Vibration suppression device

A vibration suppression and chattering technology, applied in the direction of manufacturing tools, maintenance and safety accessories, measuring/indicating equipment, etc., can solve the problems of poor time efficiency and achieve the effect of preventing damage and suppressing chattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

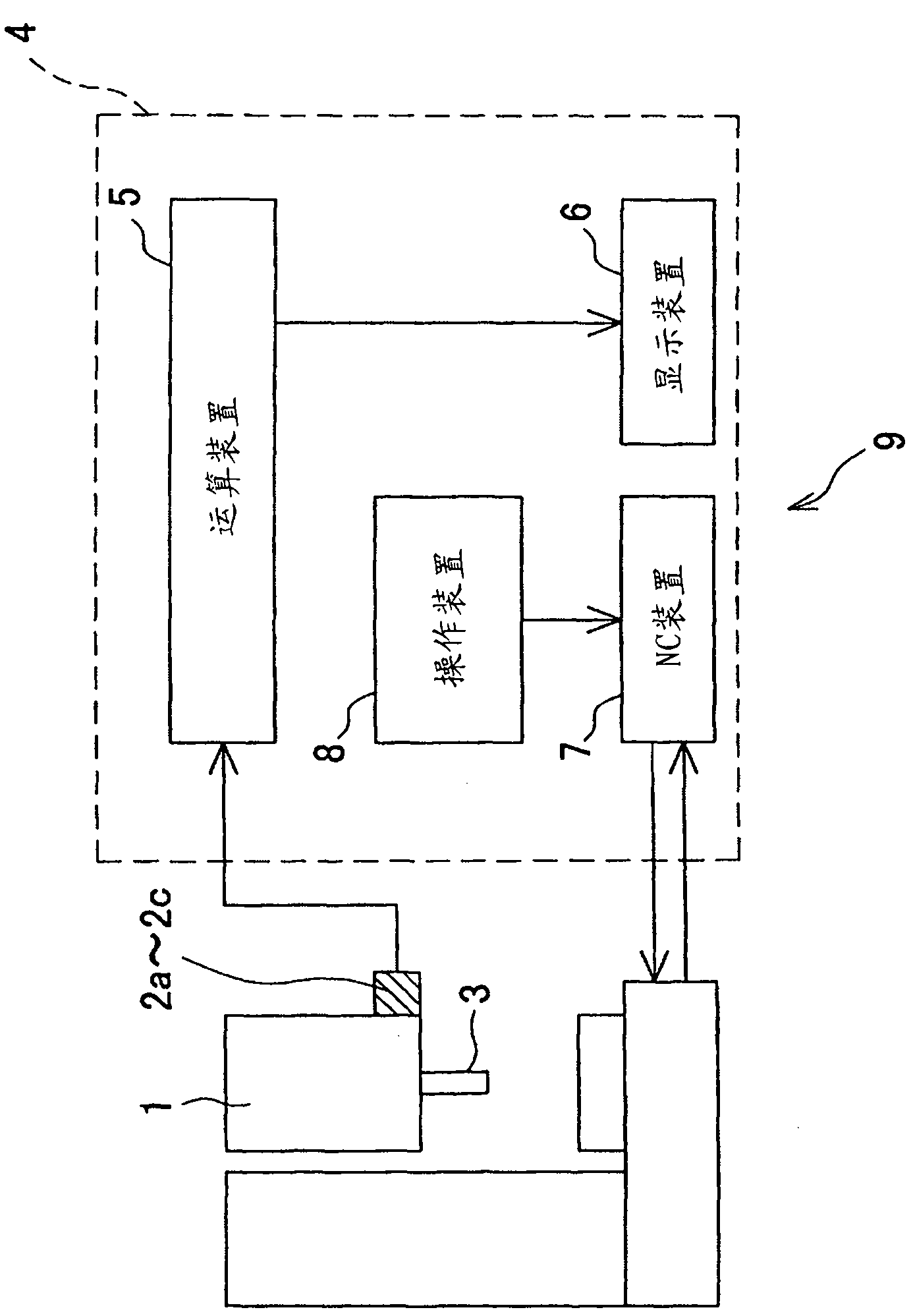

[0037] Hereinafter, a vibration suppressing device as an embodiment of the present invention will be described in detail with reference to the drawings.

