Quaternary ammonium salt positive ion-type organic polymeric flocculant and preparation method thereof

A quaternary ammonium salt cation, organic polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems that have not been reported in the literature, and achieve the effect of ideal effect, good stability and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

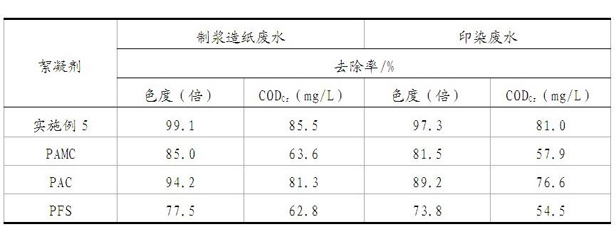

Examples

Embodiment 1

[0042] The raw materials and mass parts of a quaternary ammonium salt cationic organic polymer flocculant are: dimethylamine: 50 parts; urea: 2 parts; epichlorohydrin: 20 parts; water: 1 part; catalyst: 1 part ; Cross-linking agent: 8 parts.

[0043] The specific steps for preparing the flocculant are:

[0044](1) Add urea, dimethylamine, catalyst, and water into the reactor in sequence according to the mass fraction at 50°C, and stir until the urea is completely dissolved and mixed evenly;

[0045] (2) Add epichlorohydrin dropwise to the reaction system. After the dropwise addition, slowly raise the temperature of the reaction system to 95°C;

[0046] (3) Add a cross-linking agent, react for 4 hours and cool to room temperature to obtain a light yellow organic polymer liquid product containing quaternary amine groups;

[0047] (4) Purify the obtained product with acetone-absolute ethanol at a volume ratio of 1:1, and dry it at 85°C to obtain a light yellow organic polymer p...

Embodiment 2

[0051] The raw materials and mass parts of a quaternary ammonium salt cationic organic polymer flocculant are: dimethylamine: 5 parts; urea: 45 parts; epichlorohydrin: 30 parts; water: 10 parts; catalyst: 2 parts .

[0052] The specific steps for preparing the flocculant are:

[0053] (1) Add urea, dimethylamine, catalyst, and water to the reactor in sequence according to the mass fraction at 60°C, and stir until the urea is completely dissolved and mixed evenly;

[0054] (2) Add epichlorohydrin dropwise to the reaction system, and after the dropwise addition, slowly raise the temperature of the reaction system to 75°C;

[0055] (3) Add a cross-linking agent, react for 7 hours and then cool to room temperature to obtain a light yellow organic polymer liquid product containing quaternary amine groups;

[0056] (4) Purify the obtained product with acetone-absolute ethanol at a volume ratio of 1:2, and dry it at 85°C to obtain a light yellow organic polymer powder product.

[...

Embodiment 3

[0060] The raw materials and mass parts of a quaternary ammonium salt cationic organic polymer flocculant are: dimethylamine: 45 parts; urea: 30 parts; epichlorohydrin: 35 parts; water: 20 parts; catalyst: 5 parts ; Cross-linking agent: 3 parts.

[0061] The specific steps for preparing the flocculant are:

[0062] (1) Add urea, dimethylamine, catalyst, and water to the reactor in sequence according to the mass fraction at 55°C, and stir until the urea is completely dissolved and mixed evenly;

[0063] (2) Add epichlorohydrin dropwise to the reaction system. After the dropwise addition, slowly raise the temperature of the reaction system to 80°C;

[0064] (3) Add a cross-linking agent, react for 6 hours and then cool to room temperature to obtain a light yellow organic polymer liquid product containing quaternary amine groups;

[0065] (4) Purify the obtained product with acetone-absolute ethanol at a volume ratio of 1:3, and dry it at 85°C to obtain a light yellow organic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com