Method for manufacturing raised grating alignment mark in imprinting lithography

A technology for alignment marks and manufacturing methods, which is applied in microlithography exposure equipment, photoplate making process of pattern surface, optics, etc., can solve the problems of alignment image contrast drop, etc., to achieve improved accuracy, wide application range, and improved Effect of Imprint Alignment Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

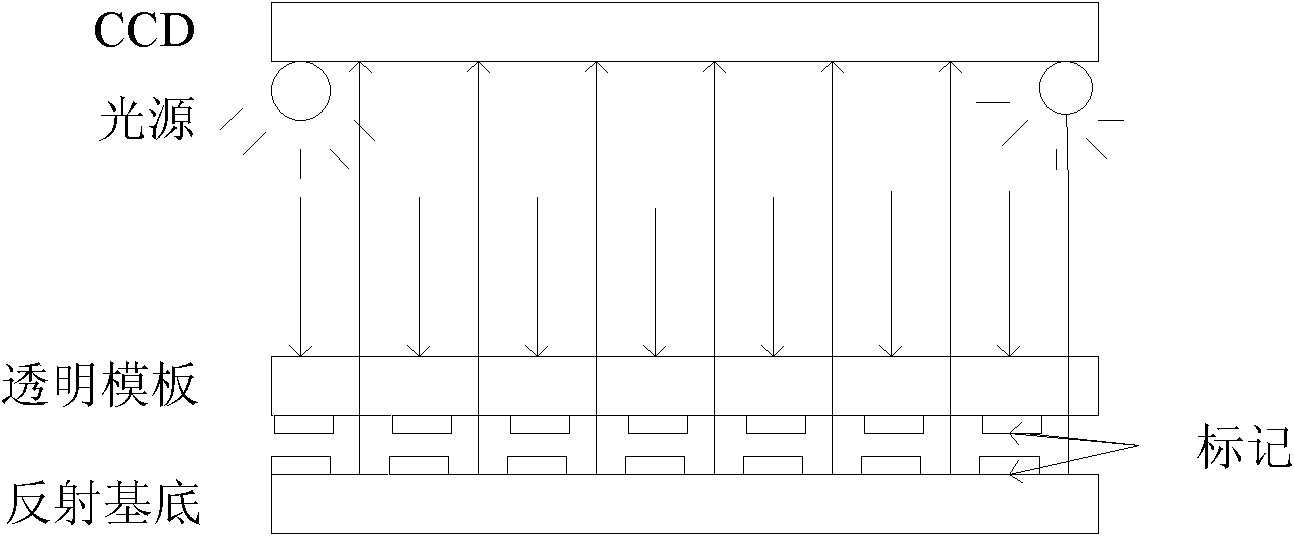

[0042] The manufacturing method of the raised grating alignment mark in the imprint lithography of the present invention specifically comprises the following steps:

[0043] (1) grating material selection:

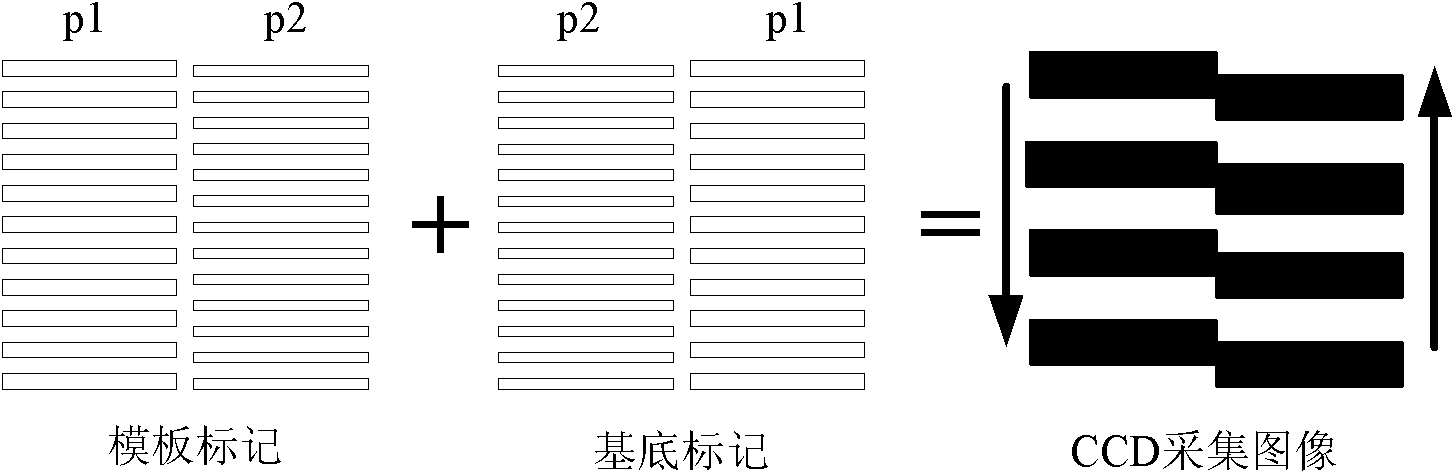

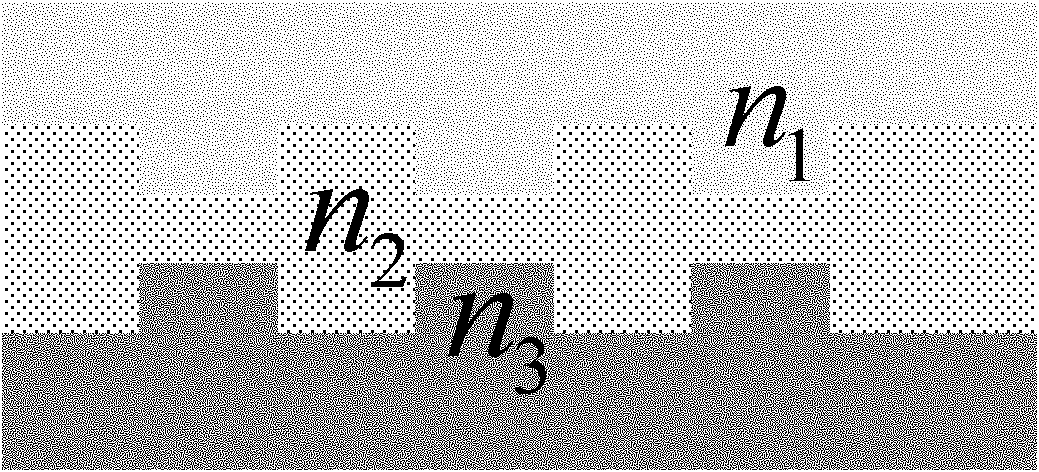

[0044] Based on the imprint lithography alignment of Moiré fringe phase matching, through the Fresnel interface theorem and time-domain finite difference calculation, the relationship between the contrast of the Moiré fringe image and the refractive index of the grating material is analyzed to determine the correspondence between the high-contrast Moiré fringe image The refractive index range of the refraction grating, and select the grating marking material within this range. In imprinting, under the condition that the substrate is Si and the template is glass, the template grating material is a material with a refractive index of about 1.9, and the material used for the substrate is It is a material with a refractive index of about 2.7.

[0045] (2) Raised grating produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com