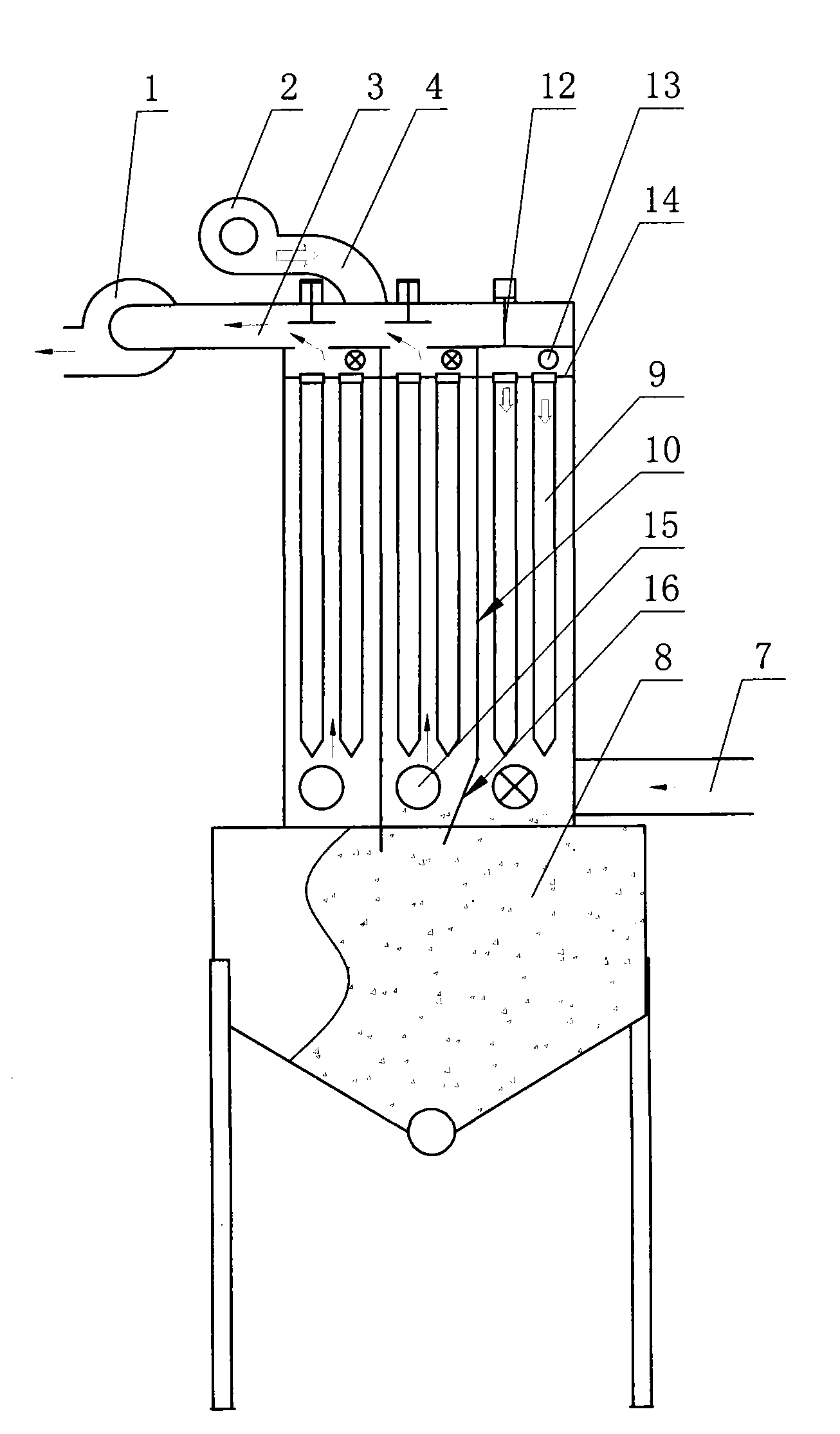

[0031] The step-by-step back-blowing dust cleaning method of the air box back-blowing bag filter, the specific steps include:

[0032] (1) Close the exhaust valve of the bag room where the dust collector needs to be cleaned, and open the blowback valve;

[0033] (2) Set the initial wind speed of the blower back to 0.3 times of the filtering wind speed, so that it can blow back the dust bag in the dust removal bag room, and the back blow time is 5s;

[0034] (3) Increase the air volume of the reverse blower to 1 time of the filtering wind speed;

[0035] (4) Continue to blow back the dust bag, the back blow time is 60s, and the dust cleaning is over.

Embodiment 2

[0037] (1) Close the exhaust valve of the bag room where the dust collector needs to be cleaned, and open the blowback valve;

[0038] (2) Set the initial wind speed of the blower back to 0.8 times of the filtering wind speed, so that it can blow back the dust bag in the dust removal bag room, and the back blow time is 2s;

[0039] (3) Increase the air volume of the reverse blower to twice the filtering wind speed;

[0040] (4) Continue to blow back the dust bag, the back blowing time is 15s, and the dust cleaning is over.

Embodiment 3

[0042] The step-by-step back-blowing dust cleaning method of the air box back-blowing bag filter, the specific steps include:

[0043] (1) Close the exhaust valve of the bag room where the dust collector needs to be cleaned, and open the blowback valve;

[0044] (2) Set the initial wind speed of the blower to twice the filtering wind speed, so that it can blow back the dust bag in the dust removal bag room, and the back blow time is 0.5s;

[0045] (3) Increase the air volume of the reverse blower to 5 times of the filtering wind speed;

[0046] (4) Continue to blow back the dust bag, the back blowing time is 2s, and the dust cleaning is over.

[0047] Working principle of the present invention is:

[0048] When the exhaust valve of the dust cleaning bag room is closed and the blowback valve is opened, the pressure of the dust cleaning bag room and the ash storage is equal. The first-stage wind blown by the reverse blower blows into the inside of the dust bag, so that the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com