Method for manufacturing micro-nano fluid control system by using low-pressure bonding technology

A production method, micro-nano technology, applied in the field of micro-nano fluid system production, can solve problems such as excessive bonding temperature and pressure, deformation of microfluidic pipelines, and damage to microstructure patterns, etc., to achieve easy channel blockage, good flexibility, and uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

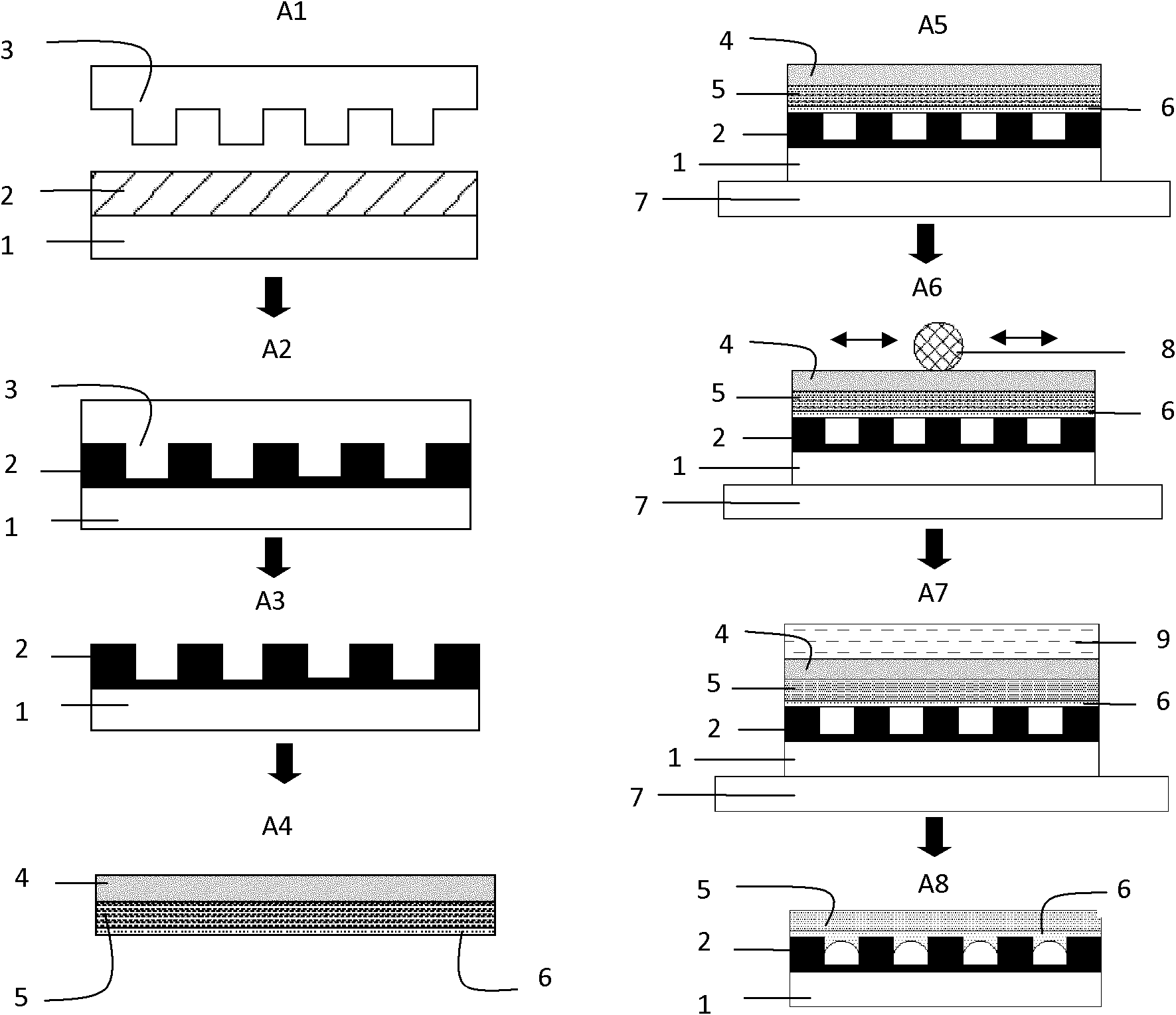

[0027] The specific implementation process is shown in Figure 1, wherein Figure 1 (A1) is the preparation of the substrate and template; Figure 1 (A2) is the nanoimprint technology to replicate the grating pattern; Figure 1 (A3) is to remove the imprint template; Figure 1 (A4) is the double-layer SU-8 structure of the PET substrate; Figure 1 (A5) is the preparation for bonding; Figure 1 (A6) is the roller so that the bonding layer is in full contact with the grating structure layer; Figure 1 (A7) is placed on the heavy Heating on the physical heating platform to complete the bonding; drying after exposure in Figure 1 (A8), separating the PET substrate, and completing the channel fabrication.

[0028] In this embodiment, the low-pressure bonding technology is used to manufacture the micro-nano fluidic system according to the following steps:

[0029] 1. Take the glass sheet as the base, wash it with water and acetone, put it in an oven, and bake it at 130°C for 20 minutes to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spin coating thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com