Non-volatile memory device as well as non-volatile memory and manufacturing method thereof

A technology of non-volatile storage and manufacturing method, applied in the field of non-volatile storage devices, can solve the problems of difficulty in further shrinking, low manufacturability yield, etc. The effect of programming voltage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

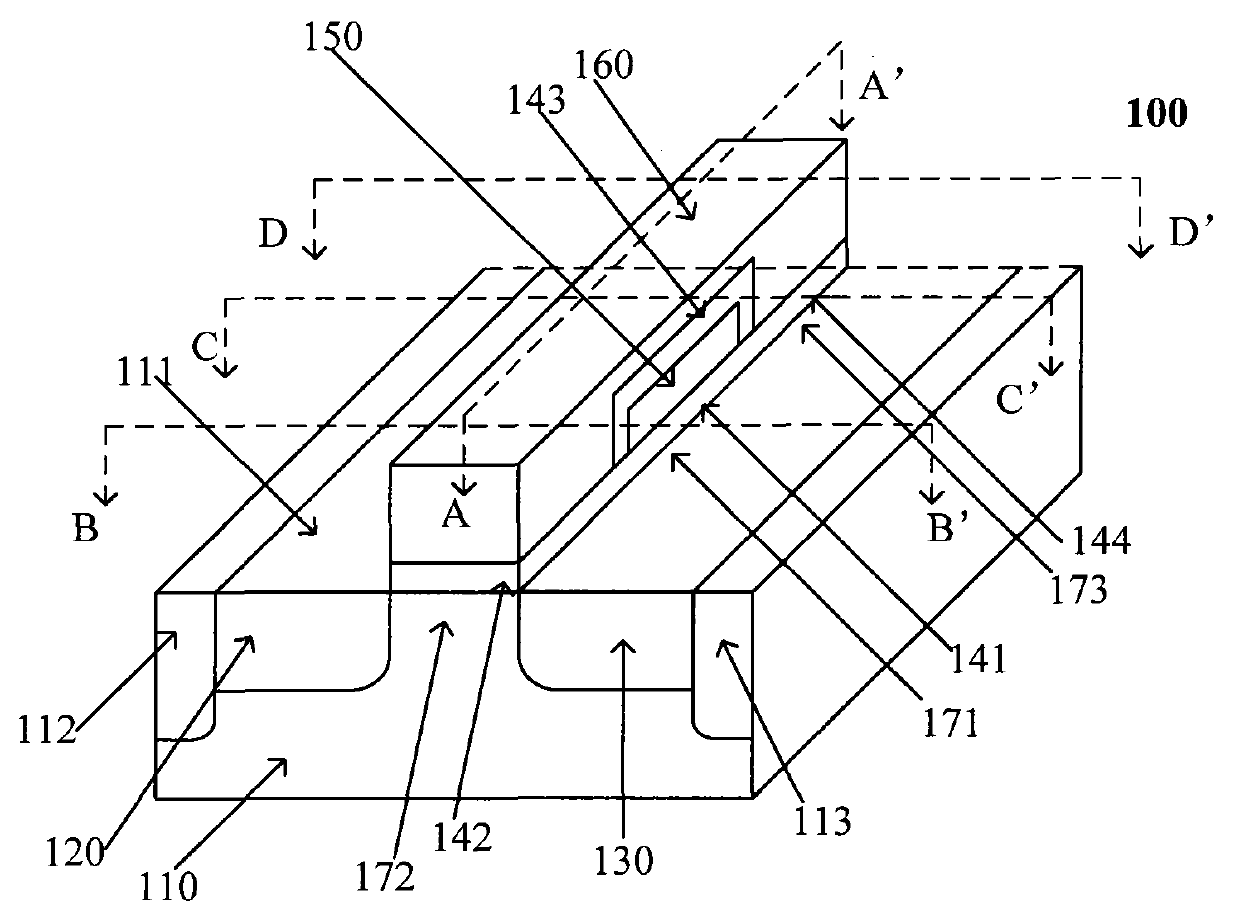

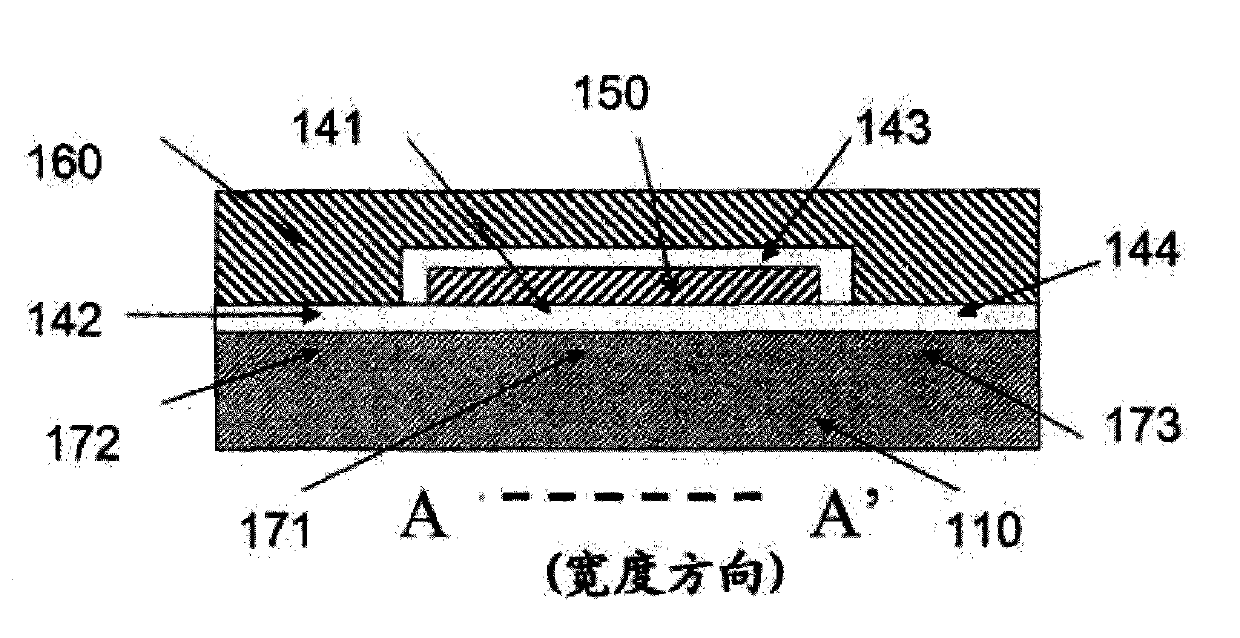

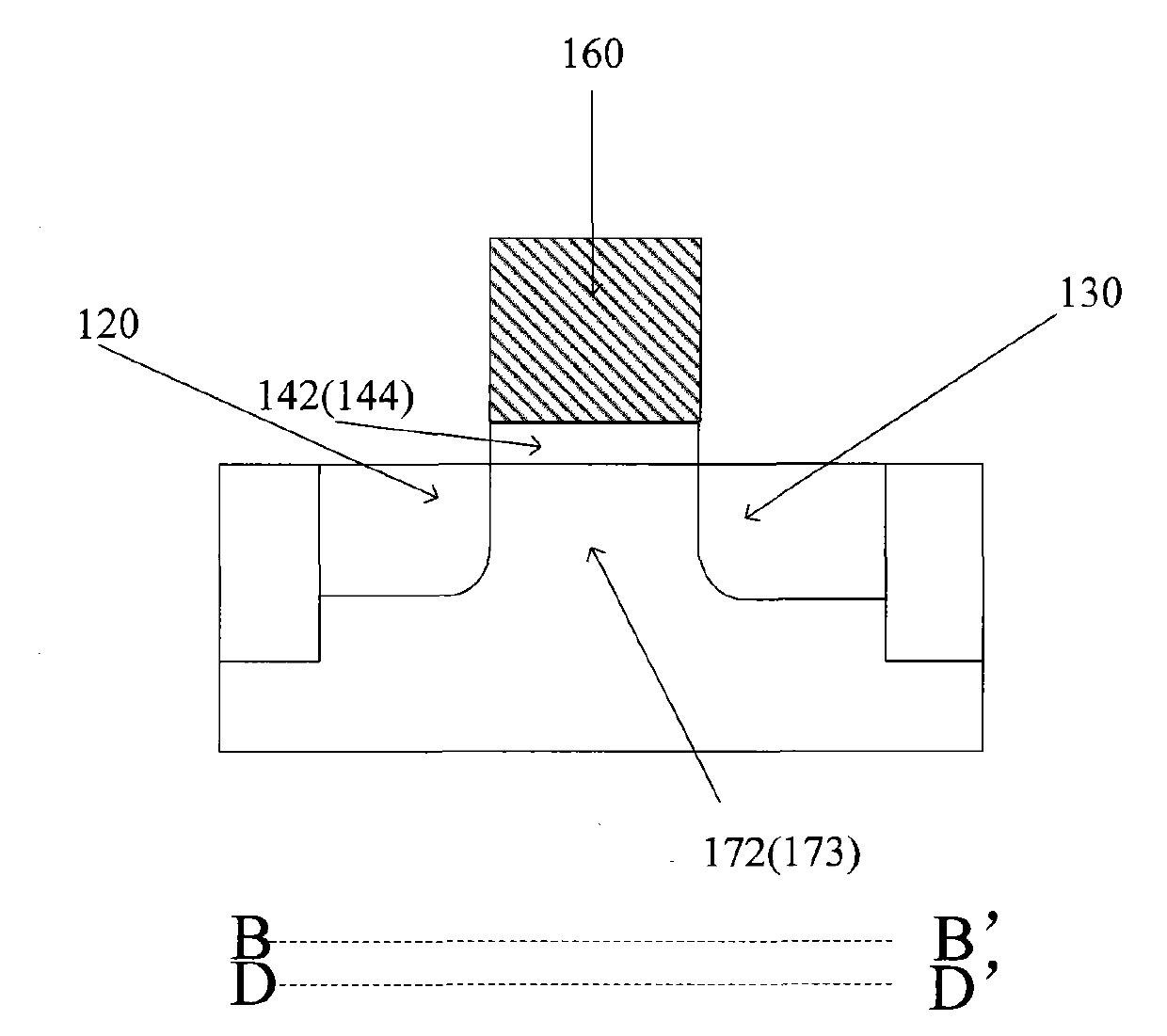

[0037] It can be seen from the background art that the existing non-volatile memory devices have many disadvantages, for example, when the logic devices are adjusted and designed to work at lower voltages, the non-volatile memory devices are difficult to scale down, and high voltage is still required. voltage to operate. For example, existing stacked nonvolatile memory devices require only a single transistor per cell, but require high programming currents, making it difficult to program and erase using on-chip high voltage generation. Existing split-gate nonvolatile memory devices are single-transistor electrically programmable and rewritable memory cells. Erasing of the cell is accomplished by the Fowler-Nordheim tunneling mechanism from the floating gate through the second insulating layer to the control gate. Electrons from the source migrate through the channel region below the control gate and are injected into the floating gate through the first insulating layer due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com