Solar cell and manufacturing method thereof

A technology for solar cells and manufacturing methods, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

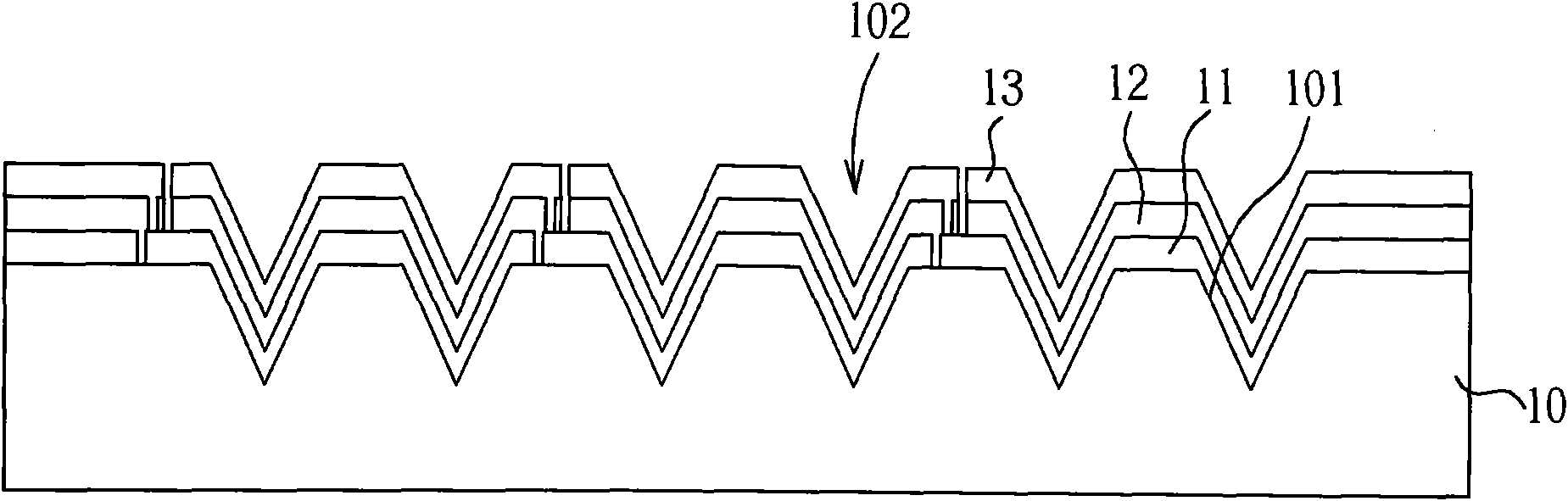

[0027] The structure of the solar cell designed in the present invention includes a substrate 10, a conductive layer 11, a copper indium gallium selenide (CIGS) layer 12, and a transparent conductive layer 13, wherein:

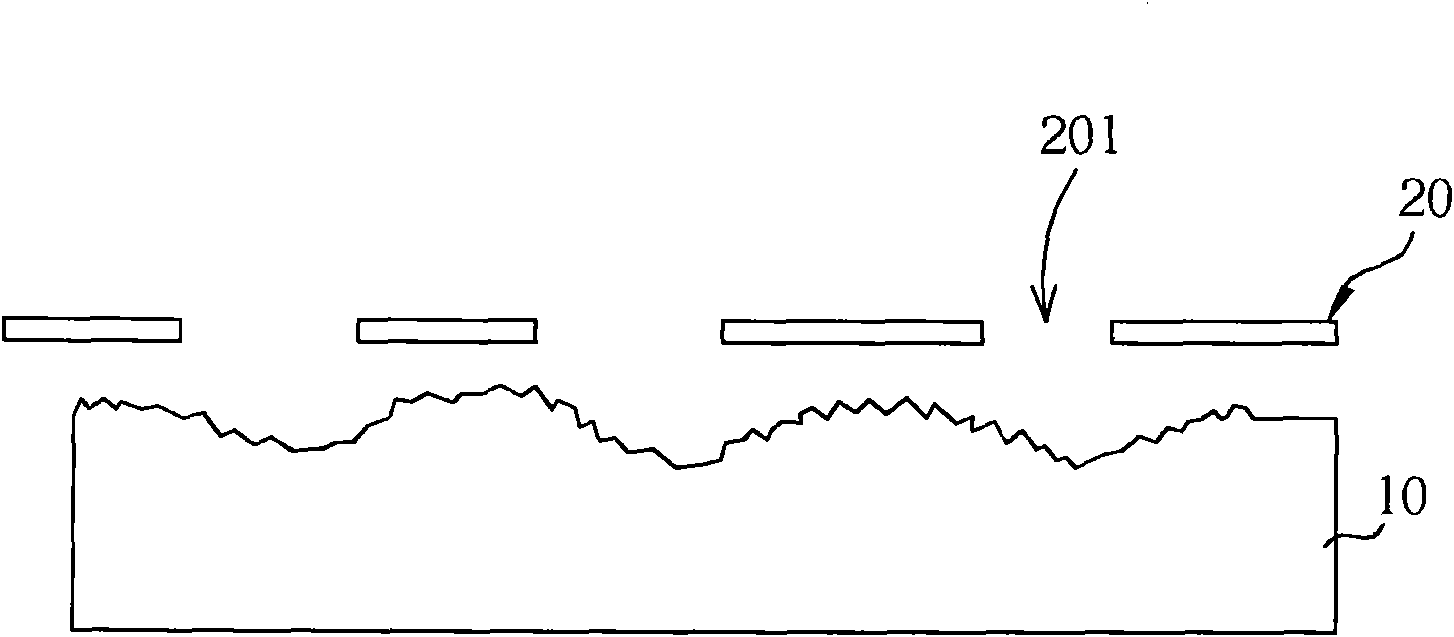

[0028] The substrate 10 can be made of glass or plastic, and its upper surface forms a non-flat active surface 101 with continuous peaks and valleys. In this specific embodiment, a plurality of concave holes 102 are formed on the upper surface of the substrate 10. To form the non-flat active surface 101 , the cavity 102 can be a cavity in the shape of a V-shaped groove, an inverted cone, an inverted pyramid, or the like.

[0029] The conductive layer 11 can be metal molybdenum (Mo) and is formed on the uneven active surface 101 of the substrate 10 with a plurality of cavities to form a film with continuous peaks and valleys.

[0030] The copper indium gallium selenide (CIGS) layer 12 is copper indium gallium diselenide (CuIn 1-x Ga x Se 2 ) compound is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com