Welding apparatus for solar module

A solar cell and welding device technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of different thermal expansion coefficients of aluminum paste coating and silicon layer, uneven distribution of local internal stress, lobes, etc., to prevent lobes, It is convenient to control the consistency of batch processing and reduce the effect of splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

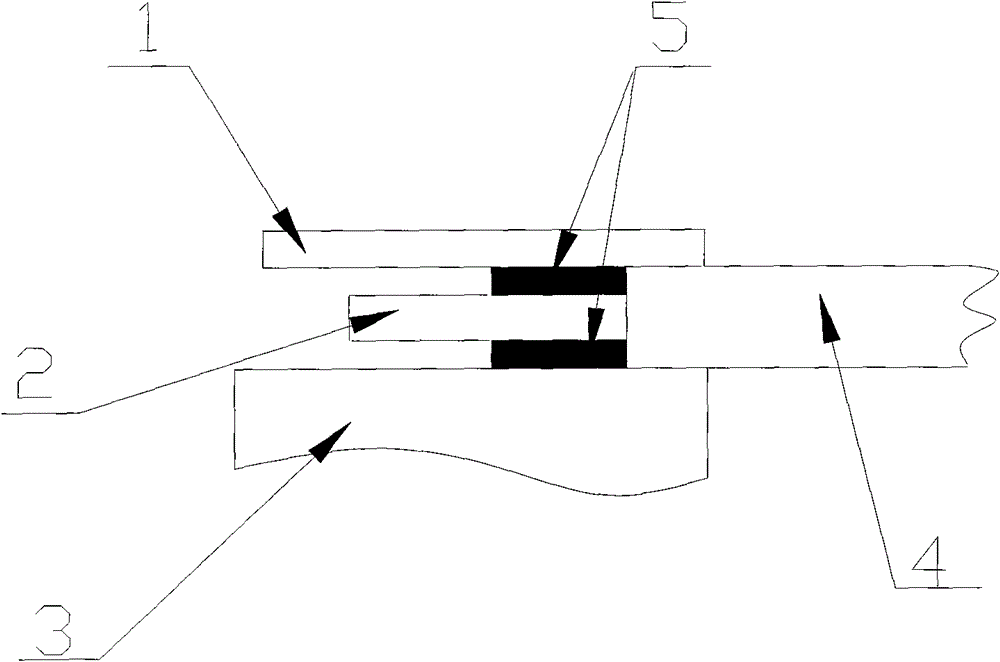

[0016] A welding device for a solar battery module, the device is mainly composed of a hot aluminum plate 3, a label backing paper 1, a panel 2, and a double-sided adhesive 5; Double-sided adhesive 5 is applied, and the label backing paper 1 and hot aluminum plate 3 sandwich the panel 2 coated with double-sided adhesive and the end of the battery sheet 4 close to the panel.

[0017] The hot aluminum plate 3 is welded with a heating template; the label backing paper 1 is neutral paper; the panel 2 is a high temperature resistant material. The panel 2 forms a positioning groove with the label backing paper 1 and the hot aluminum plate 3, and the battery piece 4 is placed in the positioning groove, which can be well positioned during welding and can leave a welding margin, effectively avoiding the battery piece that is easily caused by splits And the stress point of the hidden crack also acts as a buffer against the external force, preventing the external force from directly acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com