Multi-component gradient-doping GaN UV (Ultraviolet) light cathode material structure and manufacture method thereof

A technology of gradient doping and cathode material, which is applied in the manufacture of light-emitting cathodes, photo-emission cathodes, main electrodes of discharge tubes, etc., can solve the problems of small escape ratio of photoexcited electrons, improve the overall quantum efficiency and increase the escape depth. , the effect of high UV sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

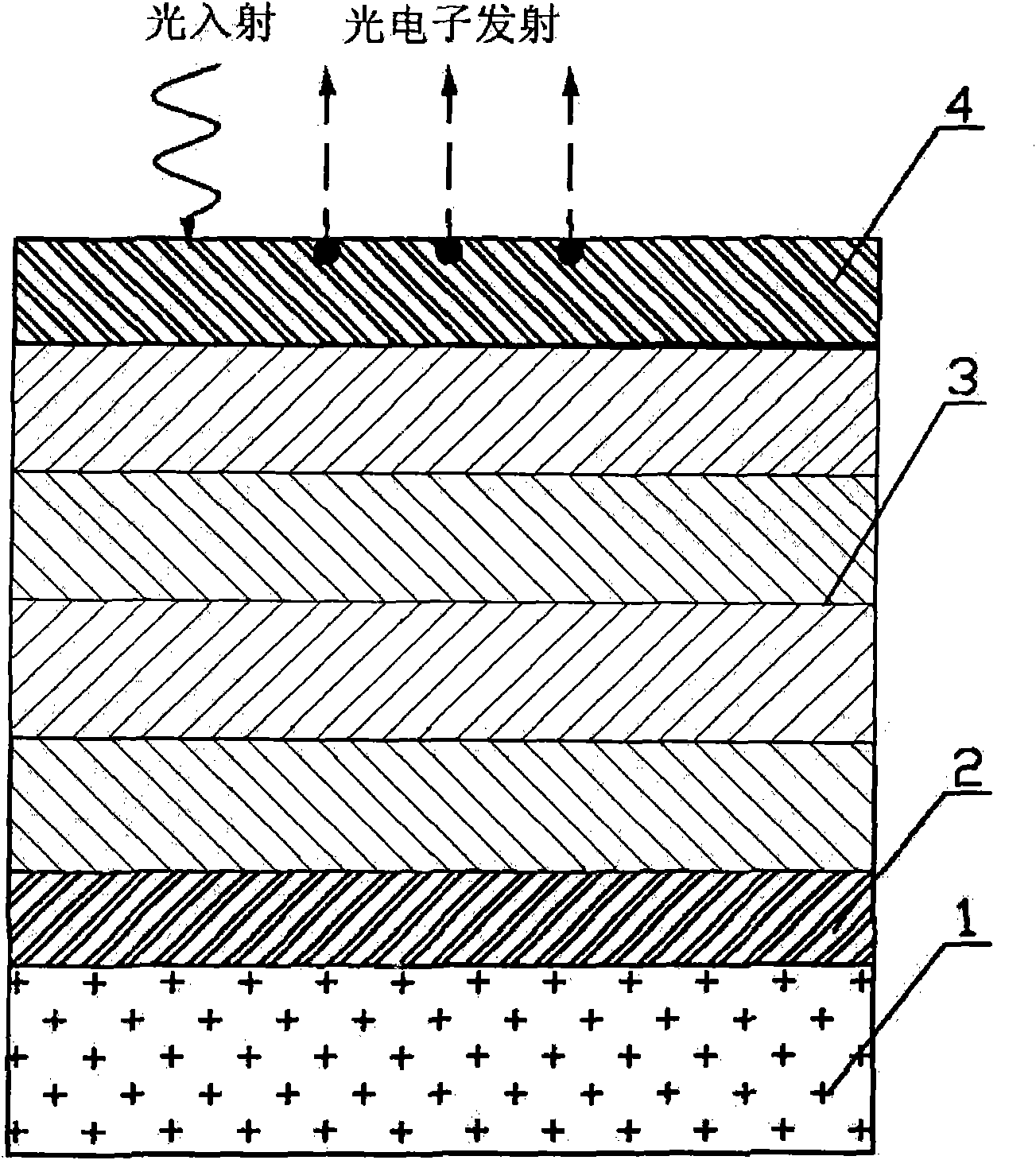

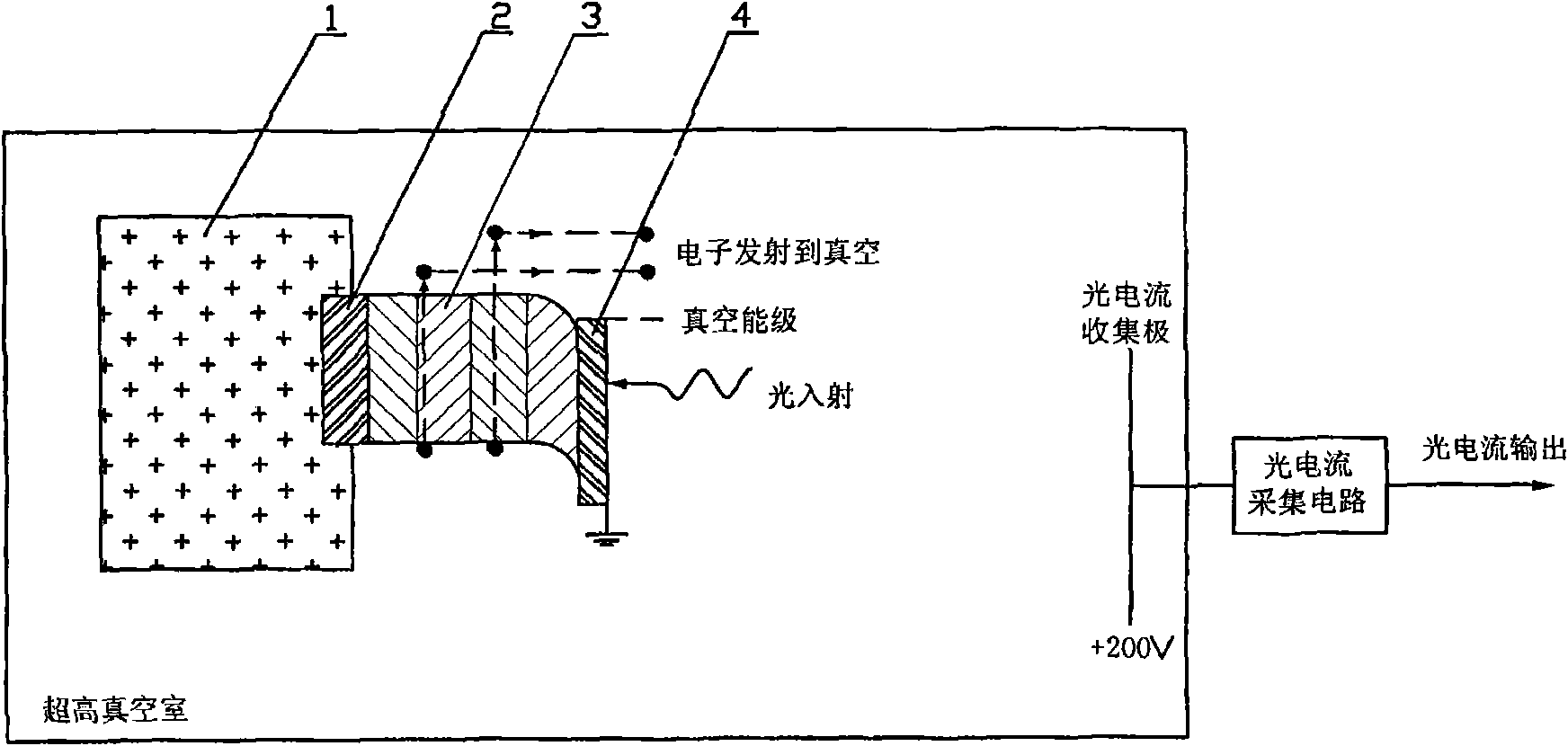

[0024] Embodiment 1: as figure 1 As shown, a reflective GaN ultraviolet photocathode material structure, the material structure consists of substrate 1 (such as sapphire), unintentionally doped AlN buffer layer 2, p-type Ga x Al 1-x N multi-component mixed crystal photoemissive layer 3 and Cs or Cs / O active layer 4; wherein, unintentionally doped AlN buffer layer 2 is epitaxially grown on the substrate layer 1 with a thickness of 50nm; p-type Ga x Al 1-x The N multi-component mixed crystal photoelectric emission layer 3 is epitaxially grown on the aforementioned AlN buffer layer 2 with a thickness of 120 nm and a doping concentration of 1×10 18 , 4×10 17 , 2×10 17 and 6×1016 , gradually decreases from the body to the body surface, the proportion control parameter x in the mixed crystal takes the AlN buffer layer as the growth starting point, and gradually changes from 0 to 1; the Cs active layer 4 is adsorbed on the p-type Ga x Al 1-x On the front surface of the N multi-...

