Speed reducer

A reducer, gear shaft technology, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of low efficiency, high manufacturing cost and high cost of worm gear reducer and bevel gear reducer. Non-linear coupling problems, long service life, and the effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

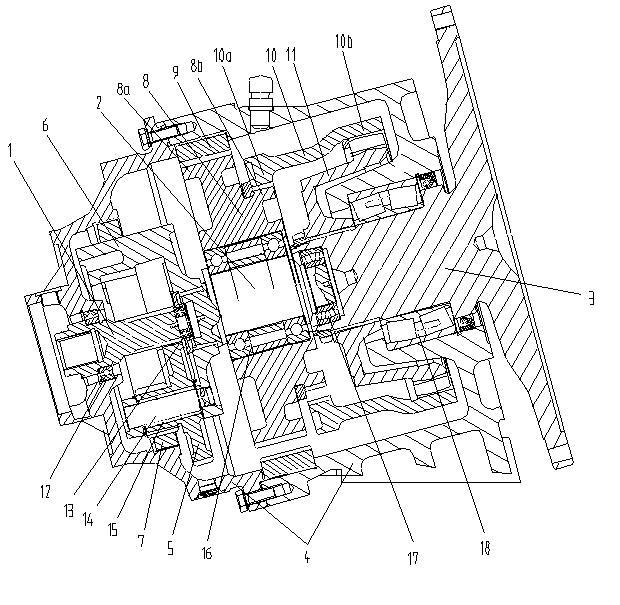

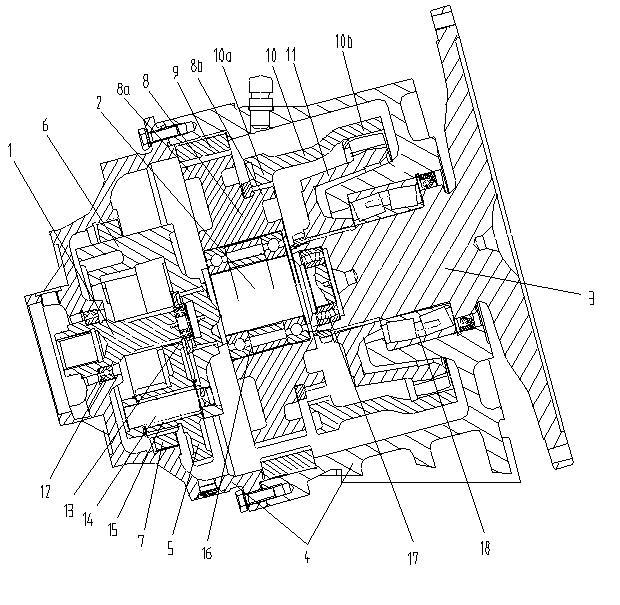

[0022] The accompanying drawing is a schematic diagram of the general assembly structure of the reducer.

[0023] As shown in the figure, the speed reducer of the present invention includes a power input gear shaft 1, a first-stage planetary gear transmission assembly, an eccentric shaft 2 whose axis deviates parallel to the axis of the power input gear shaft, a two-stage double planetary gear transmission assembly, and a power output gear Shaft 3 and reducer housing 4;

[0024] The first-stage planetary gear transmission assembly includes: a first-stage planetary gear 5, a planet carrier 6, and a first-stage sun gear 7; the first-stage planetary gear 5 meshes with the power input gear shaft 1, and the first-stage sun gear 7 is fixedly arranged In the reducer housing 4, the planet carrier 6 is in transmission cooperation with the eccentric shaft 2;

[0025] The two-stage double planetary gear transmission assembly includes: a two-stage double planetary gear 8, a two-stage sun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com