Superimposition of rapid periodic and extensive post multiple substrate uv-ozone clean sequences for high throughput and stable substrate to substrate performance

A base material and ozone technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as unsuitable for semiconductor processing, uneven accumulation, uneven hardening of thin films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

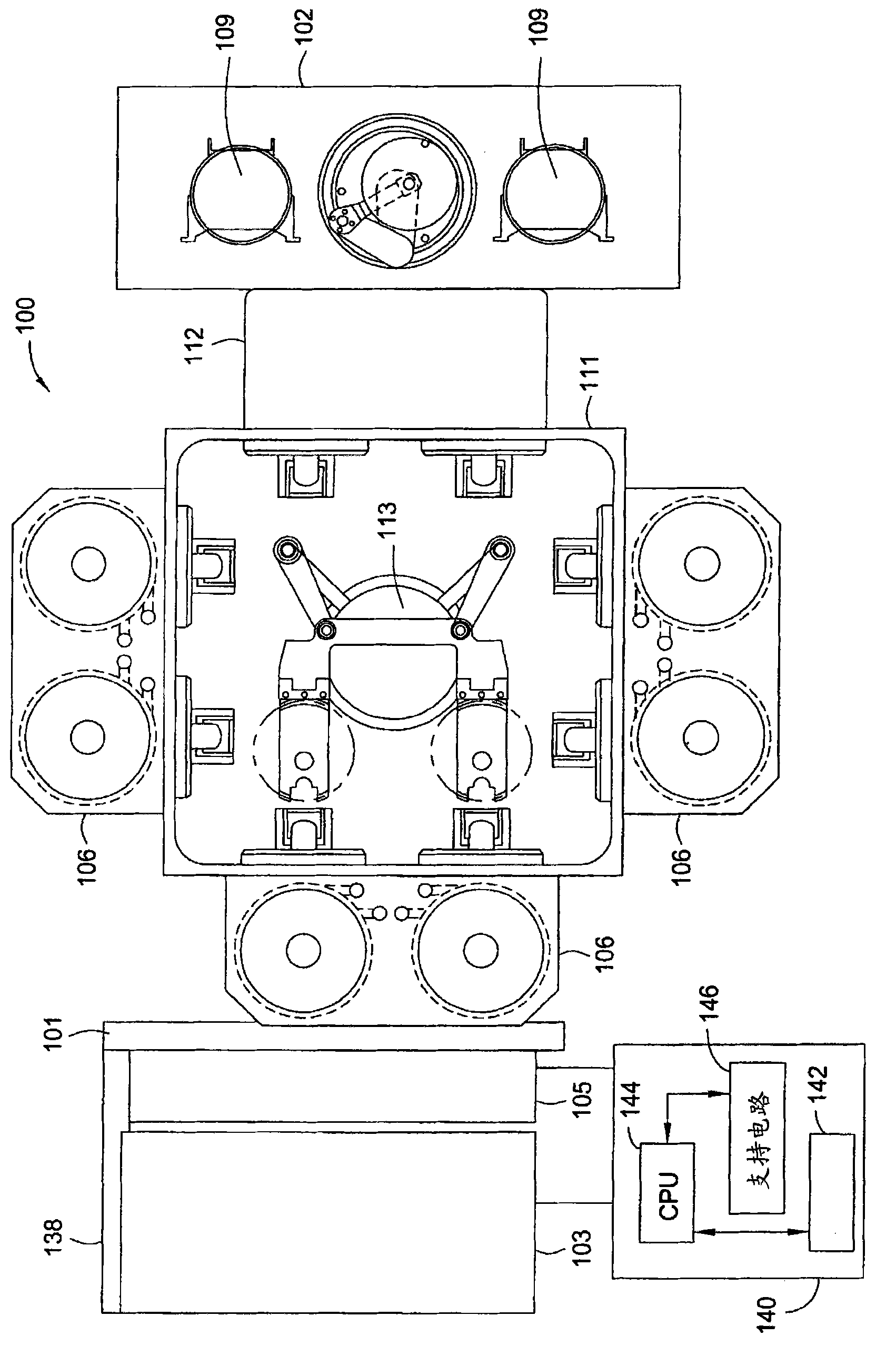

[0020] Embodiments of the present invention include methods for cleaning a substrate processing chamber using ultraviolet light and ozone to improve substrate quality and substantially reduce chamber downtime while maintaining throughput. The process chamber walls, UV windows, and pedestals can be effectively cleaned by removing residue buildup, especially in cold areas of the process chamber where more residue buildup typically occurs over time. While the present invention can be used to clean any process chamber, residues formed by ultraviolet (UV) hardening of porogens can be completely removed using embodiments of the present invention.