Embodiment 2

[0025] Embodiment 2: Different from Embodiment 1, the thickness of the AlN buffer layer is 100nm; p-type Ga x Al 1-x The N multi-component mixed crystal photoelectric emission layer 3 is epitaxially grown on the aforementioned AlN buffer layer 2 with a thickness of 120 nm and a doping concentration of 1×10 18 , 4×10 17 , 2×10 17 and 6×10 16 , gradually decreases from the body to the body surface, the proportion control parameter x in the mixed crystal takes the AlN buffer layer as the growth starting point, and gradually changes from 0 to 1; the Cs active layer 4 is adsorbed on the p-type Ga x Al 1-x On the front surface of the N multi-component mixed crystal photoelectric emission layer 3, the thickness is one monoatomic layer.

Embodiment 3

[0026] Embodiment 3: Different from Embodiment 1, the thickness of the AlN buffer layer is 100nm; p-type Ga x Al 1-x The N multi-component mixed crystal photoelectric emission layer 3 is epitaxially grown on the aforementioned AlN buffer layer 2 with a thickness of 150 nm and a doping concentration of 1×10 18 , 4×10 17 , 2×10 17 and 6×10 16 , gradually decreases from the body to the body surface, the proportion control parameter x in the mixed crystal takes the AlN buffer layer as the growth starting point, and gradually changes from 0 to 1; the Cs active layer 4 is adsorbed on the p-type Ga x Al 1-x On the front surface of the N multi-component mixed crystal photoelectric emission layer 3, the thickness is one monoatomic layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com