Baffle plate box type filter element in use for pulse self-cleaning type air filter

An air filter and self-cleaning technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of no more than 0.5 μm, limited filtration accuracy, increased consumption, etc., to prolong life and increase Dust holding capacity and the effect of reducing resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

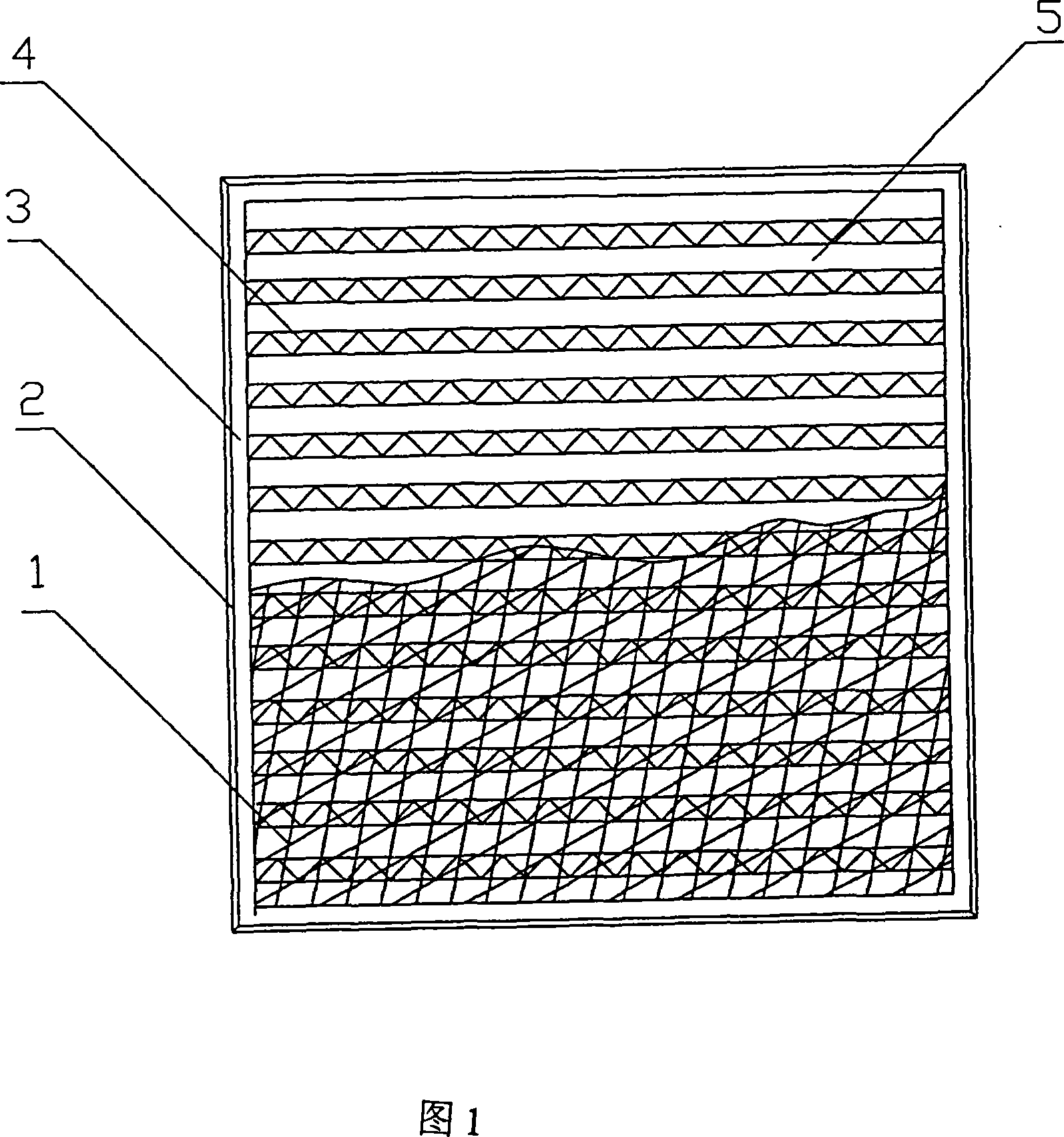

[0008] With reference to accompanying drawing 1, its structure is to comprise net 1, frame 2, sealing strip 3, clapboard 4, filter paper 5, and wherein net 1 is arranged on the outside, and frame 2 is arranged around, and inside frame 2 is sealing strip 3, several strips The separator 4 is arranged at the center of the filter core, and the filter paper 5 is between the separator 4 and the separator 4;

[0009] The shape is square and modular, and the partition is made of corrugated aluminum handkerchief.

[0010] The filter element is made of 80% fiber and 20% polyester synthetic filter paper.

[0011] When the present invention is made, at first after dividing plate 4 is formed according to the figure, the filter paper 5 that passes the inspection adopts the S-shaped method, and surrounds the dividing plate 4 layer by layer, so that filter paper 5 is stacked on the dividing plate 4 like a paper fan. At the same time, since the paper fan does not have a partition, it is in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com