A method for position-calibration of a digging assembly for electric mining shovels

A technology of components and motors, applied in the direction of using optical devices, mechanically driven excavators/dredgers, measuring devices, etc., can solve problems such as unsuitable and laborious production environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Such as figure 1 As shown, a fundamental characteristic in the operation of mining shovels and other similar excavators is that the motion of the bucket in the sagittal plane of the machine is generally independent of the rocking motion about the excavator's swing axis.

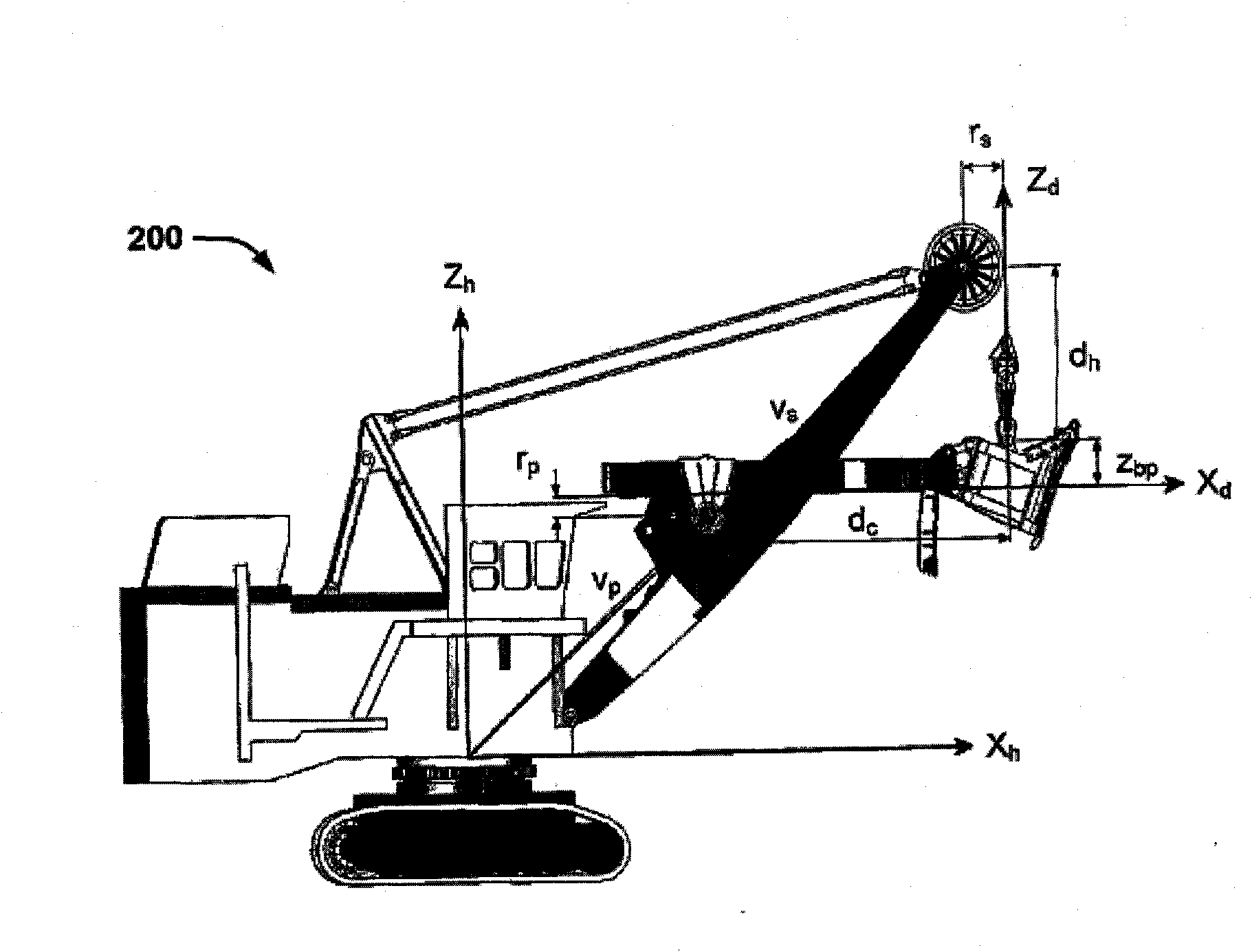

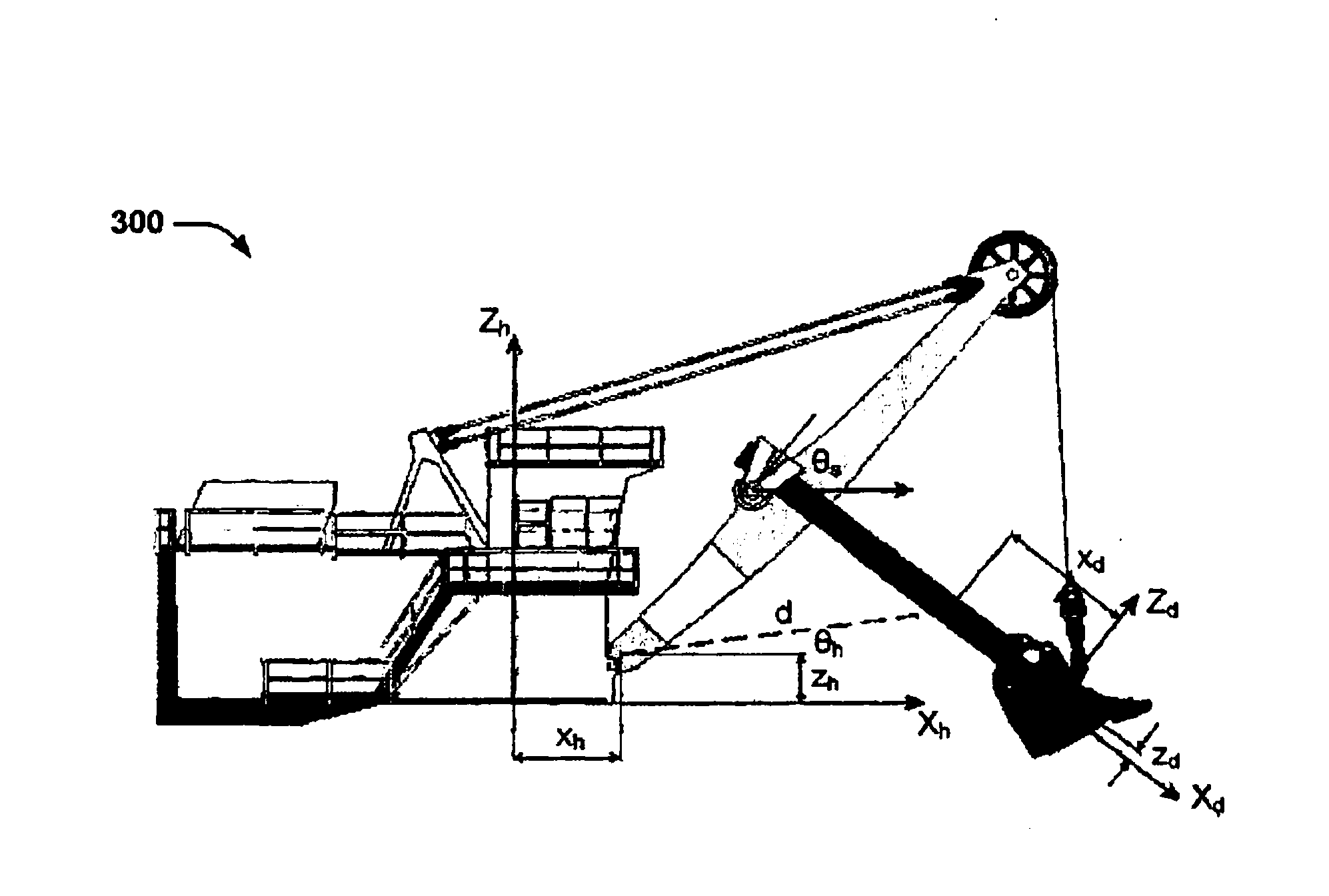

[0034] exist figure 2 and image 3 Definitions of geometric variables relevant to the discussion of the preferred embodiment are shown in .

[0035] Preferred embodiments are described in terms of:

[0036] • Specify a set of Cartesian coordinate axes fixed to the machine housing, where the (X,Z) plane lies in the sagittal plane of the machine housing and the Y axis is orthogonal. The Cartesian space defined by these axes is called h-space.

[0037] The identification point p in h space h =(x h ,z h ), which is used as the origin of the distance measuring sensor.

[0038] ● by angle θ h represented by (X in h space h ,Z h ) plane originating from p h The orientation line along which distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com