Hydrolyzed fish protein powder and preparation method thereof

A technology of hydrolyzing protein powder and protein powder, which is applied in the field of food protein and food protein processing, and can solve the problems of no use of fish viscera, unutilized protease, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

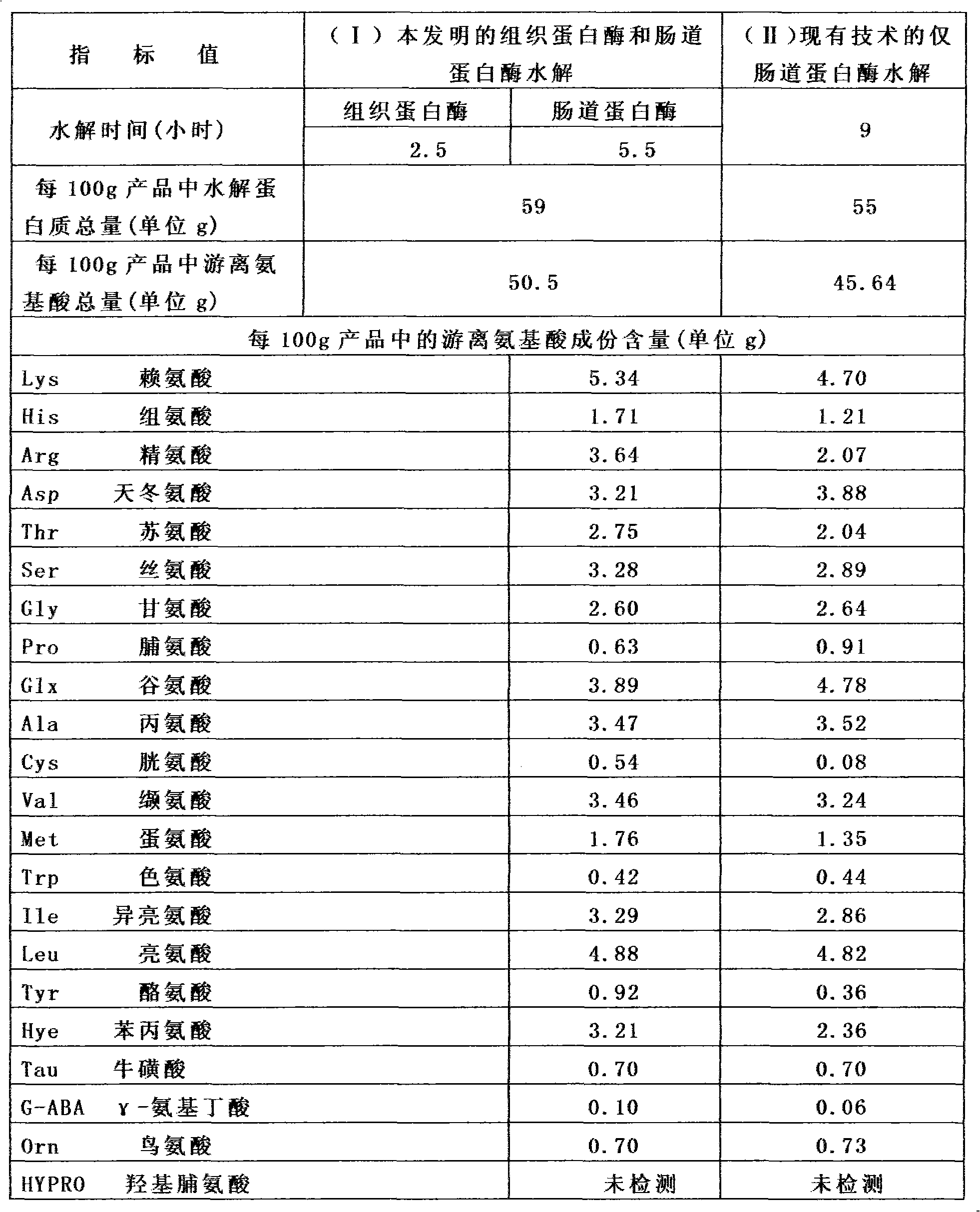

Image

Examples

Embodiment 1

[0042] A preparation method of fish hydrolyzed protein powder, the steps are as follows:

[0043] A. Determine the fish raw material used for hydrolysis: the fish raw material is all kinds of fresh water fish that have been cleaned without removing the head and viscera, specifically including: only the pre-cleaned part after cleaning The remaining fish body after the meat was harvested, or the fresh and alive whole fish after cleaning and not cleaning, or / and the fresh and alive quick-frozen fish after cleaning and not cleaning; the fish raw material in this embodiment is only The leftover fish bodies after partial meat harvesting in advance can be mixed regardless of the type and size of the fish. In this embodiment, the fresh silver carp with an average monomer weight of about 1.5kg is used to produce surimi, and the meat is harvested by a meat harvester. 30% of the remaining fish body is used as raw material for fish hydrolyzed protein powder;

[0044] B. Hydrolyze with th...

Embodiment 2

[0049] A kind of preparation method of fish hydrolyzed protein powder, the steps different from embodiment one are as follows:

[0050] A, determine that the fish raw material that is used for hydrolysis is the fresh and alive whole fish that does not clear up after cleaning; Specifically speaking, the small miscellaneous fish that takes fresh and alive loach as the main body is made raw material, also can be silver carp, carp etc.; To inhibit microorganisms, it also adopts low-temperature crushing and homogenization, processes to a particle size of 0.5-0.8 mm, and puts it in a hydrolysis reaction tank;

[0051] B. Adjusting the pH value when hydrolyzing with the cathepsin of the fish raw material itself is pH=4.5~5.0, heating 45~50°C, the present embodiment pH=5.0, heating to 50°C, or choosing pH=4.5, adding The temperature is 45-50°C; the pH value is adjusted by adding a 15% hydrochloric acid solution; in addition, in order to better activate the cathepsin of the fish raw ma...

Embodiment 3

[0055] A kind of preparation method of fish hydrolyzed protein powder, the steps different from embodiment one are as follows:

[0056] A. Determine the fish raw materials used for hydrolysis: fresh whole fish that have been cleaned but not cleaned, and fresh and live quick-frozen fish that have been cleaned but not cleaned;

[0057] The fish raw material that is used for hydrolysis only uses the fresh and alive quick-frozen fish that does not clean up after cleaning, is another kind of embodiment;

[0058] B. When hydrolyzing with cathepsin of the fish raw material itself, adjust the pH value to be pH=4.5~5.0, heat to 45~50°C, in this embodiment, pH=4.5, heat to 50°C, or select pH=5.0, Heating at 45°C; adjusting the pH value is achieved by adding a 25% hydrochloric acid solution; in addition, in order to better activate the cathepsin of the fish raw material itself, add 0.15% of the weight of the fish raw material to the hydrolyzate. as an enzyme activator;

[0059] C, fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com