Method for preparing L-ornithine by utilizing enzyme method

An enzymatic preparation, ornithine technology, applied in the field of L-ornithine preparation, can solve the problems of complex process, difficult separation, high cost, and achieve the effects of short cycle, strong specificity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

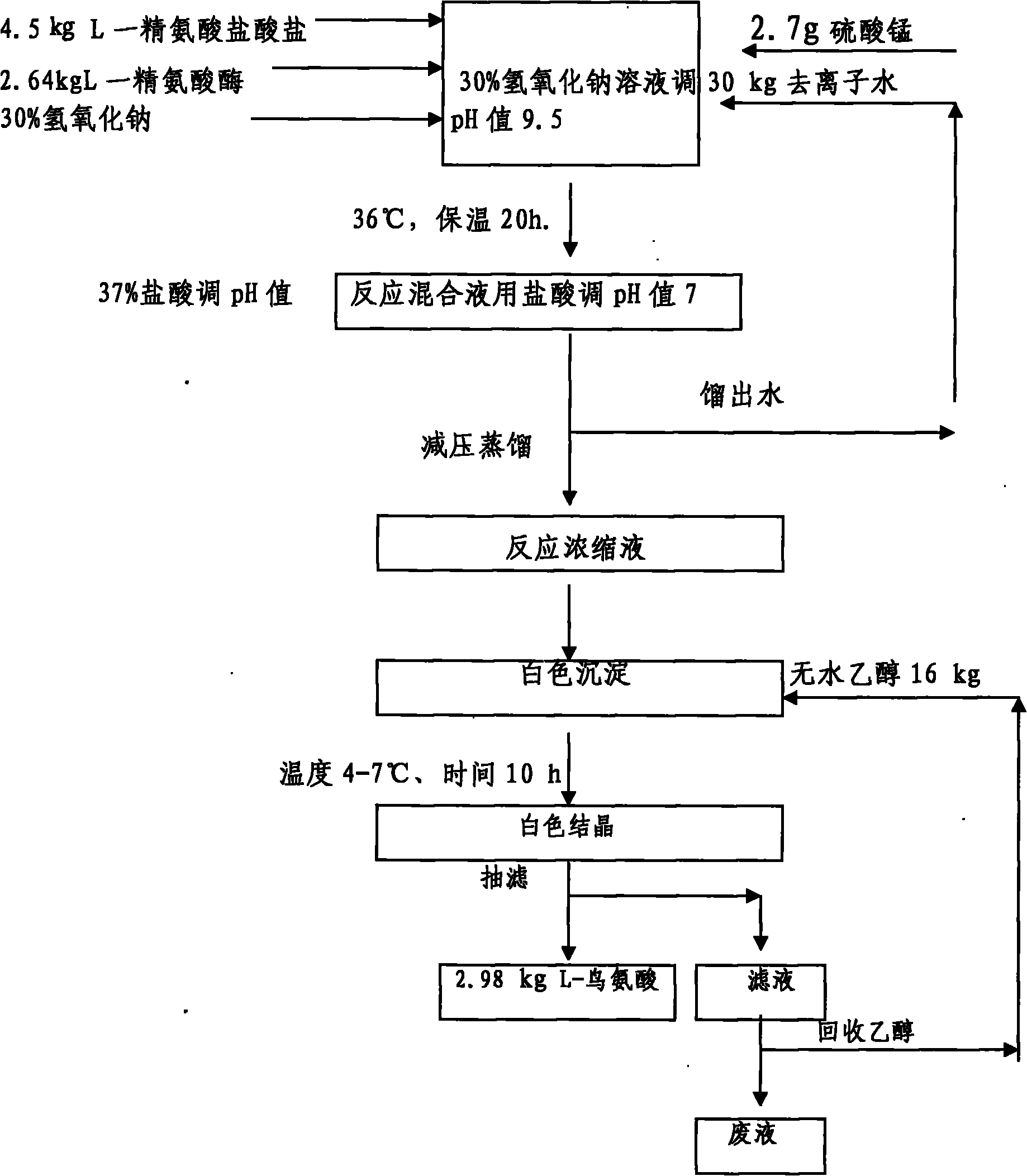

Image

Examples

Embodiment 1

[0019] Embodiment 1: A method for enzymatically preparing L-ornithine, mainly comprising the following steps:

[0020] ①. Feeding: Add 4.5kgL-arginine hydrochloride and 2.7kg manganese sulfate into a jacketed reactor with a capacity of 100L, then add 30kg of deionized water, and stir evenly, then measure the pH value 6, add 30% sodium hydroxide solution to adjust the pH value of the solution in the reactor to 9.5, then add 2.64 kg (5.8 million units) of L-arginase;

[0021] ②. Reaction: Control the steam and circulating water volume of the reactor to keep the temperature in the reactor at 36°C, keep the temperature for 20 hours, and obtain the reaction liquid after the reaction;

[0022] ③. pH adjustment: adjust the pH of the reaction solution to 7 with 37% hydrochloric acid to obtain a neutral solution;

[0023] 4. Concentration: Carry out vacuum distillation to described neutral liquid, distill off about 22kg of water, obtain concentrated liquid;

[0024] ⑤. Precipitation:...

Embodiment 2

[0030] Embodiment 2: present embodiment is the trial production that certain factory does according to the present invention, and concrete method is with embodiment 1, and concrete data sees table 1 below:

[0031] Table 1

[0032]

[0033] The solvent prepared by the enzymatic method of the present invention is deionized water, and the reaction materials include L-arginine hydrochloride, L-arginase, manganese sulfate and concentrated hydrochloric acid, and the raw materials used for extracting L-arginase include bovine liver , Tris-HCl buffer and a small amount of manganese chloride are non-polluting raw materials. The deionized water used in the reaction process and the anhydrous ethanol used in the post-treatment process can be recycled and recycled, which can greatly save costs. The final reaction The waste liquid contains enzymes, which can be removed by heating to make it solid. A small amount of manganese sulfate solution and urea are free of pollutants and can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com