Composite materials

A technology of composite materials and resin materials, which is applied in the field of manufacturing fiber-reinforced composite materials, can solve the problems of reducing the mechanical properties of compression and structural parts, etc., and achieve the effect of low adhesion and mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

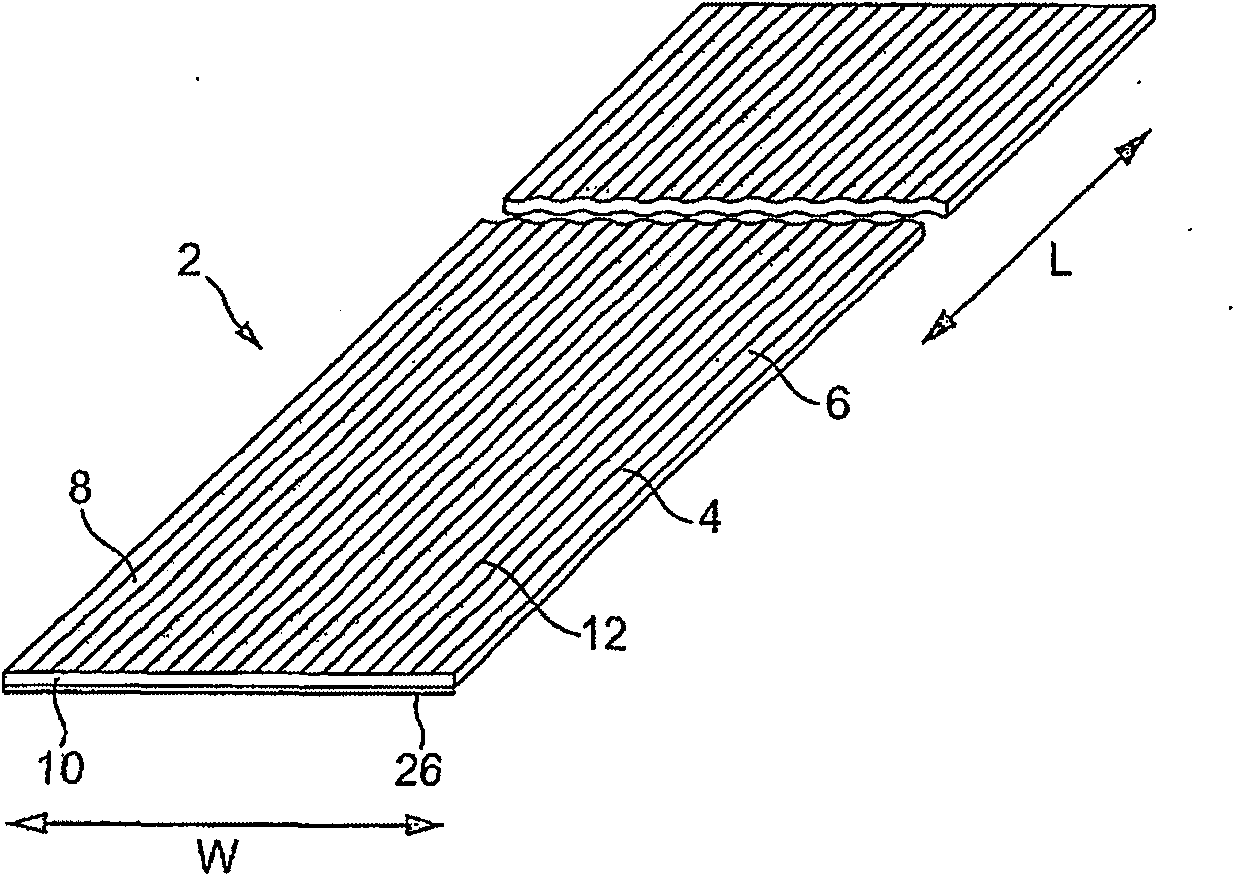

Image

Examples

Embodiment 1

[0155] In this example, a sixteen-layer multilayer laminate of an elongated prepreg of the present invention was formed to make an elongated rod. Each prepreg is made of 1600g / m2 impregnated with 32wt% epoxy resin 2 Constructed of 4800tex unidirectional E-glass fibers, these epoxy resins are referred to as "Resin Example 1" and have the properties summarized below, resulting in a final cured laminate thickness of 20mm.

[0156] Resin "Resin Example 1" comprises an epoxy resin having the following properties:

[0157] Thermal reactivity was measured using a differential scanning calorimeter (Mettler Toledo DSC821E) as a feature. The program used was to increase the temperature from 25°C to 250°C at a rate of 10°C / min, then cool to 25°C and increase to 150°C.

[0158] ΔH (J / g) 242

[0159] T 初始 (℃) 133.4

[0160] T 峰顶 (℃) 150

[0161] T 终止 (°C) 181.2

[0162] Cold Tg2(℃) 9.7

[0163] UTg2(°C) 104.5

[0164] Viscoelasticity measurements can be made at application tempe...