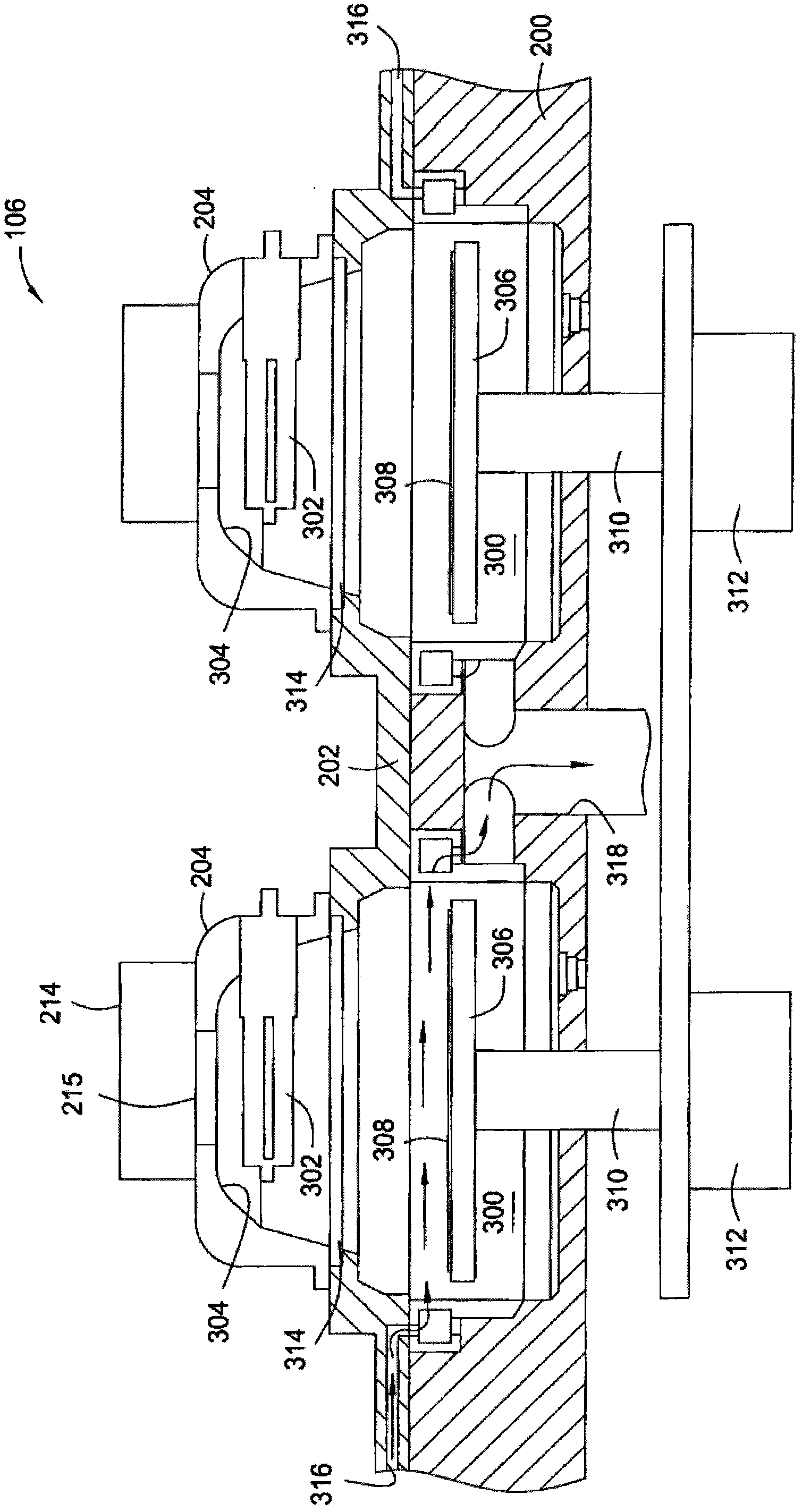

[0021] In one embodiment of a processing chamber for UV curing, a tandem processing chamber provides two separate and contiguous processing zones within a chamber body, and an upper cover having one or more bulb isolation windows, Align separately above each treatment area. The bulb isolation windows can be implemented with a window on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com