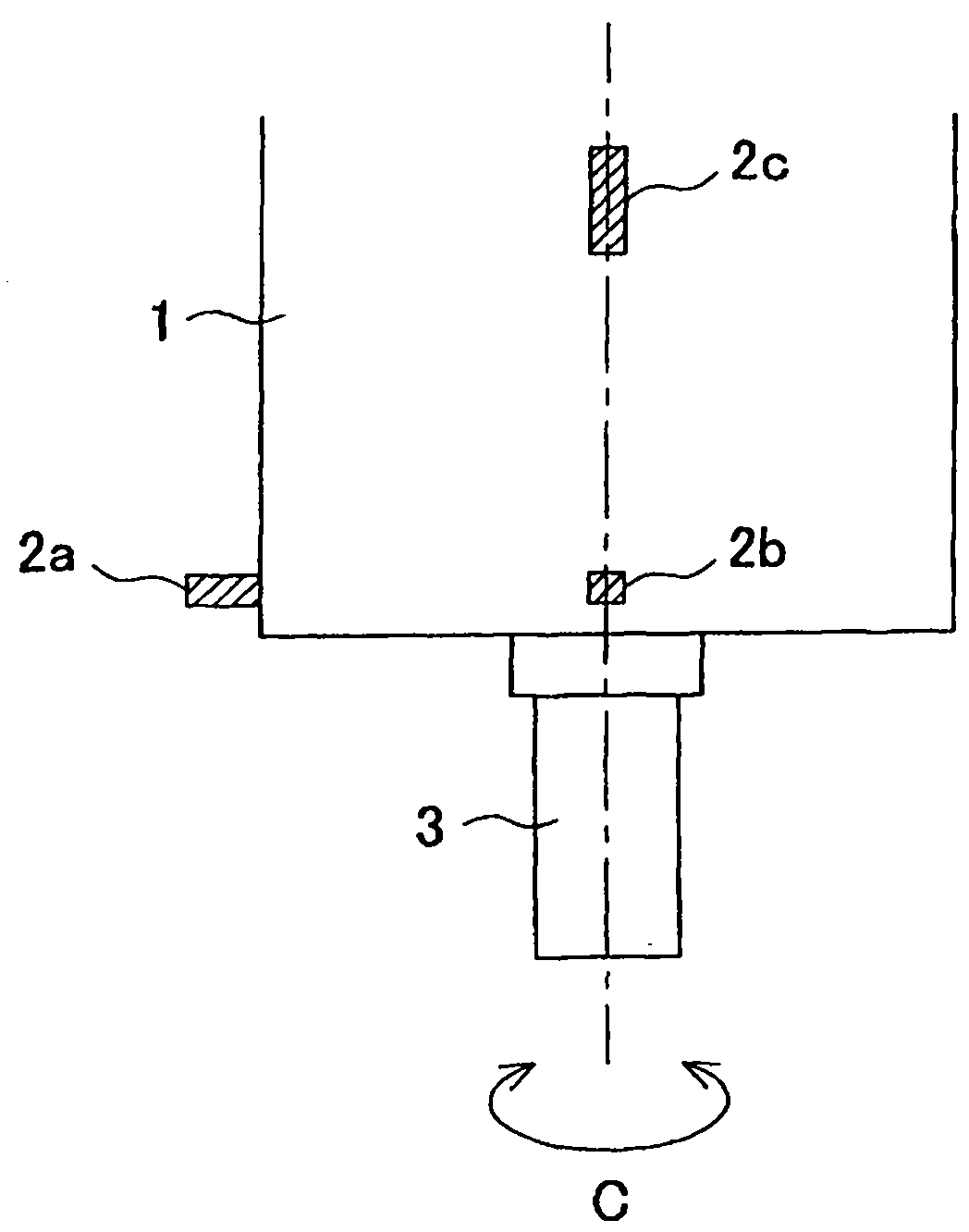

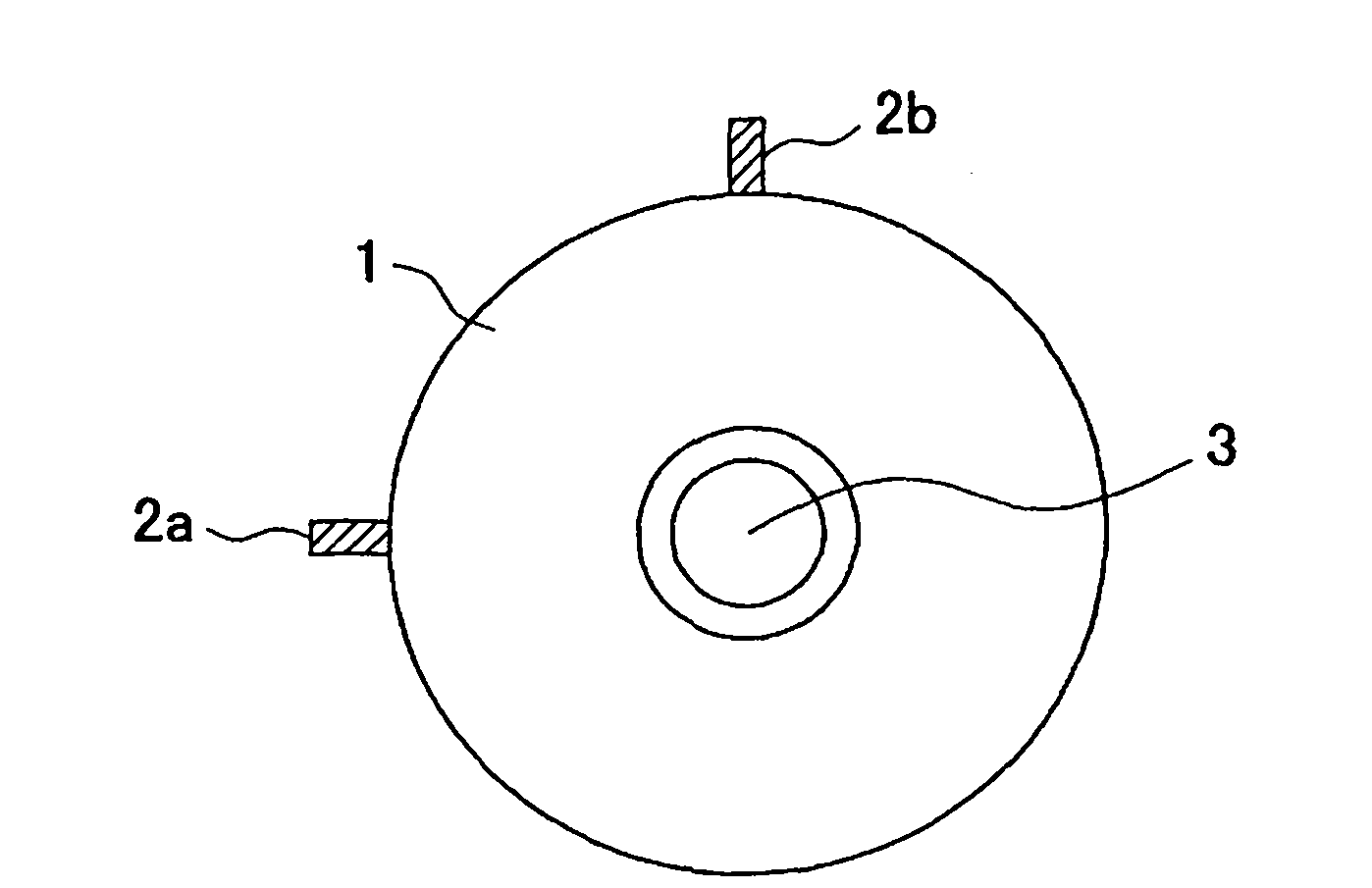

[0038] The vibration suppressing device 9 is a device for suppressing "chatter" generated on the rotating shaft 3, which is provided in the rotating shaft housing 1 in a manner to be rotatable around the C axis, and is used for detecting Vibration sensors 2a to 2c for vibration acceleration generated by the rotating shaft 3 and a control device 4 for controlling the rotational speed of the rotating shaft 3 based on detection values detected by the vibration sensors 2a to 2c are configured.

[0039] Such as figure 2 and image 3 As shown, the vibration sensors 2a to 2c are mounted on the rotating shaft housing 1, and one vibration sensor detects vibration acceleration in a direction perpendicular to the other two vibration sensors. Therefore, the vibration accelerations in the X-axis, Y-axis, and Z-axis directions orthog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com