Zinc cathode active substance of zinc-nickel secondary battery and preparation method and application method thereof

A secondary battery and active material technology, applied to battery electrodes, alkaline battery electrodes, circuits, etc., to achieve the effects of weakening ohmic polarization, long cycle life, and inhibiting self-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

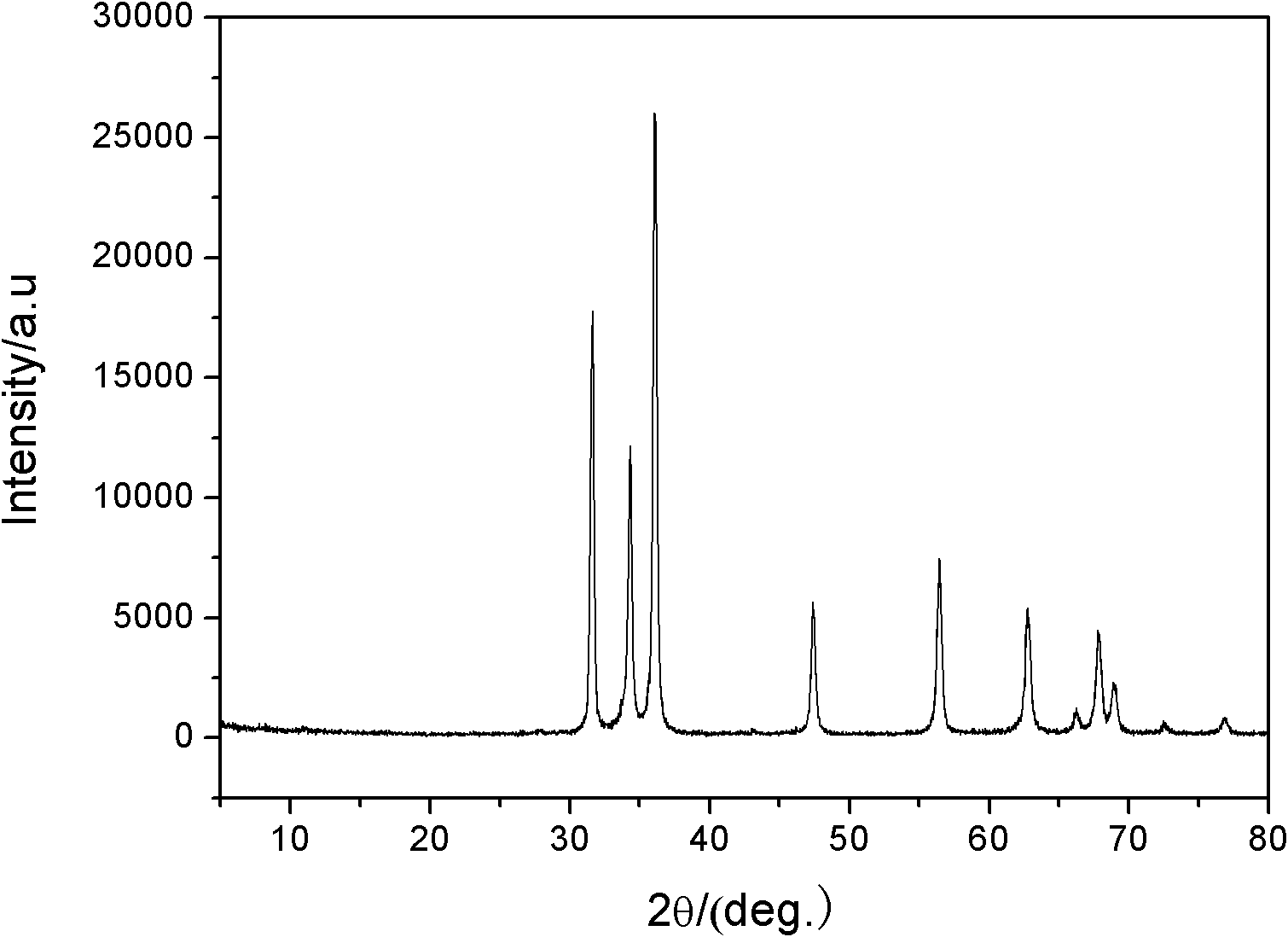

Image

Examples

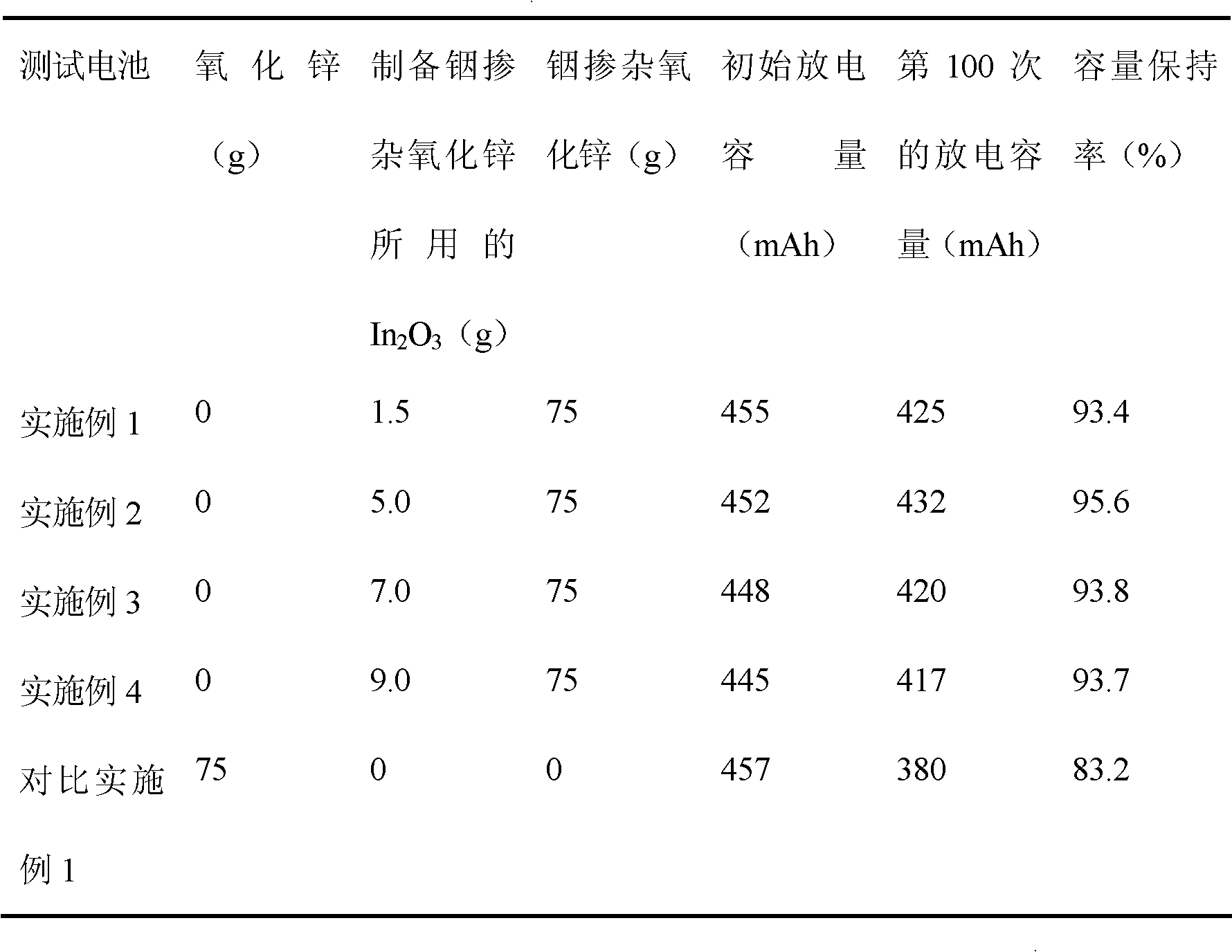

Embodiment 1

[0029] 1.5 parts by weight of analytically pure In 2 o 3 Be dissolved in the 12mol / L concentrated hydrochloric acid of 50 weight parts, the analytical pure ZnCl of 98 weight parts 2 Dissolve in 200 parts by weight of deionized water, and add 0.5 parts by weight of sodium dodecylbenzenesulfonate, fully mix the above two solutions and dilute 10 times with deionized water, then add ammonia water under strong mechanical stirring to adjust The pH of the solution is 7.0, continue to stir for 15 minutes, age for 1 hour, and ultrasonically disperse for 10 minutes, then transfer to a hydrothermal reaction kettle, put the reaction kettle in an oven at 180°C for 4 hours, and finally filter and wash the precipitate, and dry it at 60 Dry at ℃ for 4 hours, and calcined at 500℃ for 2 hours to obtain indium-doped zinc oxide. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 30g distilled water, place the beaker on an electric heating stirre...

Embodiment 2

[0031] 5 parts by weight of analytically pure In 2 o 3 Be dissolved in the 12mol / L concentrated hydrochloric acid of 50 weight parts, the analytical pure ZnCl of 94.5 weight parts 2 Dissolve in 200 parts by weight of deionized water, and add 0.5 parts by weight of