Rolling bearing taking carbon graphite or electrographite as integral holder and manufacturing method thereof

A technology of electrochemical graphite and rolling bearings, which is applied in the direction of rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of affecting the use environment of rolling bearings, limitations, and failure to work, and achieve the effect of good self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

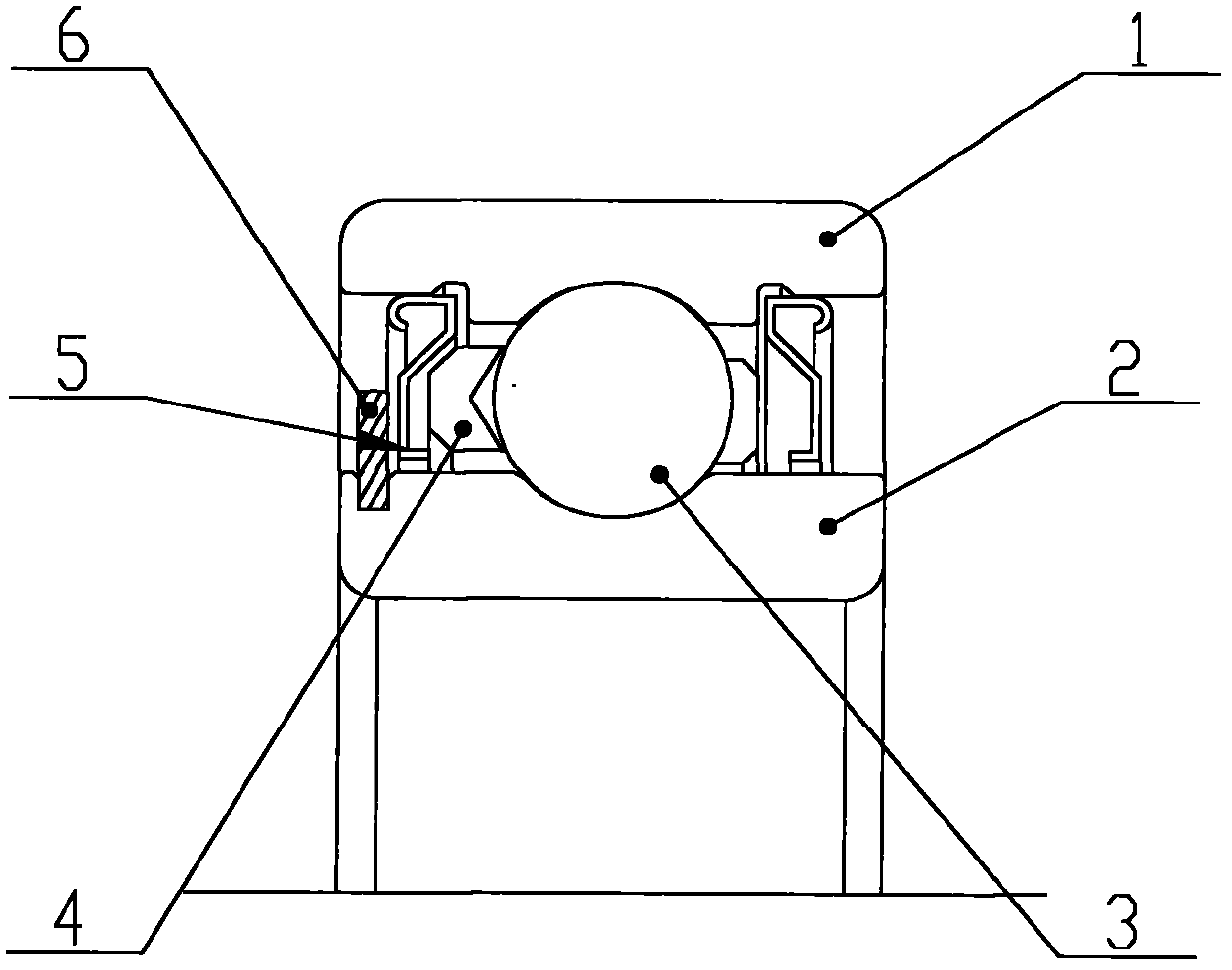

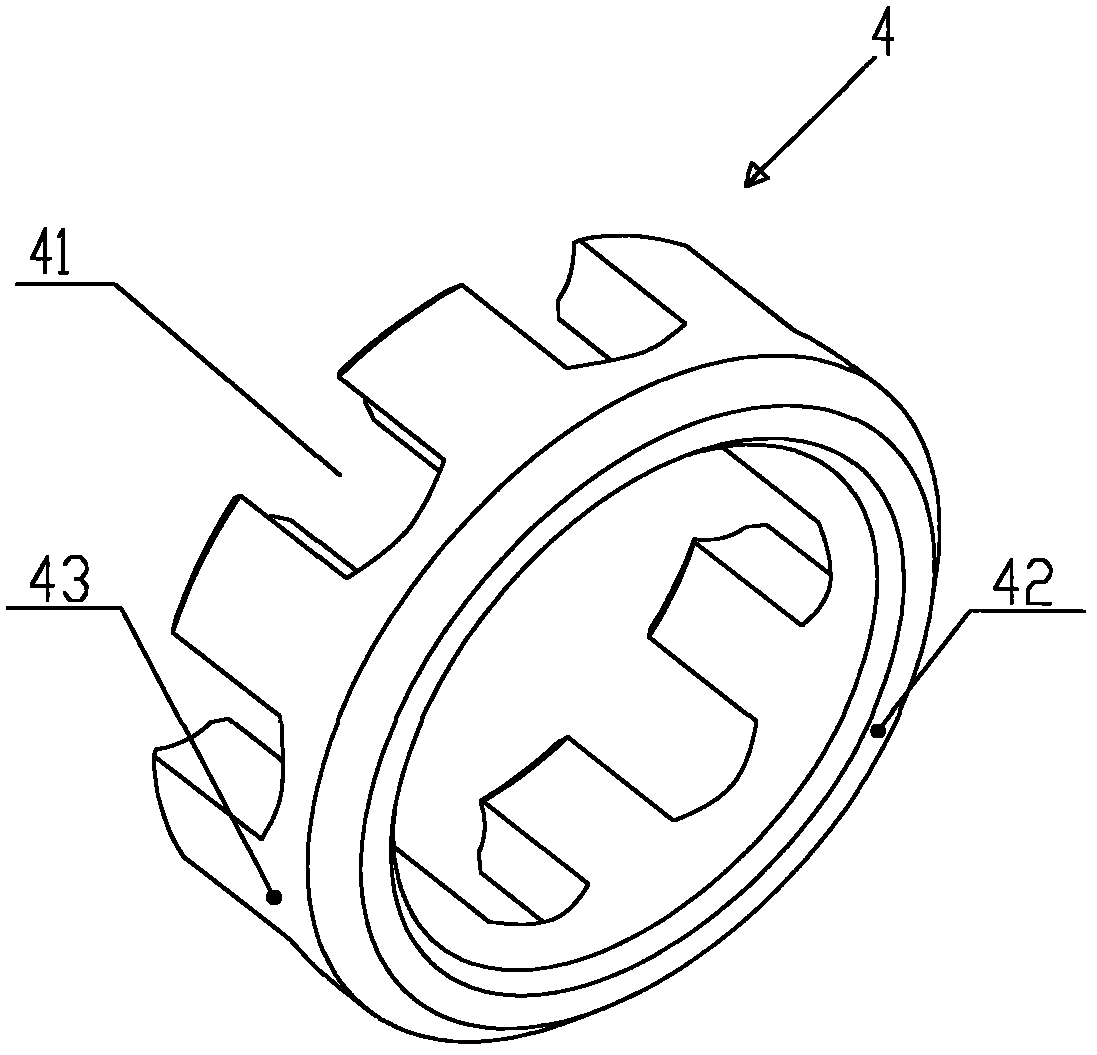

