Preparation method of wolfram carbide-carbon (WC-C) composite material with large specific surface area

A composite material, WC-C technology, used in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve problems such as performance barriers, low specific surface area, etc., to reduce carbonization time and temperature, high specific surface area, Preparing convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

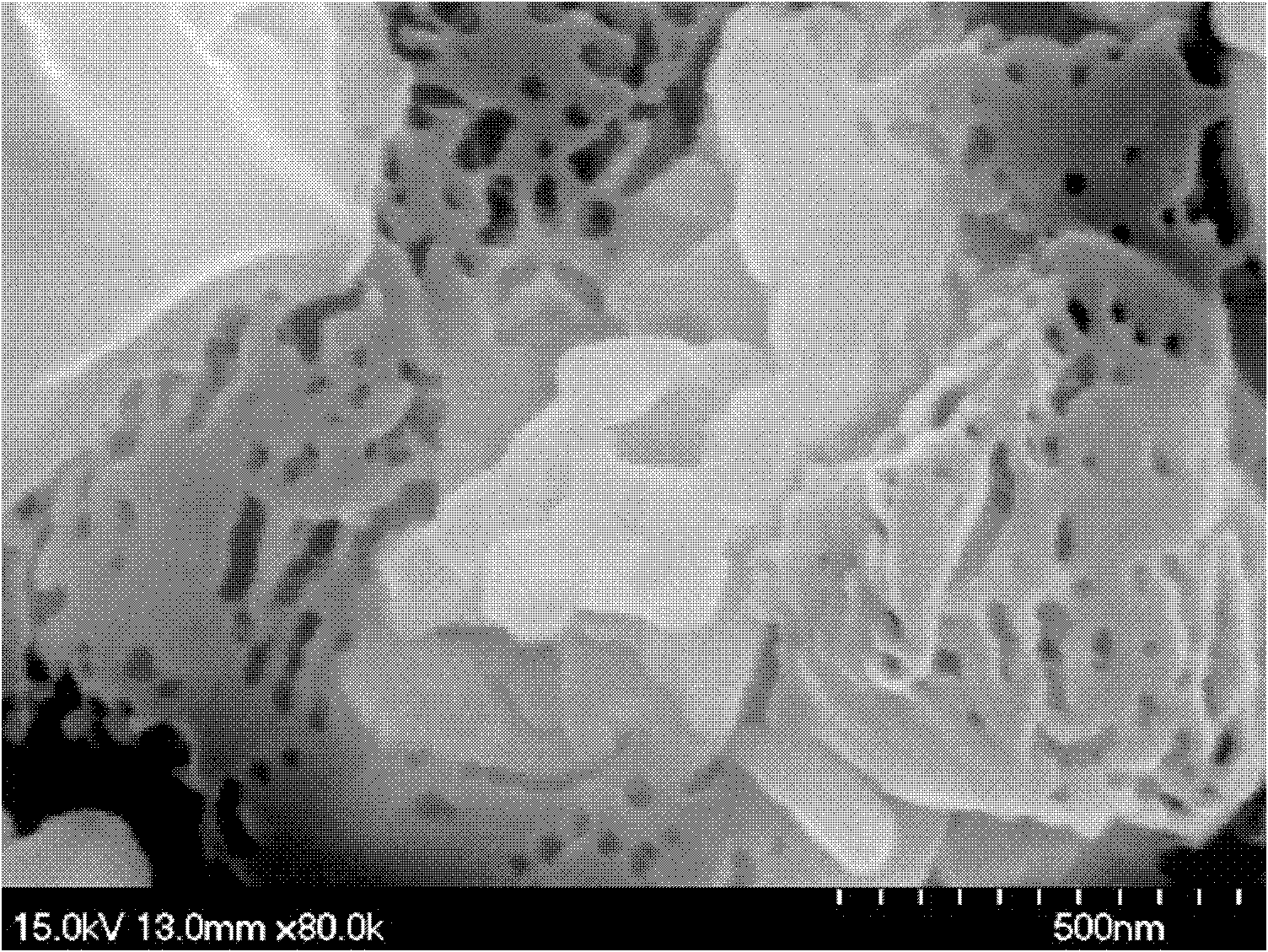

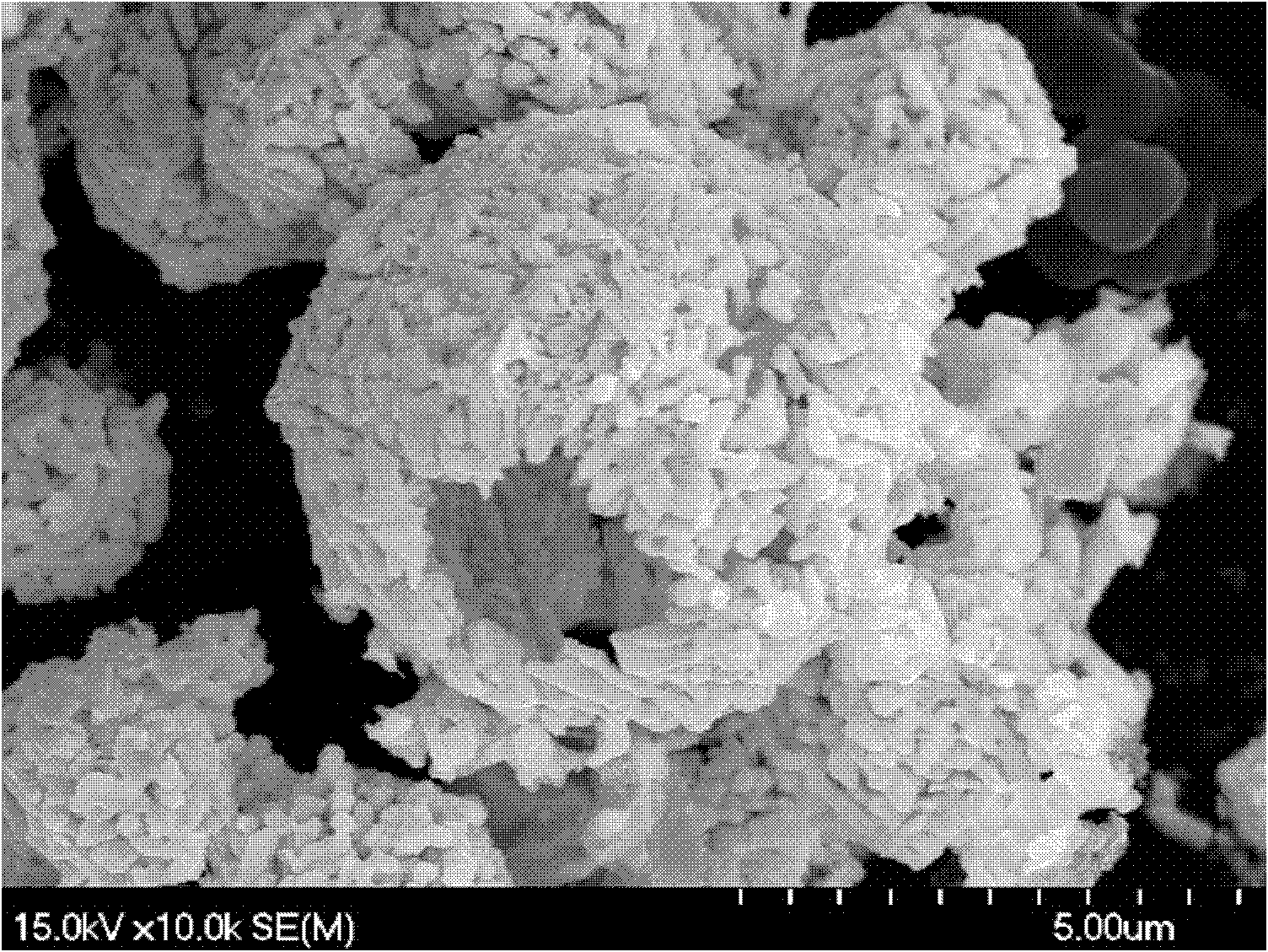

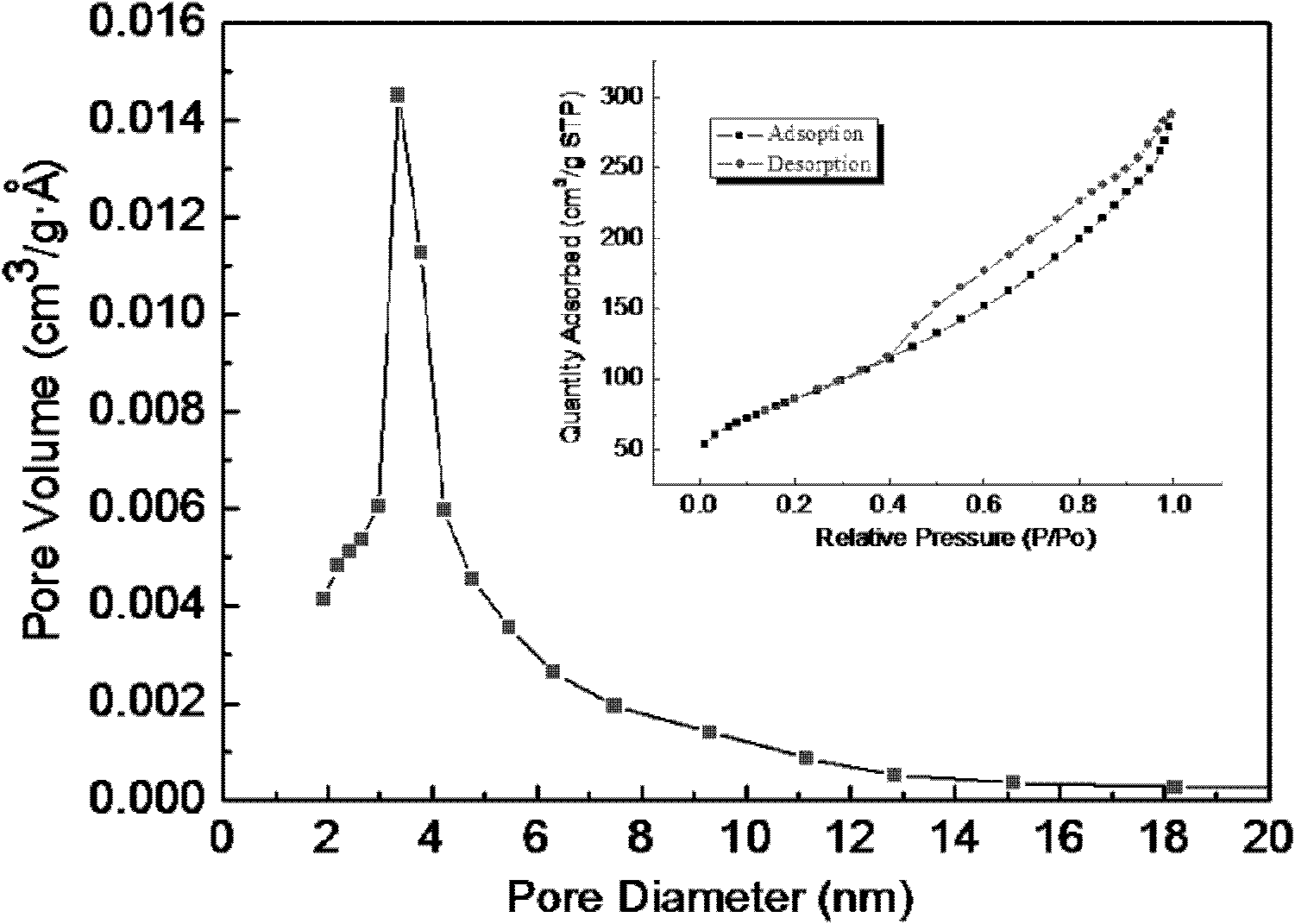

Embodiment 1

[0021] Ammonium metatungstate is used as the precursor and magnesium powder is used as the reduction catalyst. Under the protection of nitrogen, the ammonium metatungstate and magnesium powder with a mass ratio of 1:0.2 are evenly mixed and put into the quartz boat, and then moved into the tube type with nitrogen gas. in the furnace. Reductive carbonization was carried out in a tube furnace in a temperature-programmed manner using 100 ml / min of CO as the carbonization gas. The temperature programming rate was 5°C / min. Heat at 850°C for 4 hours. After the reaction