sodium dodecylbenzenesulfonate, fully mix the above two solutions and dilute 10 times with deionized water, then add ammonia water under strong mechanical stirring to adjust The pH of the solution is 7.0, continue to stir for 15 minutes, age for 1 hour, and ultrasonically disperse for 10 minutes, then transfer to a hydrothermal reaction kettle, put the reaction kettle in an oven at 180°C for 4 hours, and finally filter and wash the precipitate, and dry it at 60 Dry at ℃ for 4 hours, and calcined at 500℃ for 2 hours to obtain indium-doped zinc oxide. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 30g distilled water, place the beaker on an electric heating stirre...

Embodiment 3

[0033] 7 parts by weight of analytically pure In 2 o 3 Be dissolved in the 12mol / L concentrated hydrochloric acid of 50 weight parts, the analytical pure ZnCl of 92.5 weight parts 2Dissolve in 200 parts by weight of deionized water, and add 0.5 parts by weight of sodium dodecylbenzenesulfonate, fully mix the above two solutions and dilute 10 times with deionized water, then add ammonia water under strong mechanical stirring to adjust The pH of the solution is 7.0, continue to stir for 15 minutes, age for 1 hour, and ultrasonically disperse for 10 minutes, then transfer to a hydrothermal reaction kettle, put the reaction kettle in an oven at 180°C for 4 hours, and finally filter and wash the precipitate, and dry it at 60 Dry at ℃ for 4 hours, and calcined at 500℃ for 2 hours to obtain indium-doped zinc oxide. Put 0.1g sodium dodecylbenzenesulfonate and 0.1g hexadecyltrimethylammonium bromide in a beaker, add 30g distilled water, place the beaker on an electric heating stirrer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com