Process method for synchronously producing pueraria starch and pueraria flavonoid

A technology of Pueraria starch and Pueraria flavonoids, which is applied in the field of extraction of medicinal plant components, can solve the problems of waste of resources, failure to obtain starch at the same time, and low waste utilization rate, and achieve the effects of resource conservation and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

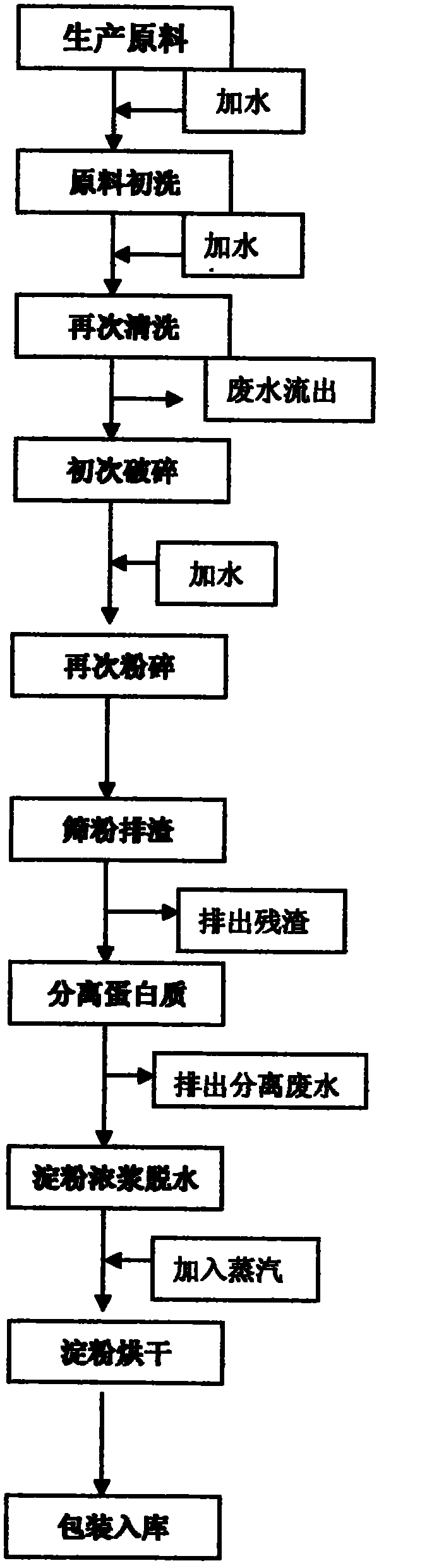

Method used

Image

Examples

Embodiment 1

[0023] Get 100kg of fresh kudzu root raw material, rough wash with water, remove silt; Wash again, remove the waste water that cleans silt; Raw material is carried out preliminary pulverization, and raw material piece adds water to pulverize (milling) again, and water consumption is 10 times of raw material; Carry out powder sieving and slag removal, the filter screen aperture is 120 mesh, and the filtrate is water-containing starch slurry, and the kudzu root residue is separated and dried for later use; the kudzu root starch slurry is separated to remove protein, and the separated waste water is set aside; the kudzu root starch concentration The pulp is dehydrated, dried with steam, and dried to obtain 17 kg of pueraria starch, the starch water content is less than 14%, and the powder yield is 17%.

Embodiment 2

[0025] Get fresh kudzu root raw material 100kg, rough wash with water, remove silt; Wash again, and remove the waste water that cleans silt; Pueraria lobata raw material is carried out preliminary pulverization, and raw material fragment adds water and pulverizes (milling) again, and water consumption is 10% of raw material. times; carry out powder sieving and slag removal, the filter screen aperture is 120 mesh, the filtrate is water-containing starch slurry, and the kudzu root residue is separated by filtration and dried for later use. Use 60% ethanol as the extraction solvent, the material ratio is 1:10, the solvent is added in two times, heated and refluxed in the reflux extraction vessel for two extractions, the extract is filtered, the extracts are combined, concentrated and ethanol is recovered, and the extract is concentrated to 12L, on a macroporous adsorption resin column, the column height-to-diameter ratio is 5:1; the filling material is D-101 resin, and the resin d...

Embodiment 3

[0027] Get 100kg of fresh kudzu root raw material, rough wash with water, remove silt; Wash again, remove the waste water that cleans silt; Raw material is carried out preliminary pulverization, and raw material piece adds water to pulverize (milling) again, and water consumption is 10 times of raw material; Sieve powder and remove slag, the pore size of the filter screen is 120 mesh, the filtrate is aqueous starch slurry, the kudzu root residue is separated, dried, and used for later use; the kudzu root starch slurry is separated to remove protein, and the separated waste water is used for later use. Collect the separated waste water, which is about 700L. The waste water is left to settle, and the supernatant is absorbed and passed directly through the macroporous adsorption resin column. The filler is D-101 resin; the column height-to-diameter ratio is 5:1; Wet packing column volume meter); after the waste water passes through the resin, the flavonoids are adsorbed in the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com