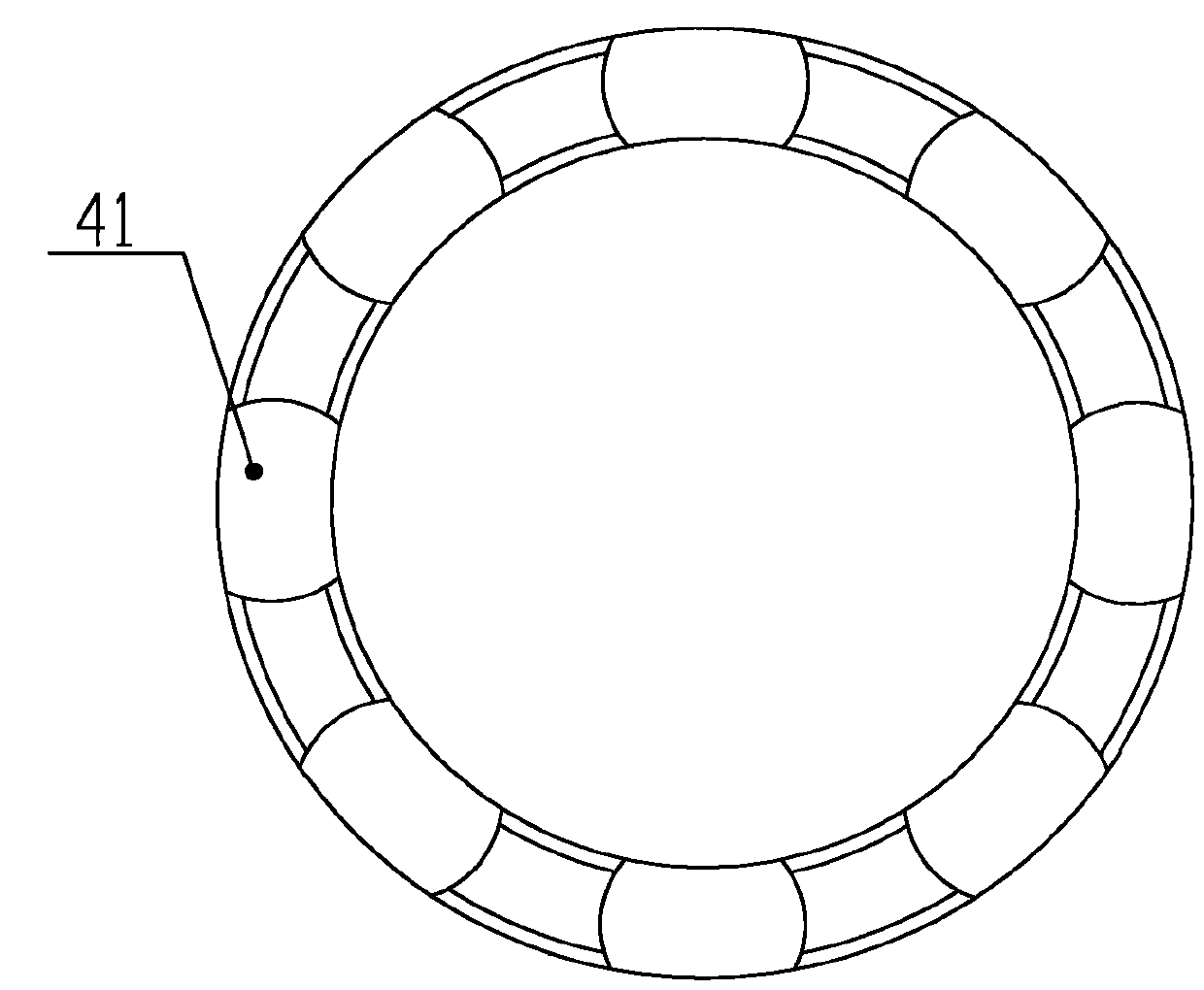

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Using corresponding raw materials and manufacturing processes, carbon graphite and electrochemical graphite can be produced. The applicant found that both carbon graphite and electrochemical graphite have excellent properties such as high temperature resistance, low temperature resistance, and corrosion resistance. The applicant applied carbon graphite and electrochemical graphite to rolling bearings to solve the technical problem of short plate effect of existing rolling bearing cages under high temperature, low temperature or strong corrosive medium. However, the current traditional high and low temperature resistant bearing cages are generally made of materials such as polytetrafluoroethylene (PTFE), soluble polytetrafluoroethylene (PFA) or polyetheretherketone (PEEK). Therefore, the pocket of the retainer can be made into a closed shape with the width of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com