System and method for improving beam current intensity distribution after leading ion beam out

A technology of ion beam and beam current, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of unfavorable time efficiency, long time required, and reduction of beam current, so as to improve the distribution of beam current intensity and reduce beam current Effects of loss and beam enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] based on the following Figure 3 ~ Figure 8 , specify the preferred embodiment of the present invention:

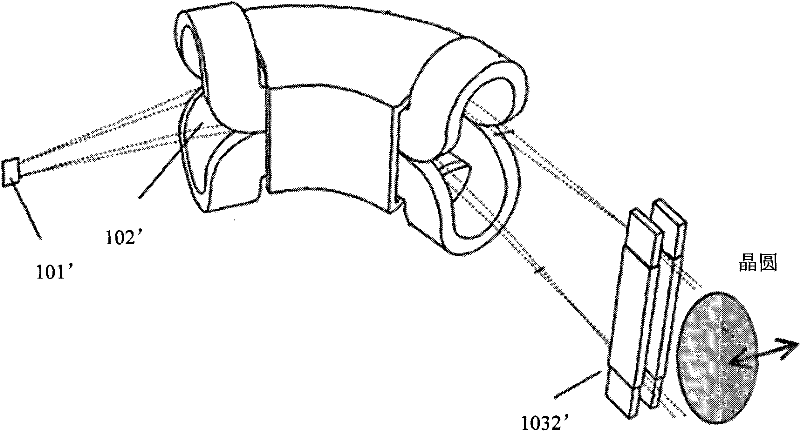

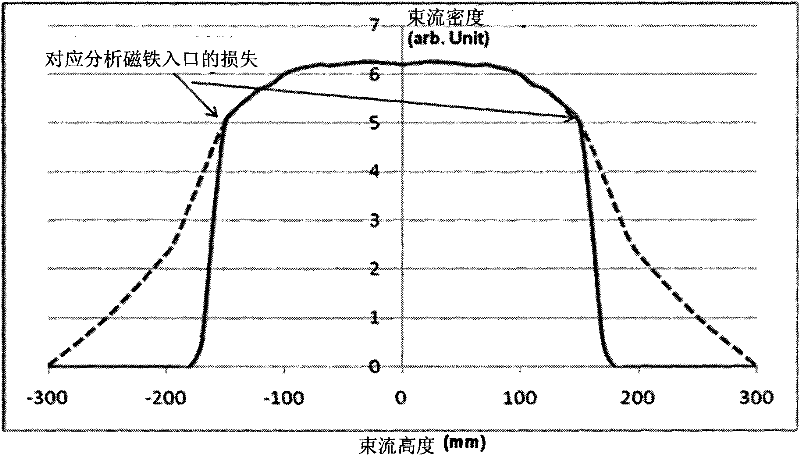

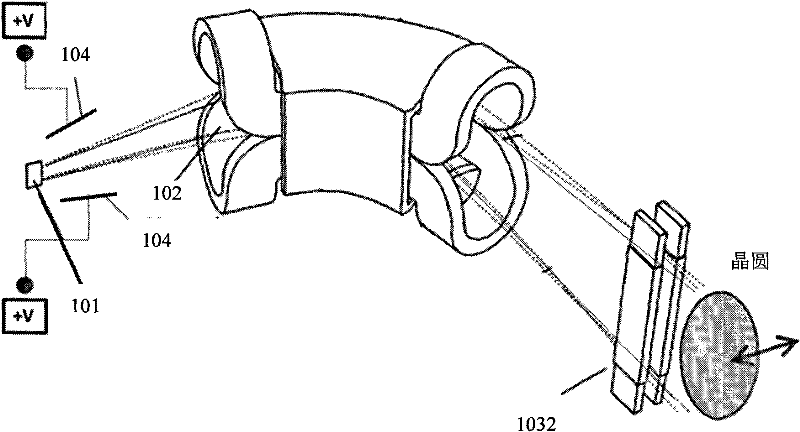

[0035] Such as image 3 As shown, it is a system to improve the beam intensity distribution after the ion beam is extracted, including:

[0036] The ion source generates an ion beam;

[0037] The beam extraction system 101 is used to obtain divergent ion beams through divergent extraction electrodes;

[0038] Mass analysis magnet 102 for selecting the ion beam of required energy;

[0039] The beam uniformity controller 1031 is used to adjust the density distribution of the beam in the longitudinal direction; in this embodiment, while adjusting the density distribution of the beam in the longitudinal direction, the beam uniformity controller 1031 can also realize the first The function of an angle controller;

[0040] The calibrator 1032 terminates the divergence tendency of the beam current, and makes the beam current propagate in parallel to control the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com