Embodiment 2 and comparative example 2-6

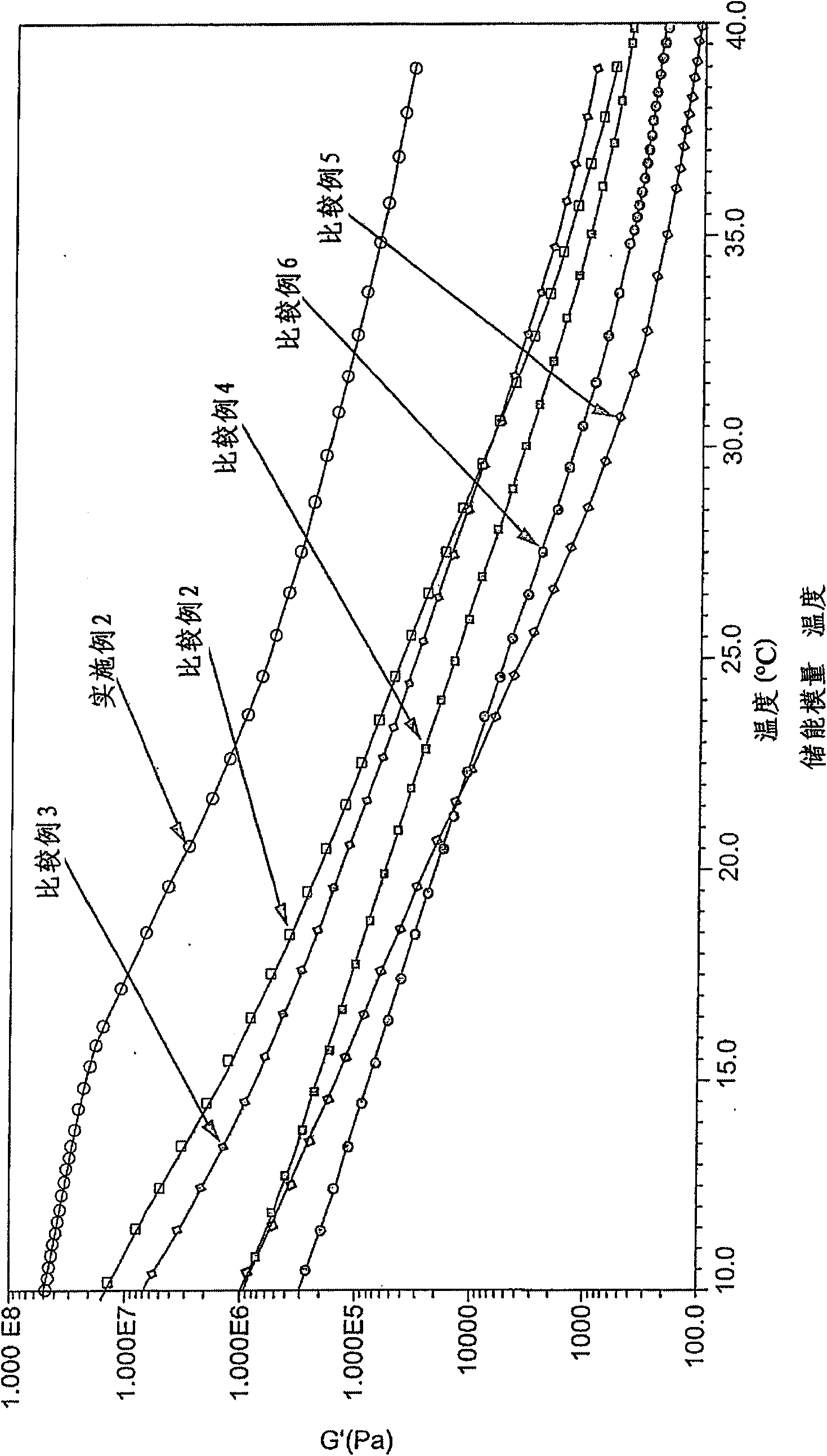

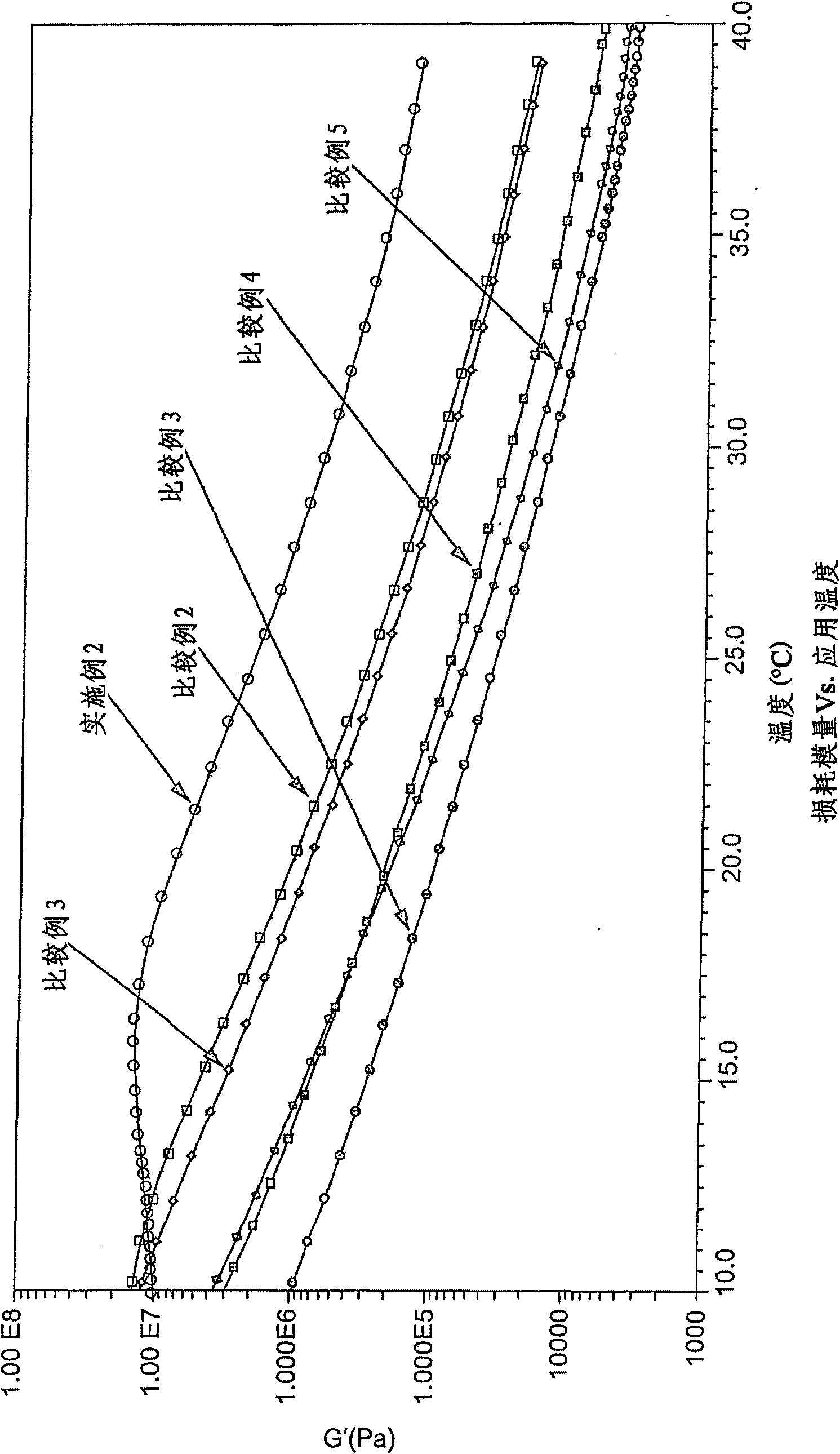

[0194] Experiments were carried out in two modes using a rheometer to test and characterize the rheological properties of prepregs.

[0195] In the first flow experiment, a constant shear stress was applied to the prepreg and the shear strain was recorded. This test is used to characterize the lower viscosity properties of a prepreg to achieve resin flow and wet-out during its cure cycle.

[0196] In a third experiment, vibratory shear strain testing was used to study viscoelastic properties at typical prepreg lay-up temperatures to characterize the material's higher viscosity and viscoelastic handling properties.

[0197] Prepregs known in the art (see Comparative Examples 2-6) and prepregs according to an embodiment of the present invention (see Example 2) were tested using the above-mentioned TA Instruments AR2000 rheometer having a disposable aluminum plate with a diameter of 25 mm. Characterization was performed to measure its storage modulus, loss modulus and complex vi...

Embodiment 3-5 and comparative example 7-10

[0206] Seven resins were tested to determine the relationship between their phase angle δ and temperature. Figure 13 It is a graph showing the relationship between phase angle δ and temperature of seven resins in Examples 3-5 of the present invention and Comparative Examples 7-10.

[0207] It can be seen that for Examples 3-5, the transition between low and high phase angles δ (indicated by a sharp change in phase angle δ) occurs in the temperature range of 10-25°C. This means that at least one temperature value within this range, the phase angle δ has a value of 50-70°, which in turn shows that at least one temperature value within this temperature range, the resin has low tack and Good combination of deformability. Prepregs containing such resins can be deformed, yet have good inter-ply venting of any air present between adjacent prepreg layers during vacuum consolidation.

[0208]In contrast, for Comparative Examples 7-10, the transition between low phase angle δ and hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex viscosity | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com