Method for controlling quality of cooling liquid

A quality control method and cooling fluid technology, applied in the direction of measuring devices, weighing by removing certain components, instruments, etc., can solve the problem of fouling on the surface of equipment or the growth of corrosion microorganisms, damage to the process performance of circulating cooling equipment, and sediment adhesion and other problems, to achieve the effect of inhibiting scaling tendency and corrosion tendency, ensuring quality and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As can be seen from the background technology, the inventors of the present invention have found that in the existing cooling technology, during the continuous circulation of the cooling liquid, due to the combined effect of various factors, serious deposits will be attached, fouling or corrosion on the surface of the equipment and A large number of microorganisms will destroy the circulation cooling equipment and its process performance.

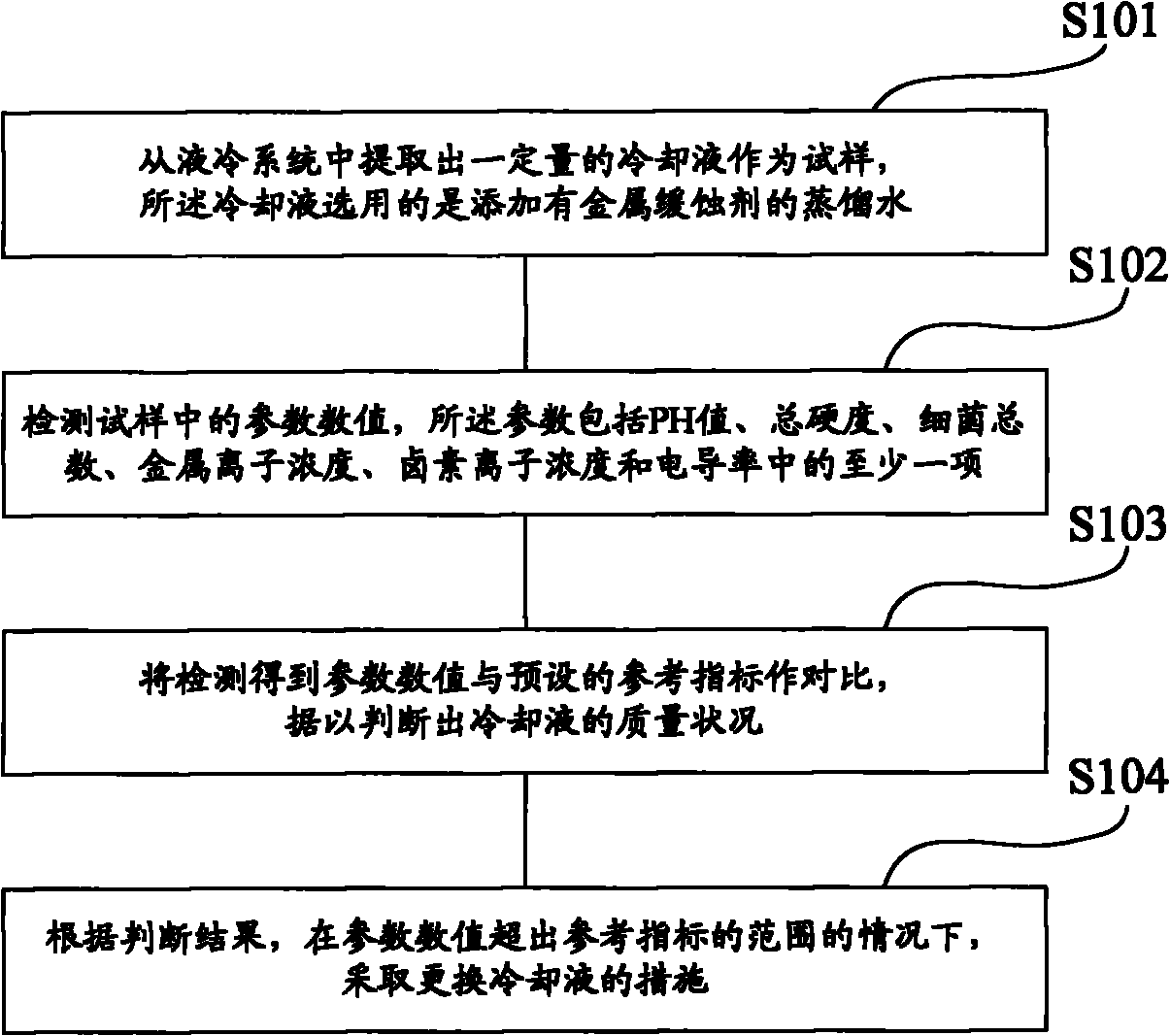

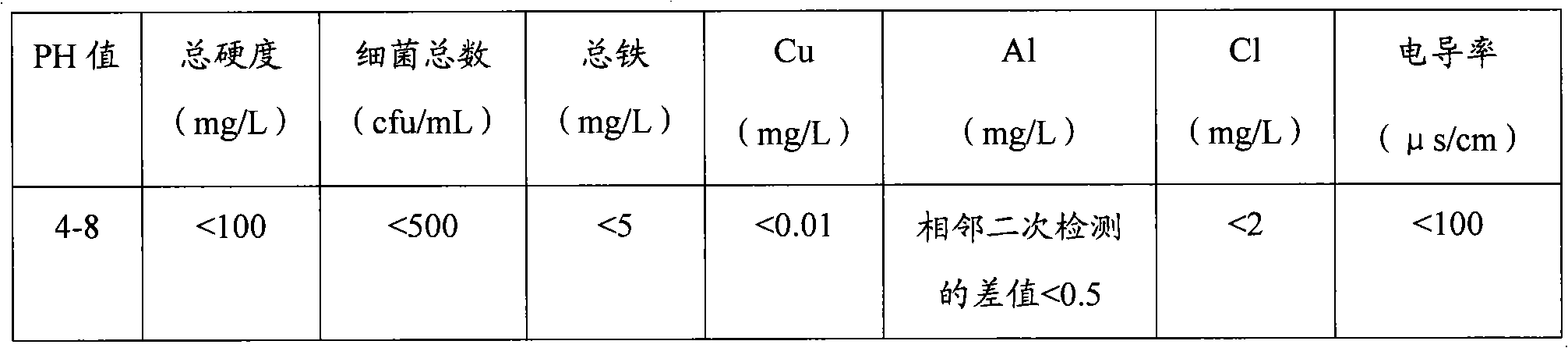

[0026] The inventors of the present invention creatively found that a metal corrosion inhibitor with anti-corrosion effect was added to the cooling liquid, and by monitoring the cooling liquid in real time, it was detected that the parameter values in the cooling liquid did not meet the preset reference Under the situation of index, take the measure of replacing new coolant, solve the problem that occurs in the prior art.

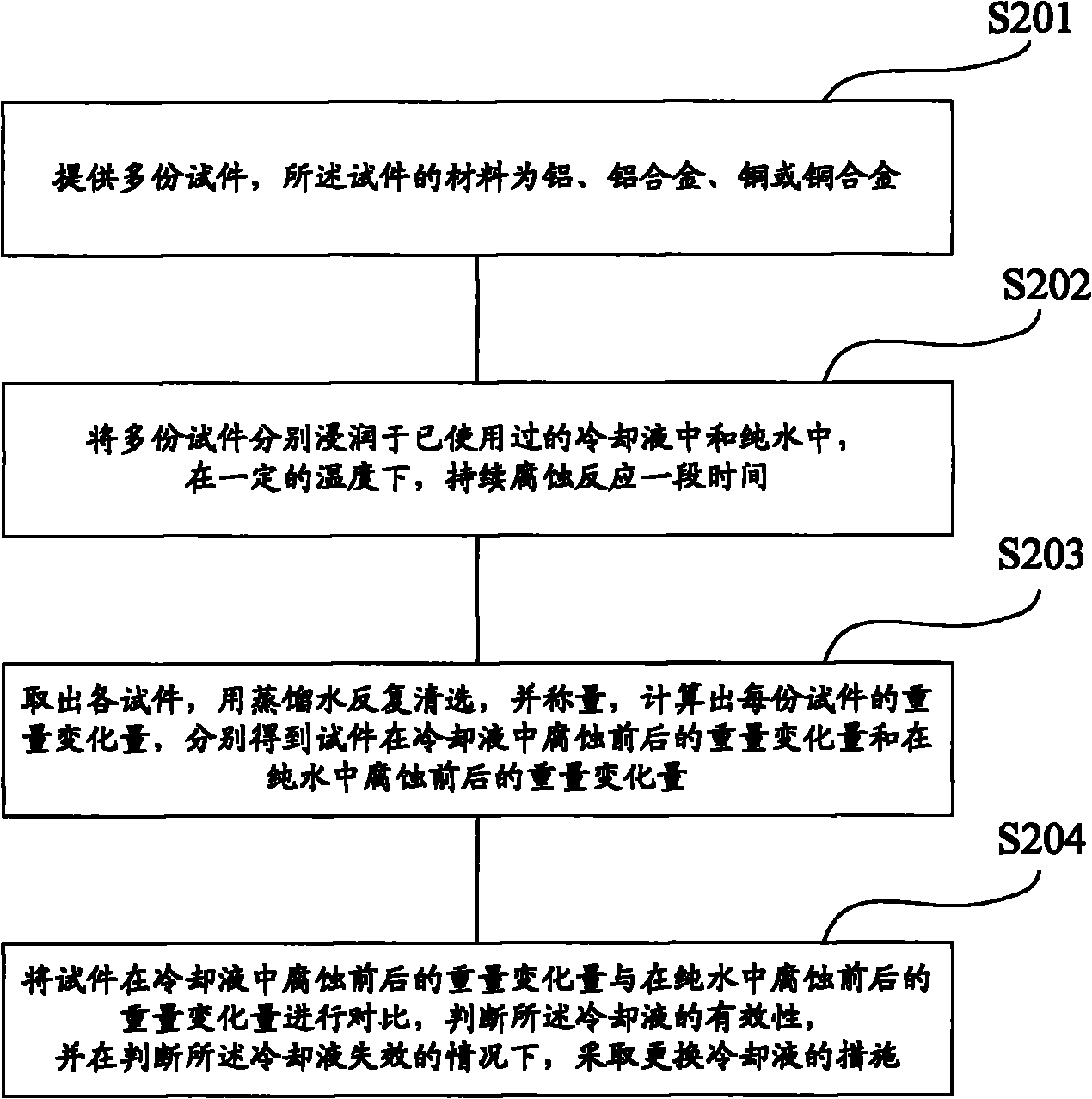

[0027] The content of the present invention will be described in detail below in conjunction with the accompa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power consumption | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com