High-efficiency pre-separation pulse bag-type dust collector

A technology of pulse cloth bag and dust collector, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of insufficient mixing of alumina particles and flue gas, short service life of filter bags, uneven airflow distribution, etc. The effect of increasing the effective use area, prolonging the service life and reducing the load of the filter bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

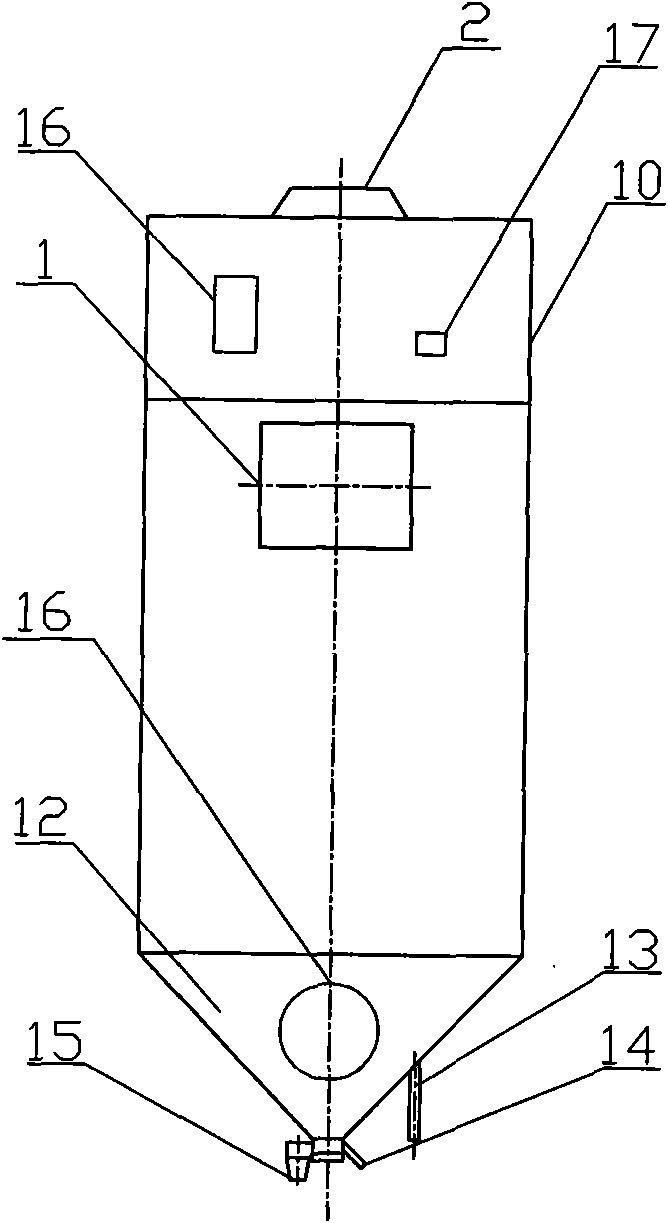

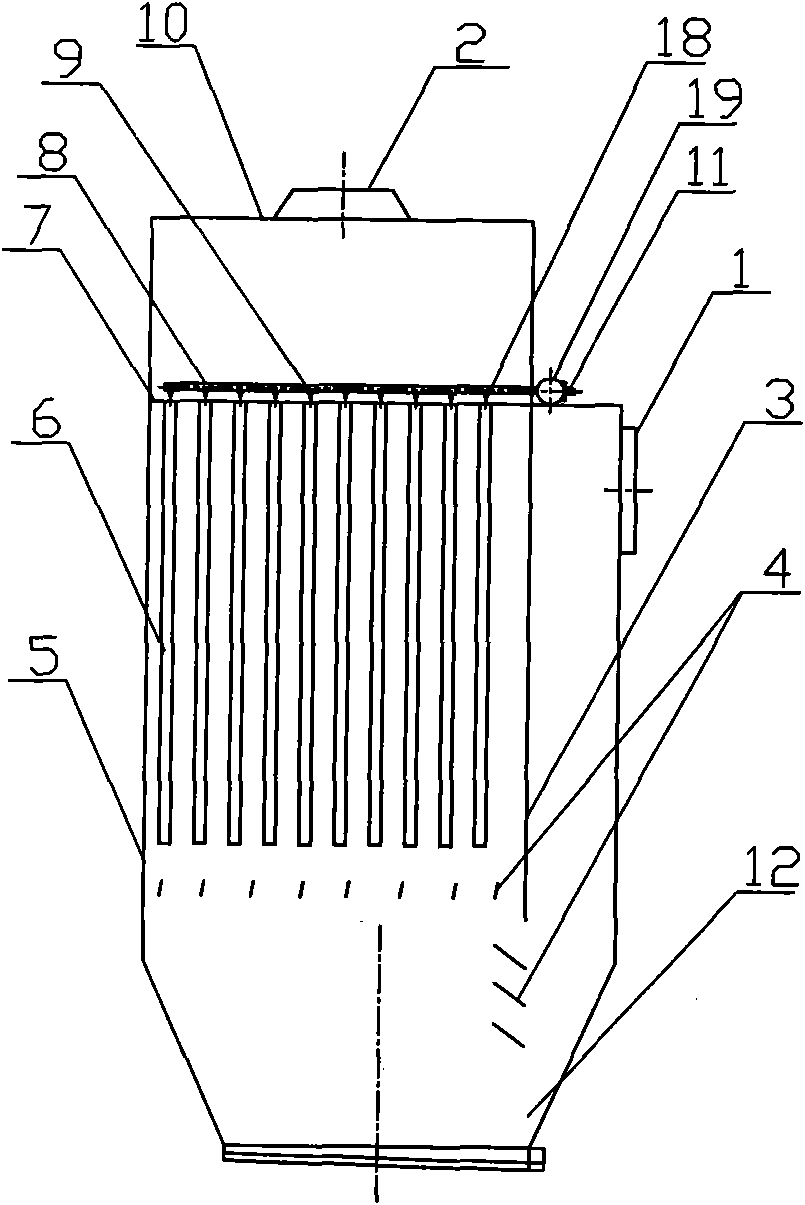

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the schematic diagrams.

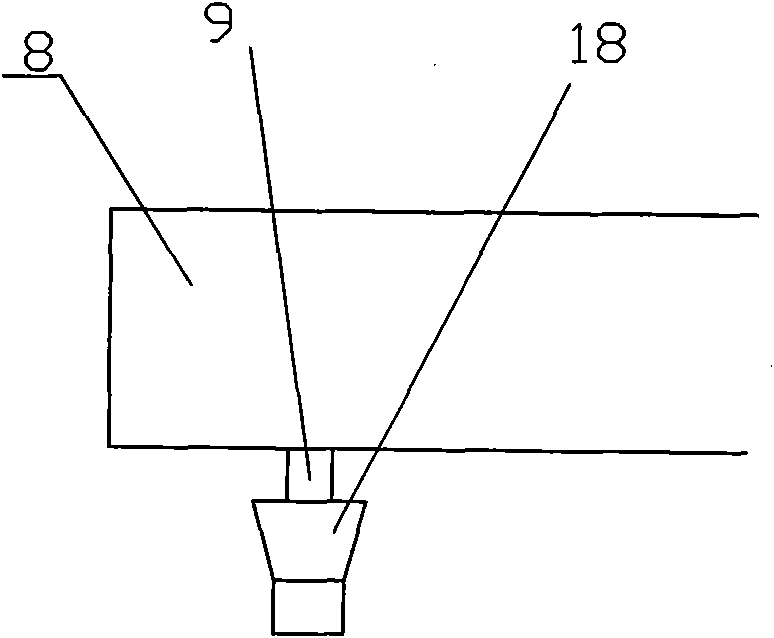

[0025] Such as figure 1 and figure 2 As shown, the high-efficiency pre-separation pulse bag filter of the present invention includes an upper box body 10, a middle box body 5, a dust collector air outlet 2 arranged at the upper box body 10, and a dust collector air inlet 1 arranged at the middle box body 5 In the middle box body 1, there are blowing pipe 8, nozzle 9, frame 6 and cloth bag. Board 3 and frame 6 are provided with cloth bags, the bottom of isolation plate 3 is provided with deflector 4 , the bottom of frame 6 is provided with deflector 4 , and frame 6 is arranged in sections of 2-10 sections, isolation plate 3 and frame 6 The deflector plate below is one or more stages, the height of the frame 6 is lower than the height of the isolation plate 3, the frame 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com