is completed, cool down to room temperature under the protection of nitrogen, put the sample into hydrochloric acid solution to remove the metal, filter and dry, and obtain a black powder which is the high specific surface area WC-C composite material. Its specific surface test result is 287.2m 2 / g.

Embodiment 2

[0023] The spray-dried spherical ammonium metatungstate is used as the precursor, and the magnesium powder is used as the reduction catalyst. Under the protection of nitrogen, the ammonium metatungstate and magnesium powder with a mass ratio of 1:0.5 are evenly mixed and put into the quartz boat, and then moved into the in a tube furnace with nitrogen. Reductive carbonization was carried out in a tube furnace in a temperature-programmed manner using 150 ml / min of CO as the carbonization gas. The temperature programming rate was 10°C / min. Keep warm at 900°C for 4 hours. After the reaction is completed, cool down to room temperature under the protection of nitrogen, put the sample into hydrochloric acid solution to remove the metal, filter and dry, and obtain a black powder which is the high specific surface area WC-C composite material. Its specific surface test result is 309.7m 2 / g.

Embodiment 3

[0025] Ammonium metatungstate is used as a precursor, magnesium powder is used as a reduction catalyst, and ammonium metatungstate and magnesium powder with a mass ratio of 1:1 are evenly mixed under the protection of nitrogen, put into a quartz boat, and then moved into a tube with nitrogen. in the furnace. Reductive carbonization was carried out in a tube furnace in a temperature-programmed manner using 150 ml / min of CO as the carbonization gas. The temperature programming rate was 4°C / min. Heat at 900°C for 3 hours. After the reaction is completed, cool down to room temperature under the protection of nitrogen, put the sample into hydrochloric acid solution to remove the metal, filter and dry, and obtain a black powder which is the high specific surface area WC-C composite material. Its specific surface test result is 330.2m 2 / g.

[0026] Example 3

[0027] Ammonium metatungstate is used as the precursor and aluminum powder is used as the reduction catalyst. Under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com