Squid ring cutting machine

A ring cutting machine and squid technology, applied in metal processing, application, food preparation, etc., can solve the problem of low production efficiency, and achieve the effect of improving processing productivity, high material density, and high moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] Detailed ways The present invention will be further described below in conjunction with the embodiments.

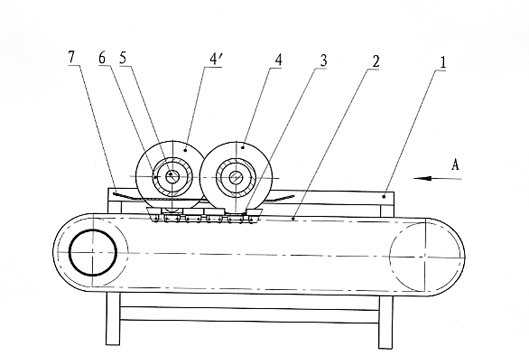

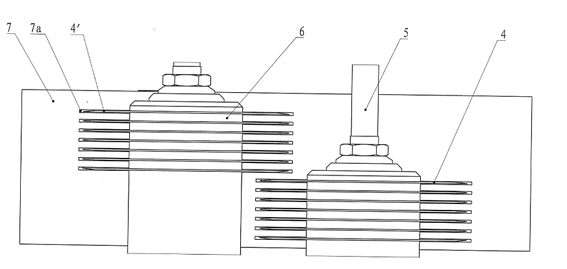

[0015] 1. A squid ring cutter, such as figure 1 , 2 As shown in , 3 and 4, the frame 1 is a four-legged rectangular frame structure, and a chain conveyor belt 2 is passed through the middle of the frame. 3. A frozen squid tube placement slot 3a and a knife slot 3b are arranged on the material base. The material seat is a cuboid, and the squid tube placement slot is an arc-shaped bottom long slot with an axis parallel to the length of the cuboid. The slits are perpendicular to the axis of the long slit and are arranged at equal intervals. The slits are actually pierced at both ends. Through the thin grooves on both sides of the material base, the bottom of the knife slot is lower than the bottom of the placement groove. The material seat and the chain plate are integrated, and its width is the width of the chain plate, that is, the squid tube placement slot on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com