Pressurized water reactor nuclear power plant mega-kilowatt unit complete low neutron escape advanced one-quarter refueling method and safety analysis system thereof

A pressurized water reactor nuclear power plant, safety analysis technology, applied in the field of improvement of nuclear reactor core refueling method and nuclear reactor safety analysis system, can solve the problems of low fuel utilization rate, high neutron leakage rate, etc., to improve safety and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

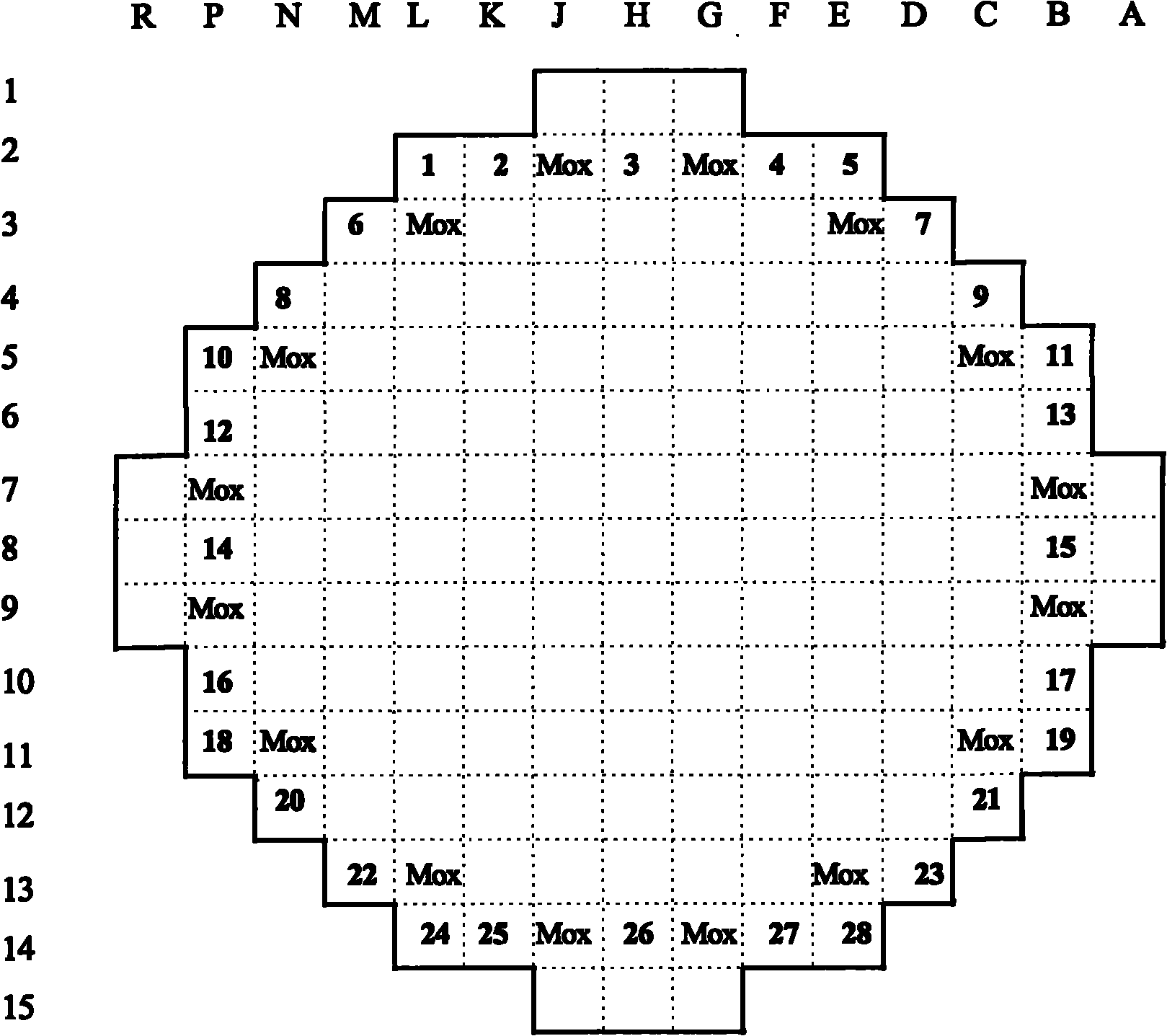

