Recovery treatment device for aging oil of oil fields

A technology for recycling and aging oil, which is only applied in the direction of multi-stage series refining process treatment, etc. It can solve the problems of shortening the service life of equipment, crossing the electric field, increasing the degree of emulsification of crude oil in the system, and achieves the effect of convenient assembly and relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

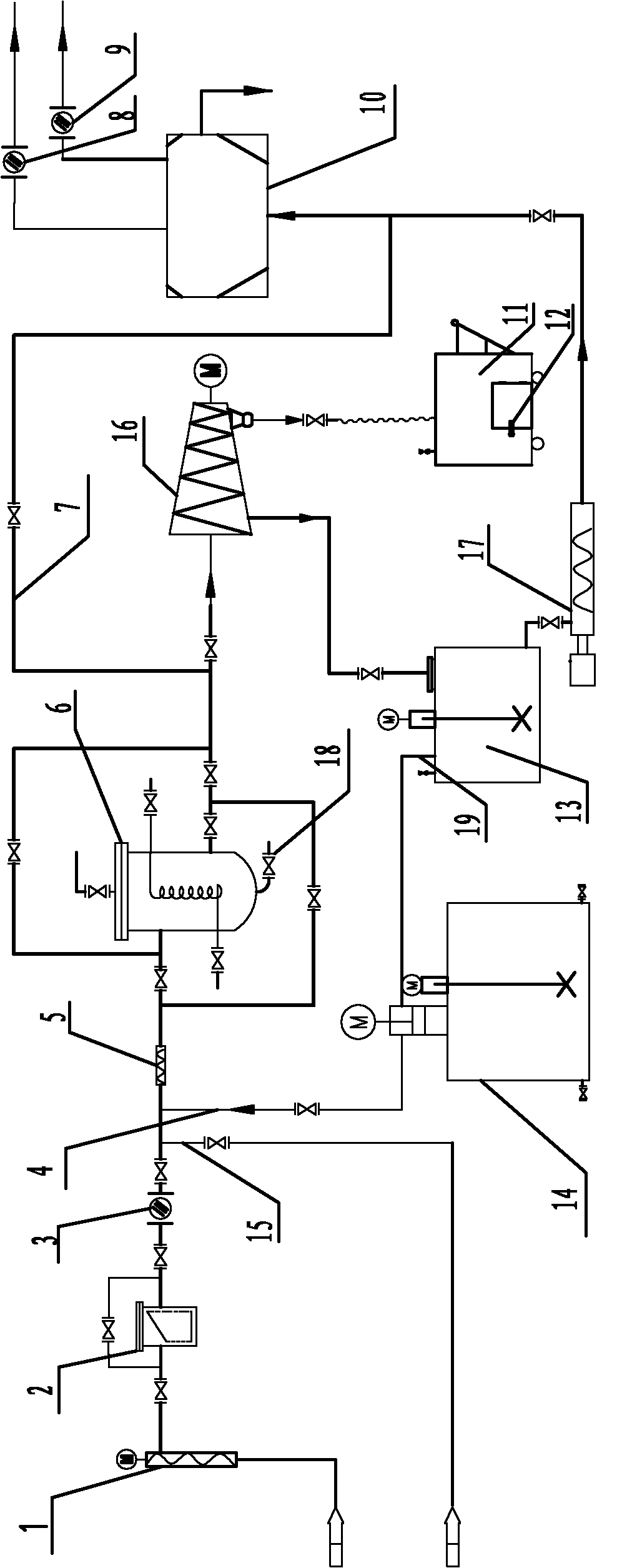

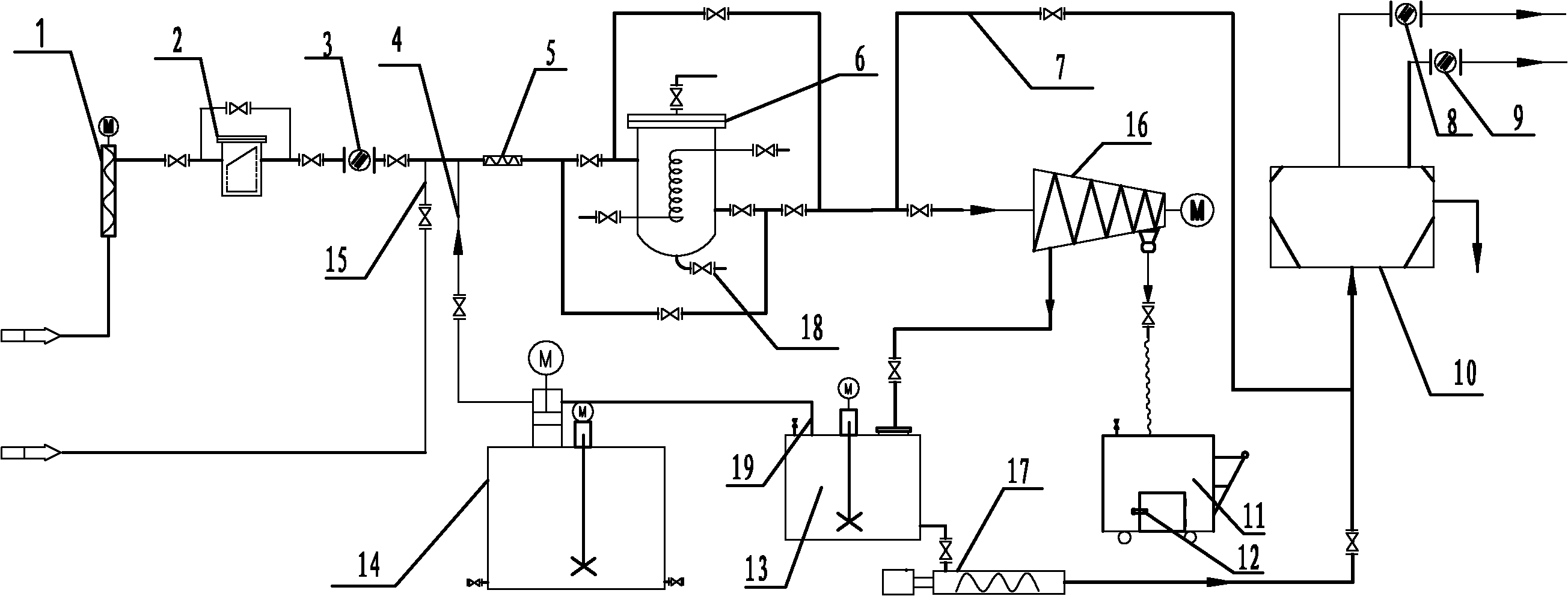

[0020] Embodiment 1: The aging oil is lifted into the skid by the screw lift pump 1, and the pressure is increased to 0.4MPa. The outlet of the screw pump 1 is connected to the blue filter 2 through a pipe. The filter is provided with a bypass pipeline, and the filter outlet is connected to the flow meter 3 through a pipe. System processing flow is about 2 ~ 3m 3 / h, the main line behind the flow meter is equipped with a hot water mixing port 15, which is drawn from the on-site 100°C electric dehydration outlet, and after the temperature rises to 50°C, it enters the chemical static mixer 5 on the main line to make the demulsifier and the mixed hot water Fully mixed in the system, the dosing point 4 is set between the water mixing port and the static mixer, the outlet of the static mixer is connected to the inlet of the separation heat exchanger 6 through the pipe, the temperature of the crude oil is raised from 50°C to higher than 85°C, and the inlet of the heat exchanger is ta...

Embodiment 2

[0021] Embodiment 2: The aging oil is lifted into the skid by the screw lift pump 1, and the pressure is increased to 0.5 MPa. The outlet of the screw pump 1 is connected to the blue filter 2 through a pipe. The filter is provided with a bypass pipeline, and the filter outlet is connected to the flow meter 3 through a pipe. The system handles a flow of about 2m 3 / h, there is a dosing point behind the flowmeter, and then it enters the chemical static mixer 5 on the main line to fully mix the demulsifier and the hot water mixed in the system, and the outlet of the static mixer is connected to the inlet of the separation heat exchanger 6 through the pipe , the crude oil temperature rises from 40°C to higher than 75°C, and the inlet of the heat exchanger enters in a tangential direction. A slag discharge port 18 is provided at the bottom of the heat exchanger to remove a small amount of solid residue in the aged oil. The pipeline 7 directly enters the vortex type oil-water separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com