Straddle forklift

A forklift and leg-inserting technology, applied in the direction of lifting devices, etc., can solve the problems of short service life, limited lifting speed and lifting capacity, low lifting capacity, etc., and achieve the effect of long service life, convenient maintenance and stable unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

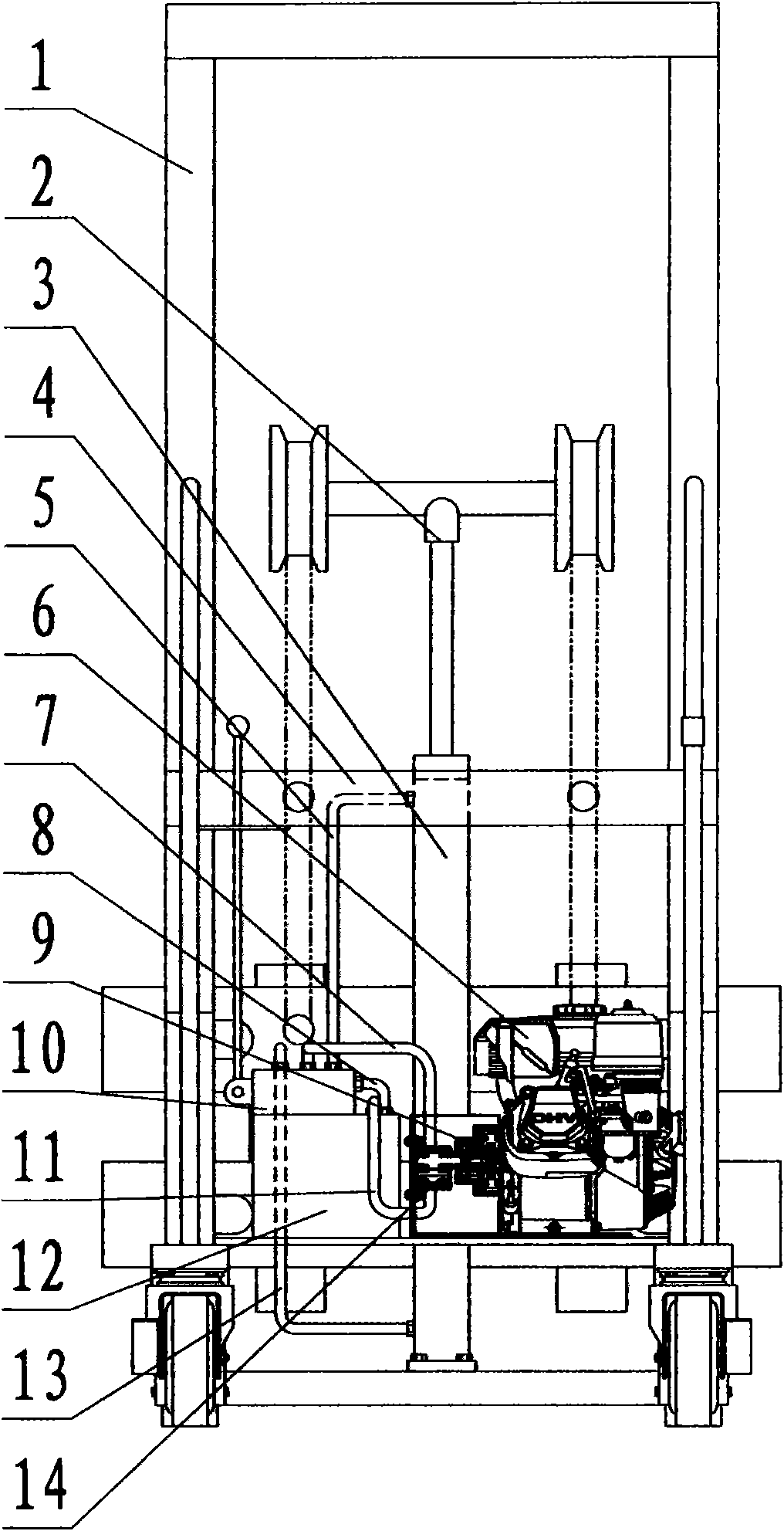

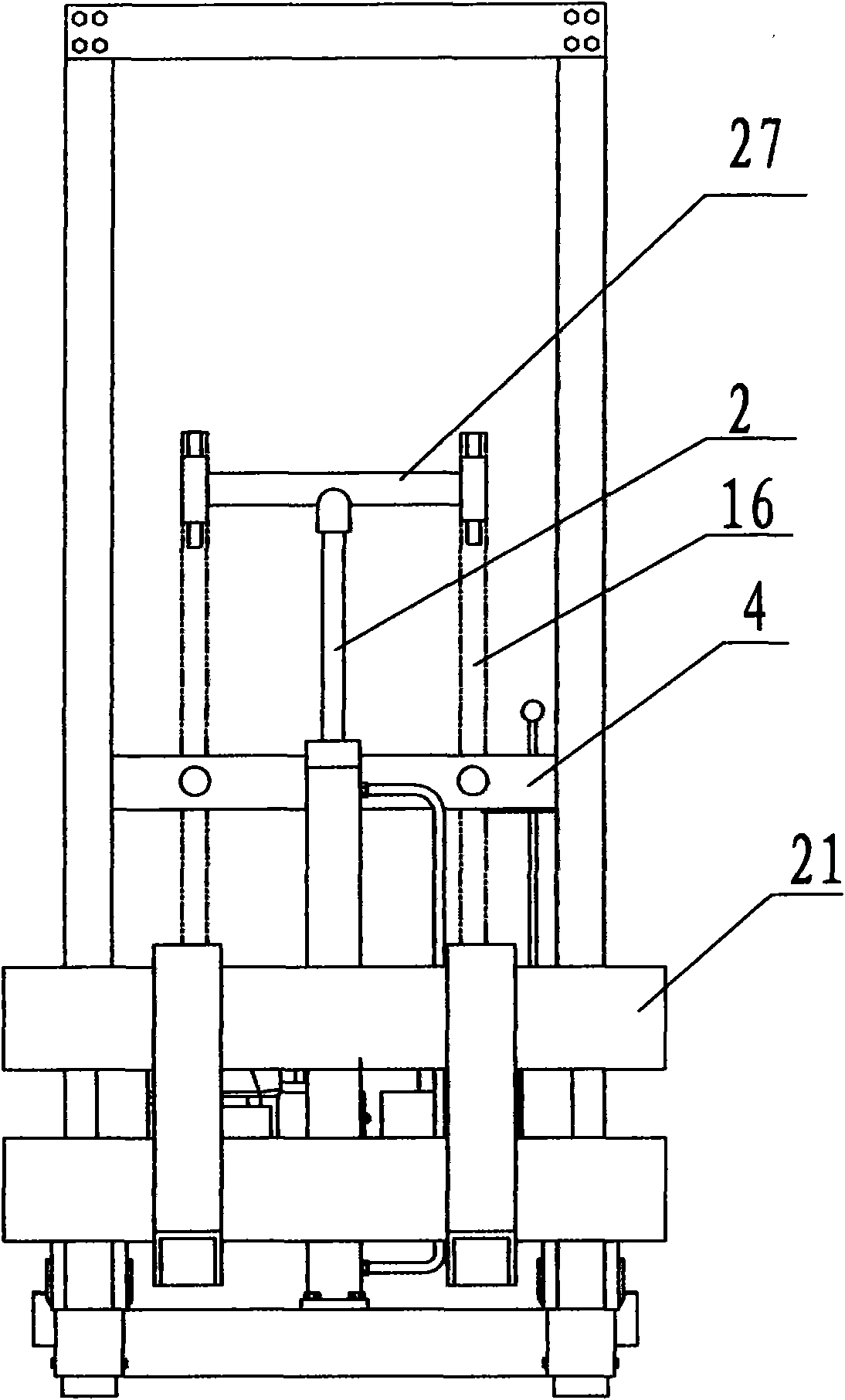

[0024] Such as Figure 1 to Figure 3 As shown, the forklift truck of the present invention includes a lifting and unloading device and a driving device, the driving device includes an engine 6 and a hydraulic transmission device, and the hydraulic transmission device includes a hydraulic pump 14, a hydraulic oil tank 12, a reversing valve 10 and a hydraulic cylinder 3 , wherein the hydraulic oil tank 12, the hydraulic pump 14, the reversing valve 10 and the hydraulic cylinder 9 are connected through hydraulic pipelines. The output shaft of the engine 6 is connected with the input shaft of the hydraulic pump 14 to drive the hydraulic pump 14. The hydraulic cylinder 14 has a push rod 2 that can stretch out from the hydraulic cylinder 3 and stretch up and down. The push rod 2 is connected with the lifting and unloading device .

[0025] The lifting and unloading device includes a chassis 26, a fork 20, a mast 1, a fork frame 21 and a transmission chain assembly. The mast 1 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com