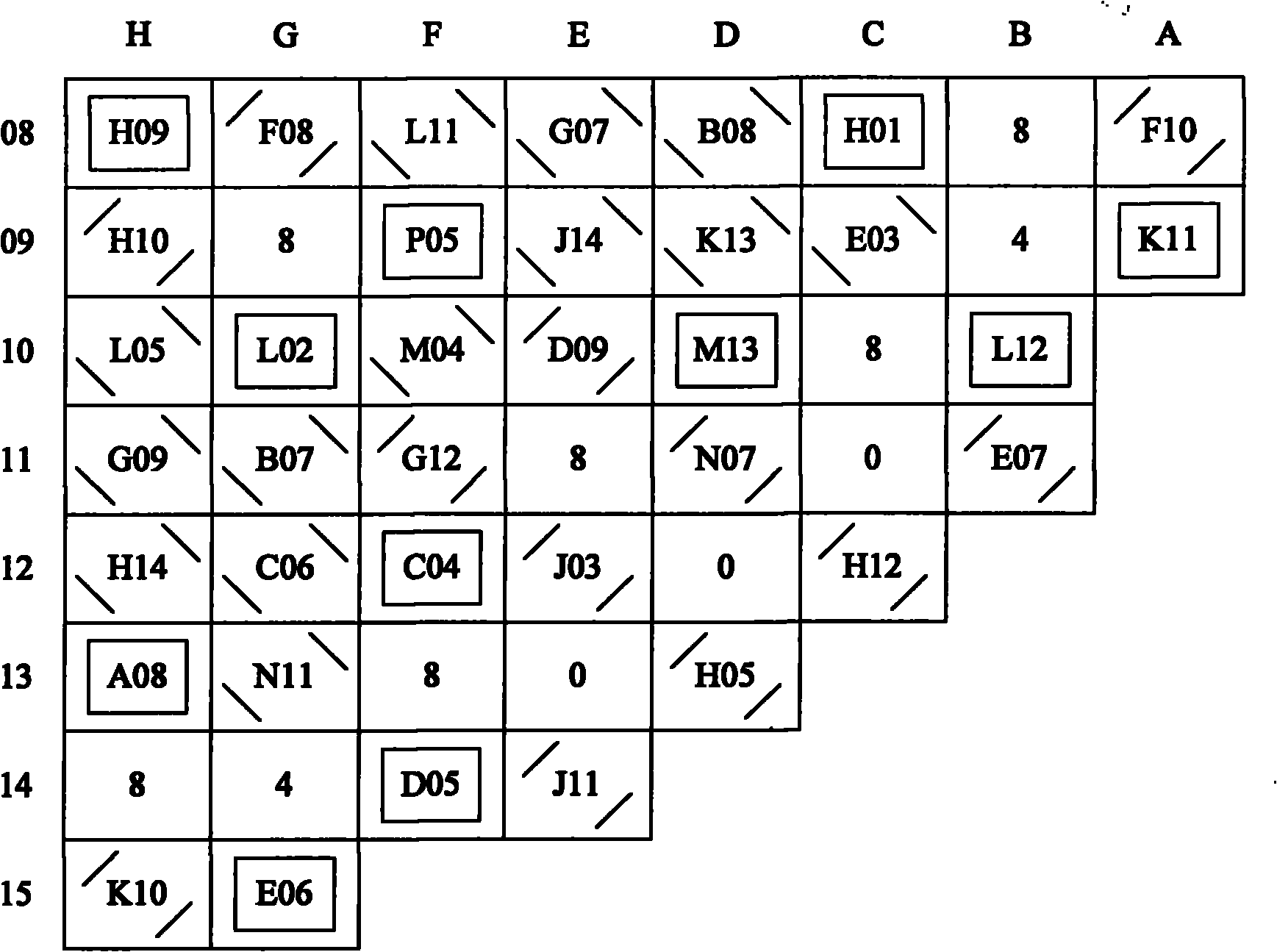

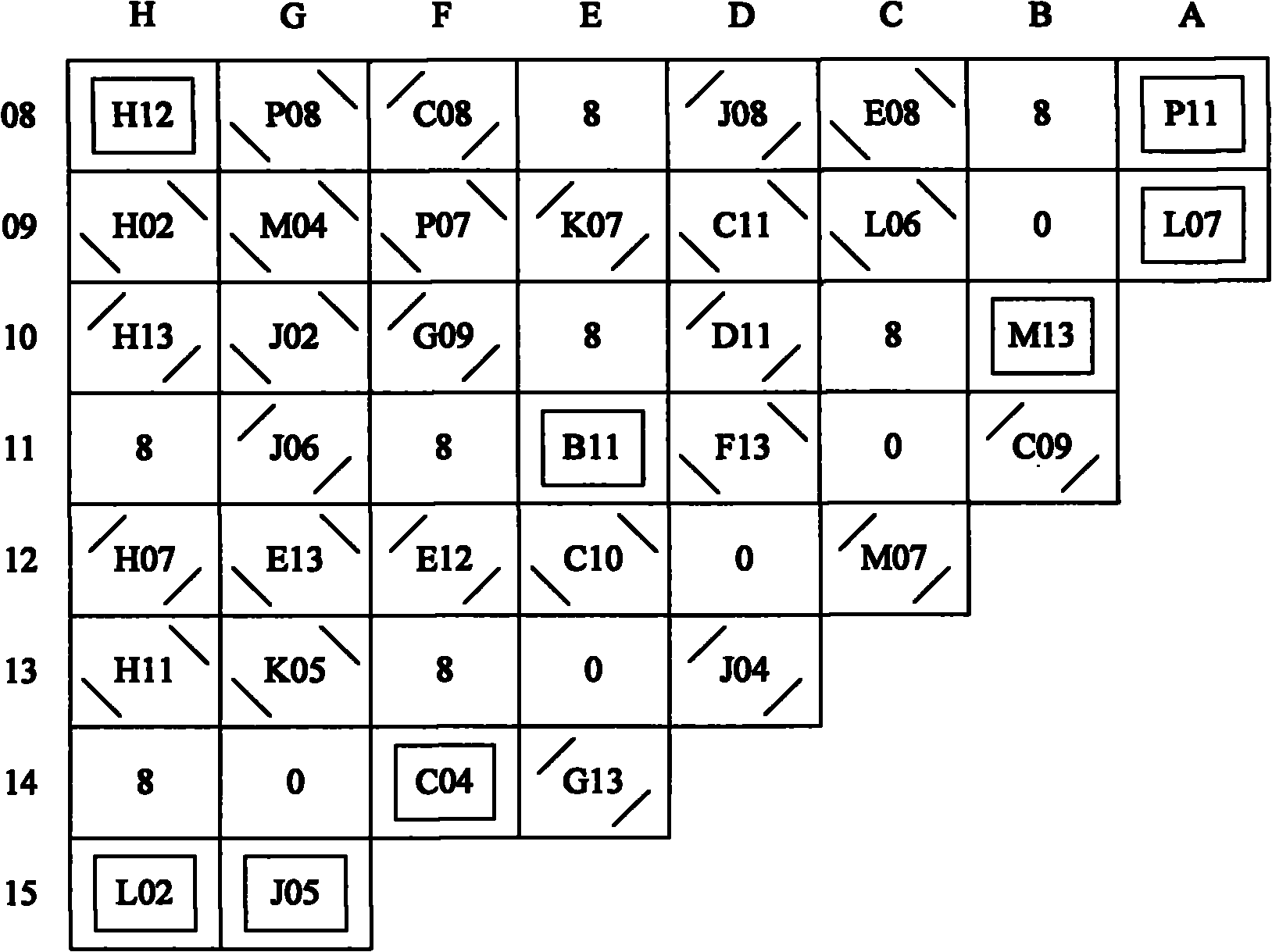

[0053] The schematic diagram of the partial layout of the core for the complete low neutron leakage 1 / 4 refueling in the first embodiment is as follows figure 2 As shown, it is 1 / 4 of the overall layout schematic diagram, in which there are 40 groups of new fuel assemblies with an enrichment degree of 4.2%. figure 2 in, symbol Indicates a new fuel assembly with an enrichment degree of 4.2%, a total of 40 groups; Indicates that the enrichment degree is 4.2% of the second cycle of refueling components, a total of 40 groups; Indicates that the enrichment degree is 4.2% of the third cycle of refueling components, a total of 40 groups; Represents the fourth cycle of refueling components with an enrichment degree of 4.2%, and there are 37 groups in total.

[0054] Its markings H09, F08, etc. are the position codes for recording the source of components when unloading, which can be changed according to different loading schemes. The assembly positions marked 0, 4, and 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com