Vertical magnetic recording medium, vertical magnetic recording medium manufacturing method, and magnetic recording/reproduction device

A technology of perpendicular magnetic recording and manufacturing method, which is applied in magnetic recording, data recording, disc carrier manufacturing, etc., and can solve problems such as insufficient impact resistance of the protective film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

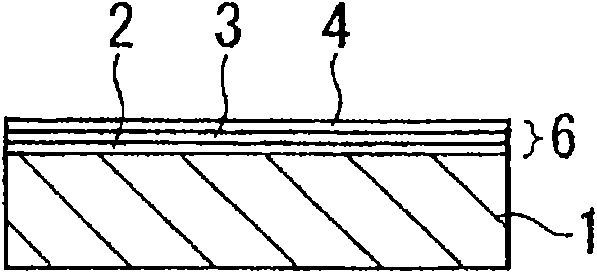

[0140] The perpendicular magnetic recording medium A shown in FIG. 1(I) was produced by the production method shown below.

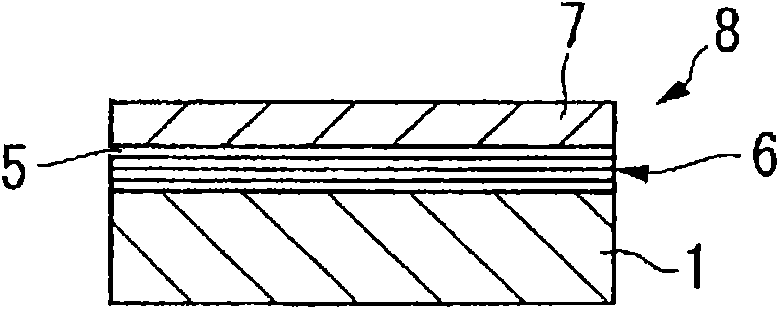

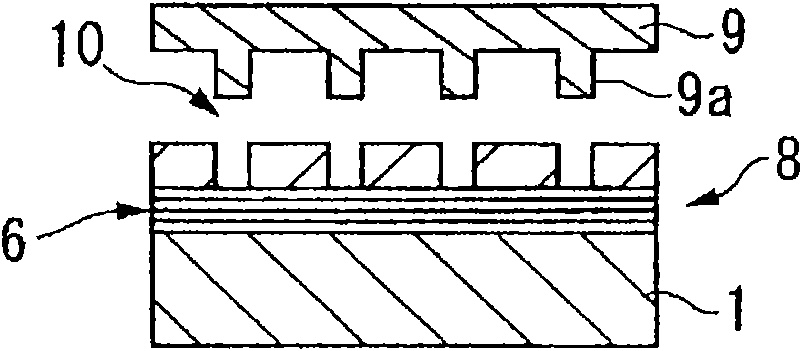

[0141] First, as the non-magnetic substrate 1, prepare a cleaned disc-shaped glass substrate for HD (manufactured by Ohara Co., Ltd., 0.85 inches in outer diameter), and set it in a vacuum exhausted to 1.0×10. -5 Vacuum chamber below pa. Then, on the nonmagnetic substrate 1, 65Fe-25Co-10B (atomic %) 50nm, Ru 0.8nm, and 65Fe-25Co-10B (atomic %) 50nm were sequentially formed without heating, thereby forming a soft magnetic backing layer 2. Next, an orientation control layer 3 made of Ru and having a thickness of 20 nm was formed on the soft magnetic backing layer 2 . By forming the 65Co-10Cr-15Pc-10SiO on the above-mentioned orientation control layer 3 2 (atomic %) magnetic layer 4 with a thickness of 12 nm forms the recording layer 6 . The magnetic layer 4 has magnetic material particles containing Co, Cr and Pt dispersed in SiO 2 granular structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com