Method for preparing pine-like cadmium sulfide from ethylenediamine type ionic liquid

An ethylenediamine-type, ionic liquid technology, applied in the direction of cadmium sulfide, etc., can solve the problems of unfavorable industrialization of nanomaterials, complicated preparation procedures, and high cost, and achieve the effects of low cost, high purity, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 30ml of ethylenediamine-type ionic liquid and mix with 10ml of deionized water, add 0.3g of thiourea and 0.3g of cadmium chloride dihydrate and stir until a transparent solution is formed. Then it was transferred to a 50ml autoclave and heated at 180°C to 200°C for 12h. After the reaction, the product was isolated, washed to remove impurities, and dried at 80°C for 6h.

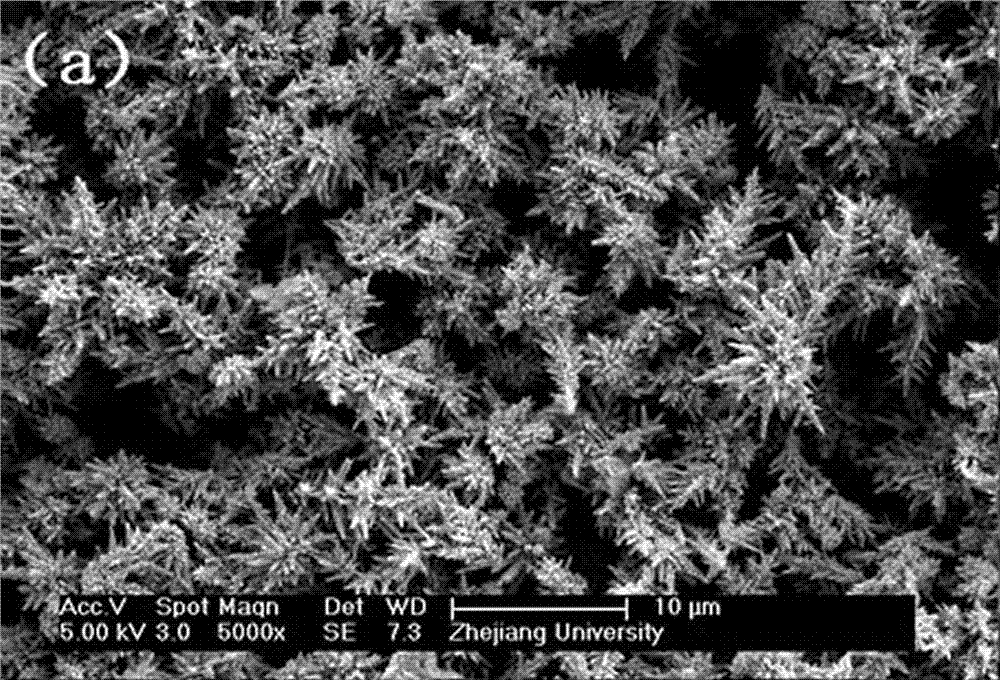

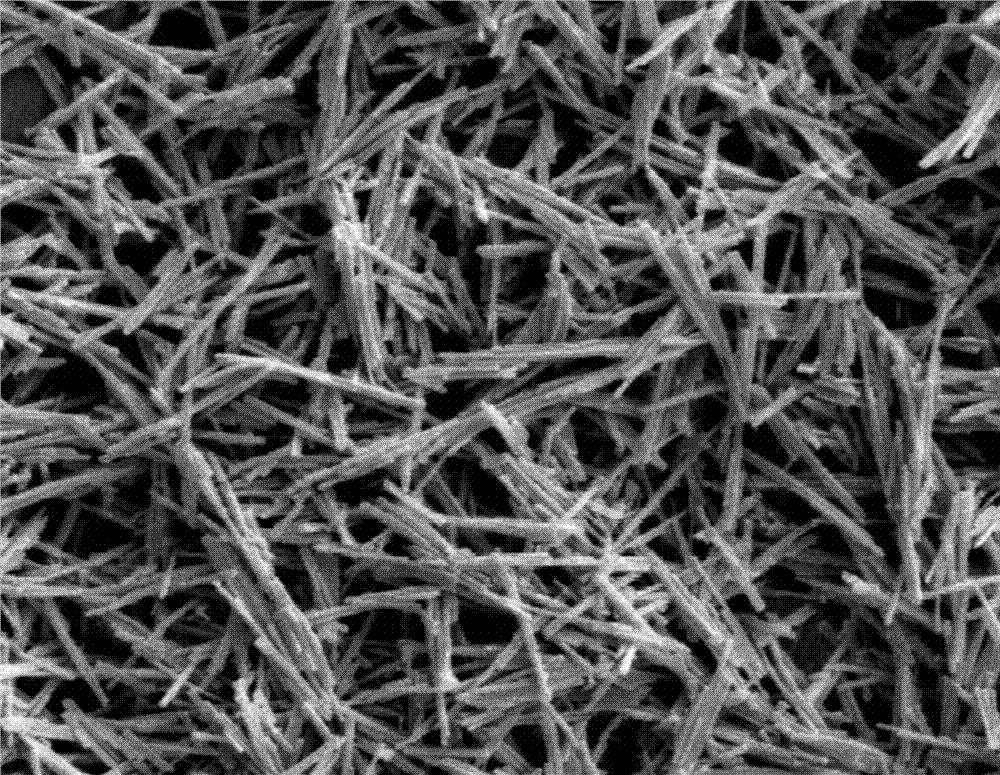

[0021] observed directly under a field emission scanning electron microscope. figure 1 , it can be seen from the figure that the overall shape of the product is pine-like, the purity is very high, and there is no other shape. Each branch is a rod-shaped structure, and the top of the rod is sharper, but the length and thickness of the rods are quite different.

