Silt curing agent and preparation method thereof

A technology for curing agent and sludge is applied in the field of preparation of sludge curing agent and curing agent for curing sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

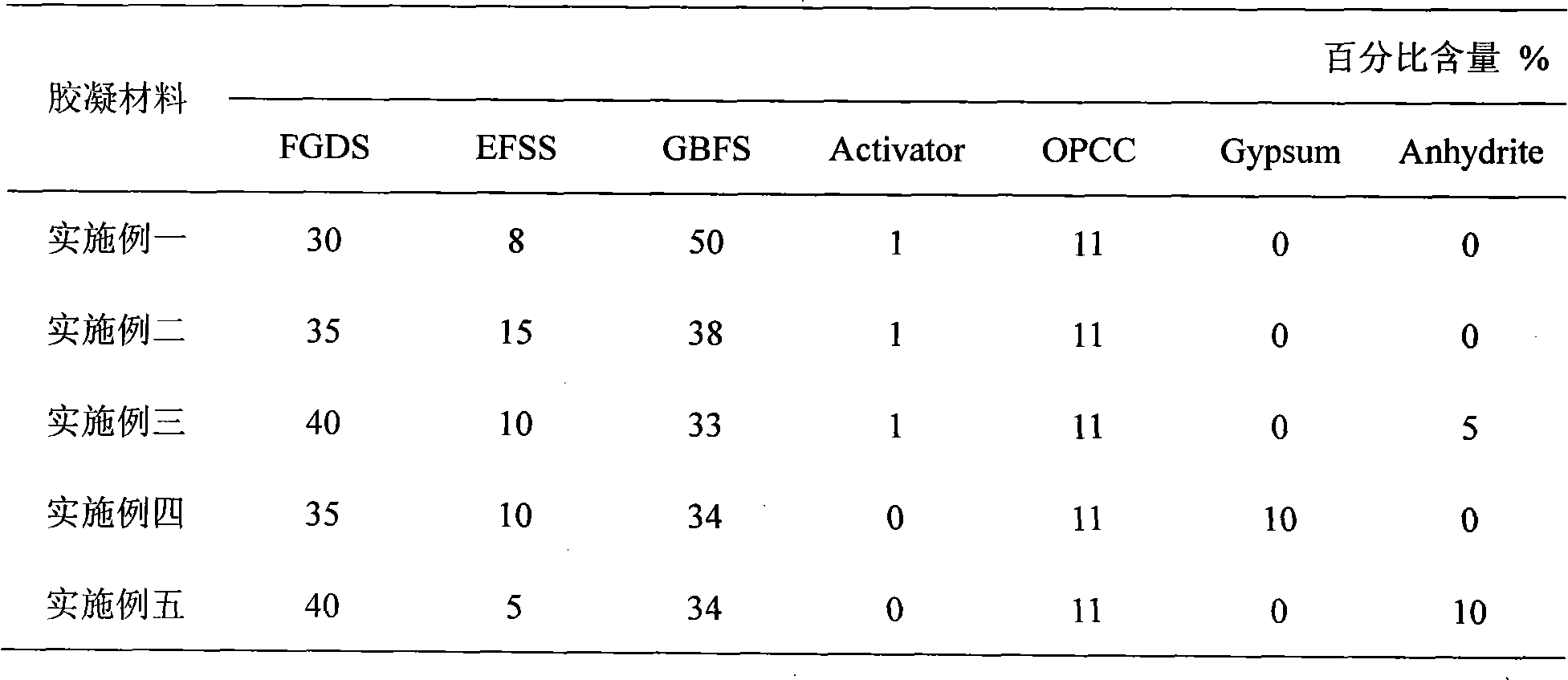

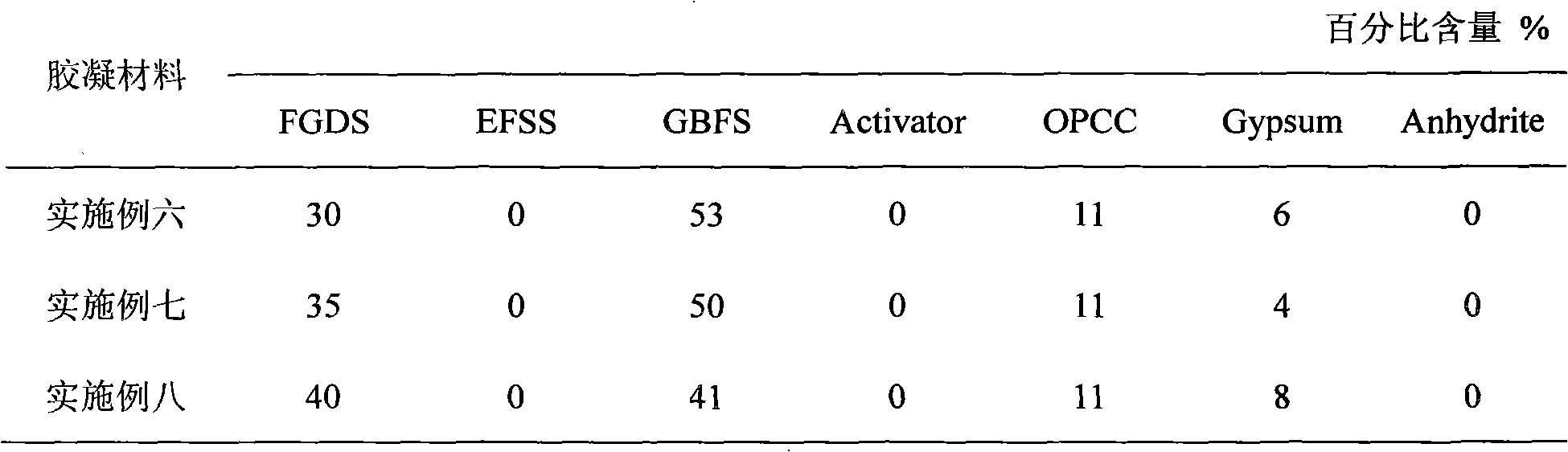

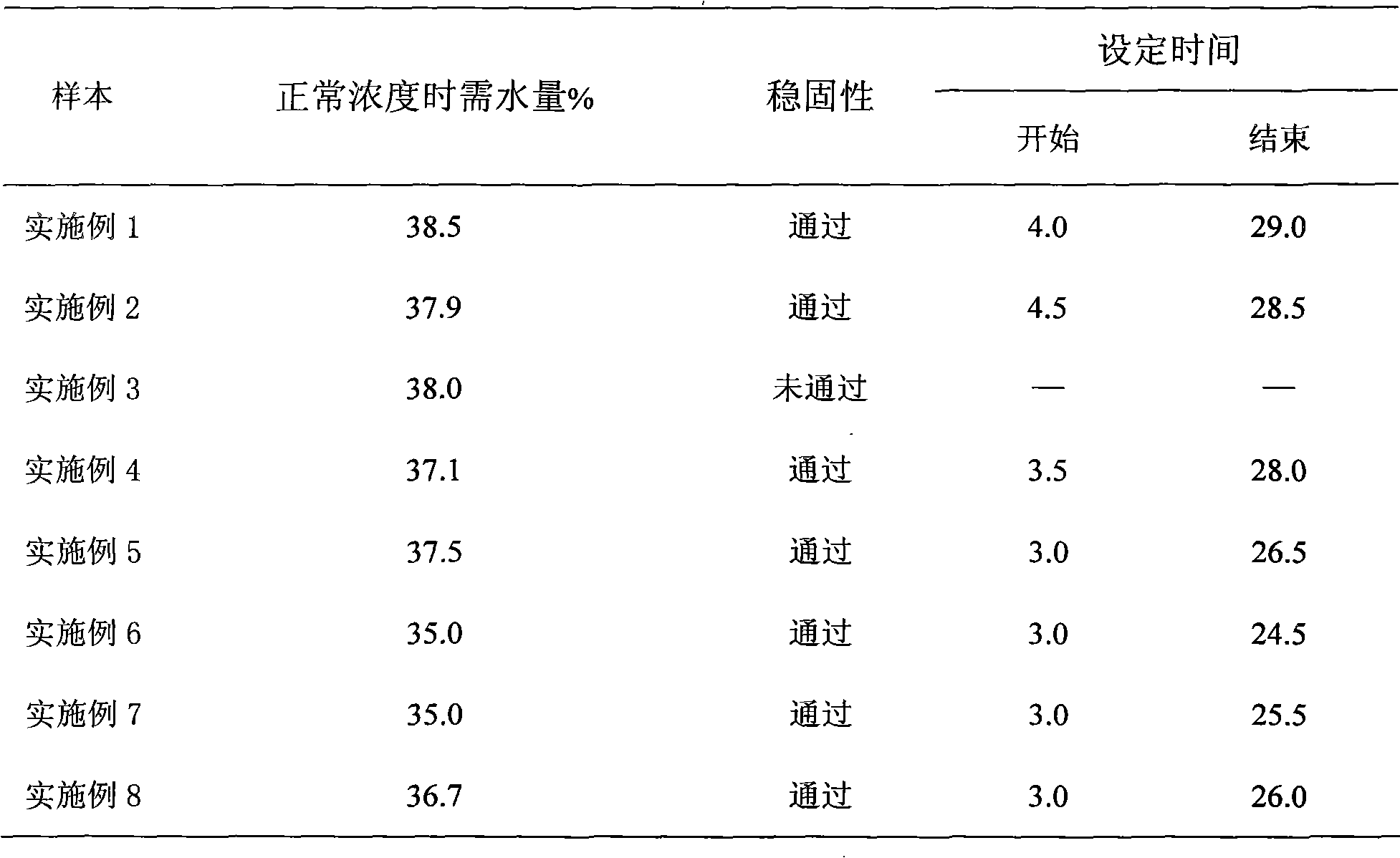

[0027] Place the FGDS and EFSS materials in a microwave oven at 105°C for one night and grind them with alumina in a ceramic ball mill to make the surface area reach 350M 2 / KG, grind samples such as cement slag, lime, slag powder, blast furnace slag and put the additives required for the reaction into the ball mill to make the final product. It varies according to the composition, and its composition is shown in Table 1.

Embodiment 2

[0029] The components were added and mixed as described in Table 1, and the rest were the same as in Example 1.

Embodiment 3

[0031] The components were added and mixed as described in Table 1, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Water permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com