Corrugated elastic seal and rotary air pre-heater sealing device

An air preheater and elastic sealing technology, applied in engine sealing, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve problems such as unsatisfactory service life, difficulty in making bristles, and air leakage gaps, etc., and achieve simple structure , Long service life, reduce the effect of air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

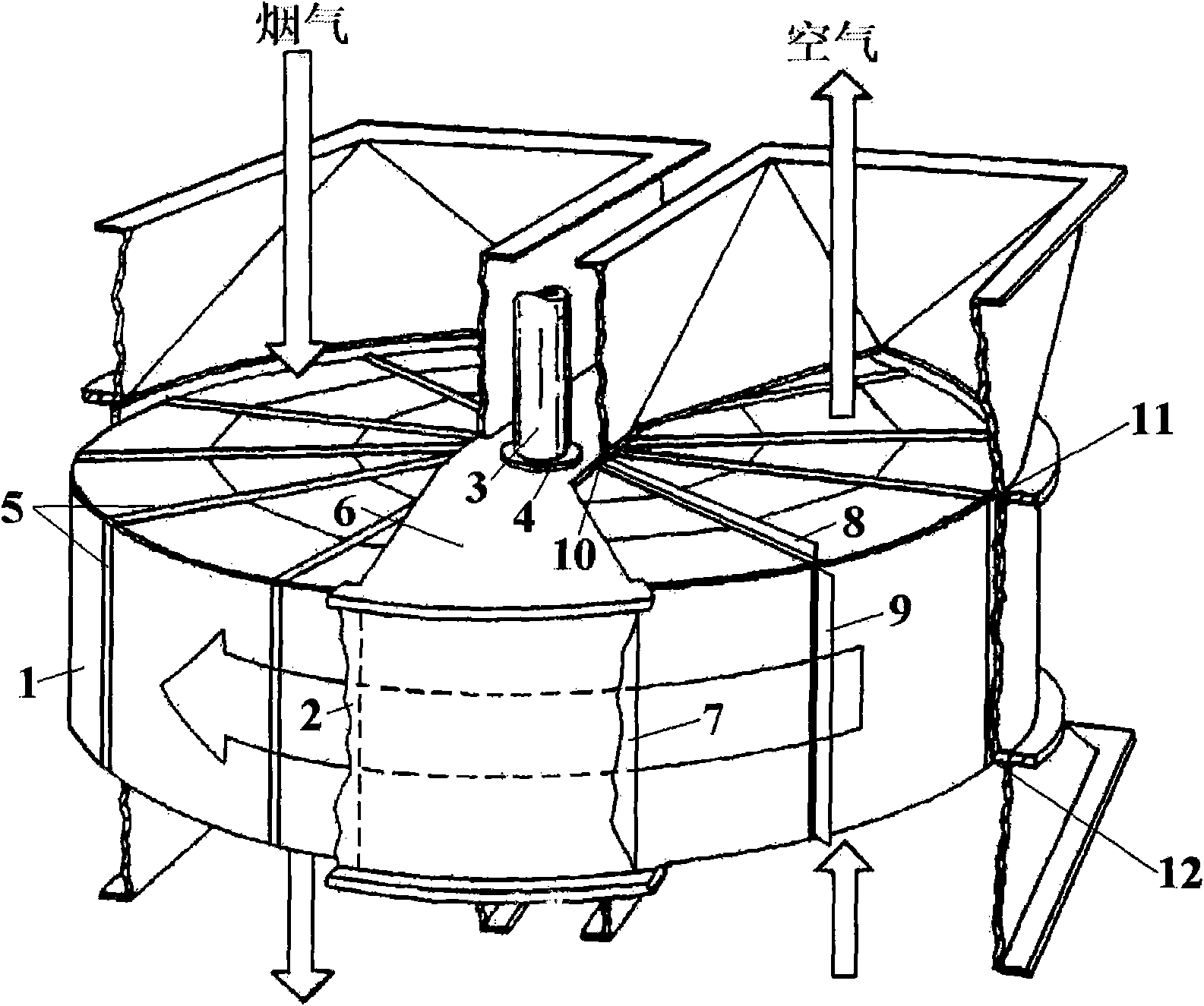

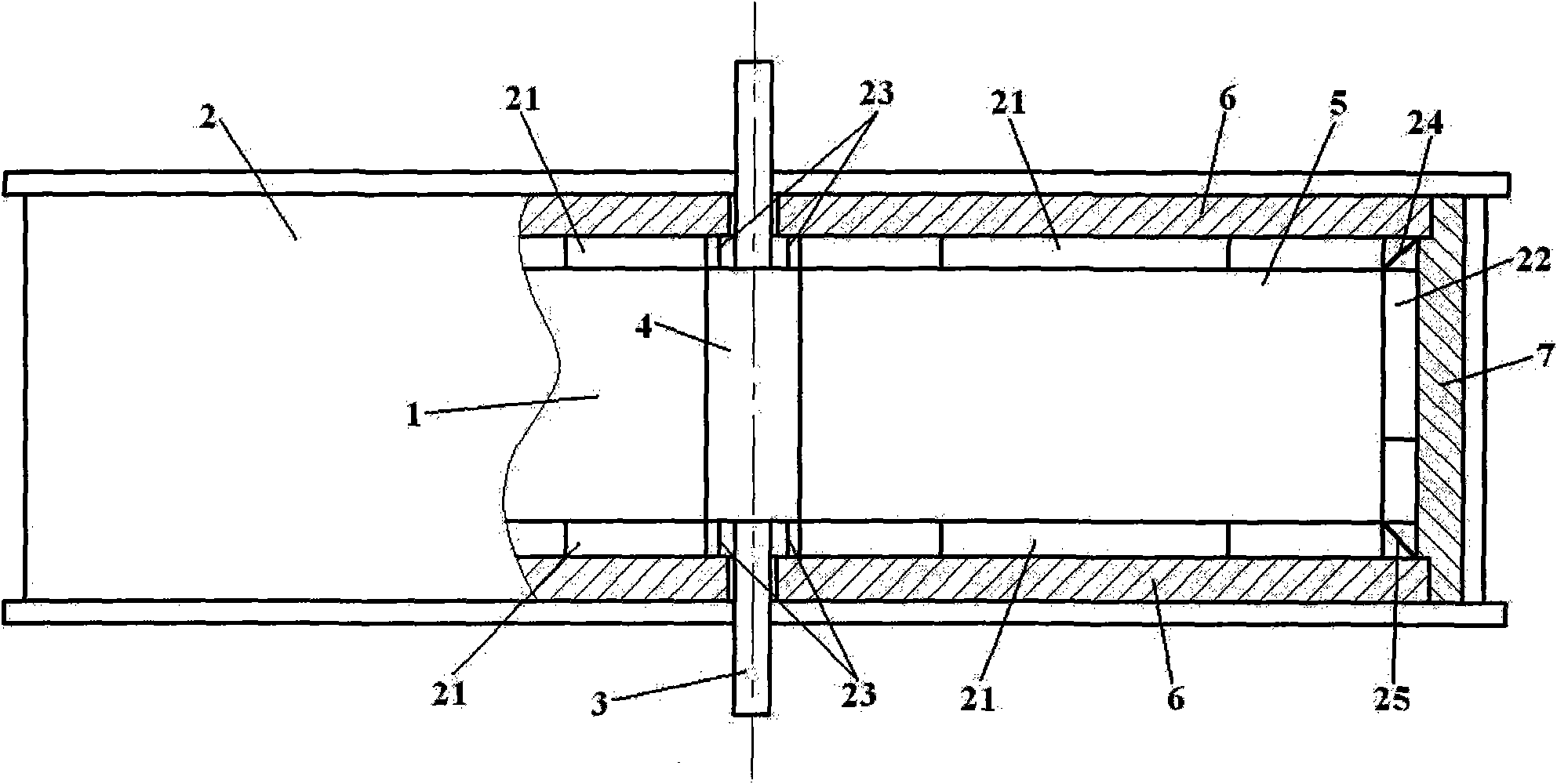

[0028] Taking the two-compartment rotary air preheater as an example, the main structure of the rotary air preheater of the present invention is as follows: figure 1shown. The rotor 1 installed in the shell 2 rotates slowly around the rotating shaft 3, and the rotor 1 is divided into several fan-shaped compartments by several compartment partitions 5 in the radial direction, generally 24 or 36 or 48 compartments, above and below the shell 2 There are two pairs of fan-shaped plates 6 (four in total) in the radial direction, two arc-shaped plates 7 in the axial direction of the casing 2, and radial seals 8 are installed radially at the hot and cold ends of each compartment partition plate 5 of the rotor 1 The radial corrugated elastic seal 21 is installed on the top, and the axial corrugated elastic seal 22 is installed on the position where the axial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrugation depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com