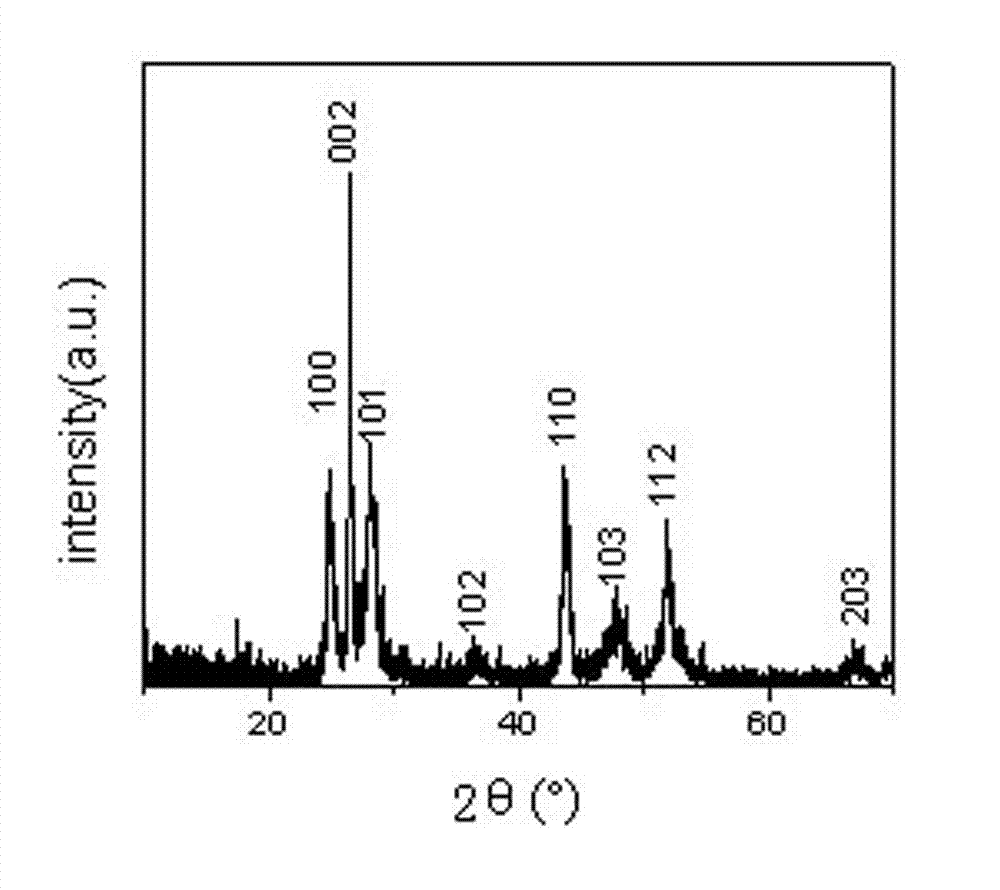

[0022] figure 2 is the XRD pattern of the sample. After calibration, all diffraction peaks are consistent with the standard spectrum (PDF.No 41-4019), and no other impurity peaks are found. After analysis, the obtained product belongs t...

Embodiment 2

[0024] Take 30ml of ethylenediamine-type ionic liquid and mix with 10ml of deionized water, add 0.3g of thiourea and 0.3g of cadmium chloride dihydrate and stir until a transparent solution is formed. Then transfer to a 50ml autoclave and heat at 180°C to 200°C for 14h. After the reaction, the product is isolated, washed to remove impurities, and dried at 80°C for 6h.

[0025] The morphology and figure 1 basically the same.

Embodiment 3

[0027] Take 30ml of ethylenediamine-type ionic liquid and mix with 10ml of deionized water, add 0.3g of thiourea and 0.3g of cadmium chloride dihydrate and stir until a transparent solution is formed. Then transfer to a 50ml autoclave and heat at 180°C to 200°C for 16h. After the reaction, the product is isolated, washed to remove impurities, and dried at 80°C for 6h.

[0028] The morphology and figure 1 basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com