Composite solid acid catalyst and preparation method thereof

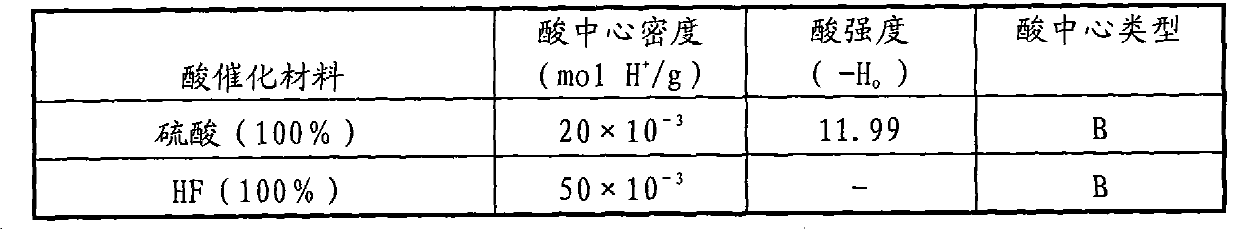

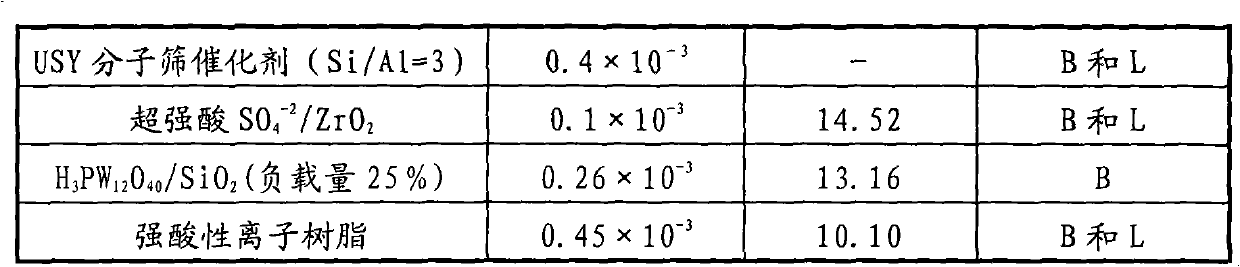

A composite solid acid and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems that cannot reach the order of magnitude of liquid acid, achieve catalytic activity and selectivity, and high catalytic performance Activity and selectivity, effect of uniform acid strength distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Weigh 22.81 grams of phosphotungstic acid (H 3 PW 12 o 40 .21H 2 O) Dissolve in 135.0ml deionized water to make phosphotungstic acid solution. 60.3 grams of 20-40 mesh SiO 2 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 75°C for 1.0 hour, cool down to room temperature, add the prepared phosphotungstic acid solution under the condition of maintaining vacuum, soak for 1.5 hours, and then put it in a drying box for 60 °C for 3 hours to obtain 25% by weight H 3 PW 12 o 40 And 75% heavy silica gel supported heteropolyacid material, denoted as 25%HPW / SiO 2 .

[0052] Weigh out 2.85 g of C S2 CO 3 Dissolved in 120.0ml of ionized water, dubbed C S2 CO 3 aqueous solution. The above 25%HPW / SiO 2 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 55°C for 1.0 hour, cool down to room temperature, and add the prepared C under the condition of maintaining vacuum S2 CO 3 solution, the reaction proceeds according to formula (1)...

Embodiment 2

[0058] Weigh 25.4 grams of phosphotungstic acid (H 3 PW 12 o 40 .21H 2 O) dissolved in 150.0ml deionized water, dubbed H 3 PWO 40 solution. 67.1 grams of 20-40 mesh SiO 2 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 75°C for 1.0 hour, cool down to room temperature, and add the prepared H 3 PW 12 o 40 solution, impregnated for 1.5 hours, and then dried in a drying oven at 60°C for 3 hours to obtain a solution containing 25% by weight H 3 PW 12 o 40 And 75% heavy silica gel supported heteropolyacid material, denoted as 25%HPW / SiO 2 .

[0059] Weigh out 1.61 g of K 2 CO 3 Dissolve in 145.0ml ionized water and make K 2 CO 3 aqueous solution. The above 25%HPW / SiO 2 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 55°C for 1.0 hour, cool down to room temperature, and add the prepared K under the condition of maintaining vacuum 2 CO 3 solution, the reaction proceeds according to formula (1) (where M is K, x=3.0). Imme...

Embodiment 3

[0063] Weigh 17.1 grams of phosphomolybdic acid (H 3 PMo 12 o 40 .17H 2 O) dissolved in 100.0ml deionized water, dubbed H 3 PWO 40 solution. 44.0 grams of 20-40 mesh Al 2 o 3 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 75°C for 1.0 hour, cool down to room temperature, and add the prepared H 3PW 12 o 40 solution, impregnated for 1.5 hours, and then dried in a drying oven at 60°C for 2.0 hours to obtain a solution containing 25% by weight H 3 PMo 12 o 40 And 75% heavy alumina loaded heteropolyacid, denoted as 25% HPMo / Al 2 o 3 .

[0064] Weigh out 3.26 g of C S2 CO 3 Dissolve in 97.0ml ionized water, make C S2 CO 3 aqueous solution. The above 25% HPMo / SiO 2 Put it into a suction filter bottle, treat it at 0.095 MPa vacuum and 55°C for 1.0 hour, cool down to room temperature, and add the prepared C under the condition of maintaining vacuum S2 CO 3 solution, the reaction proceeds according to formula (2) (where M is Cs, x=2.5).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com