Component cooling water pump for nuclear power plant

A technology for cooling water pumps and nuclear power plants, which is applied to the components, mechanical equipment, pumps, etc. of the pumping device for elastic fluids, can solve the problems of large volume and poor shock resistance of cooling water pumps, and achieves improved shock resistance and improved operation stability. , the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

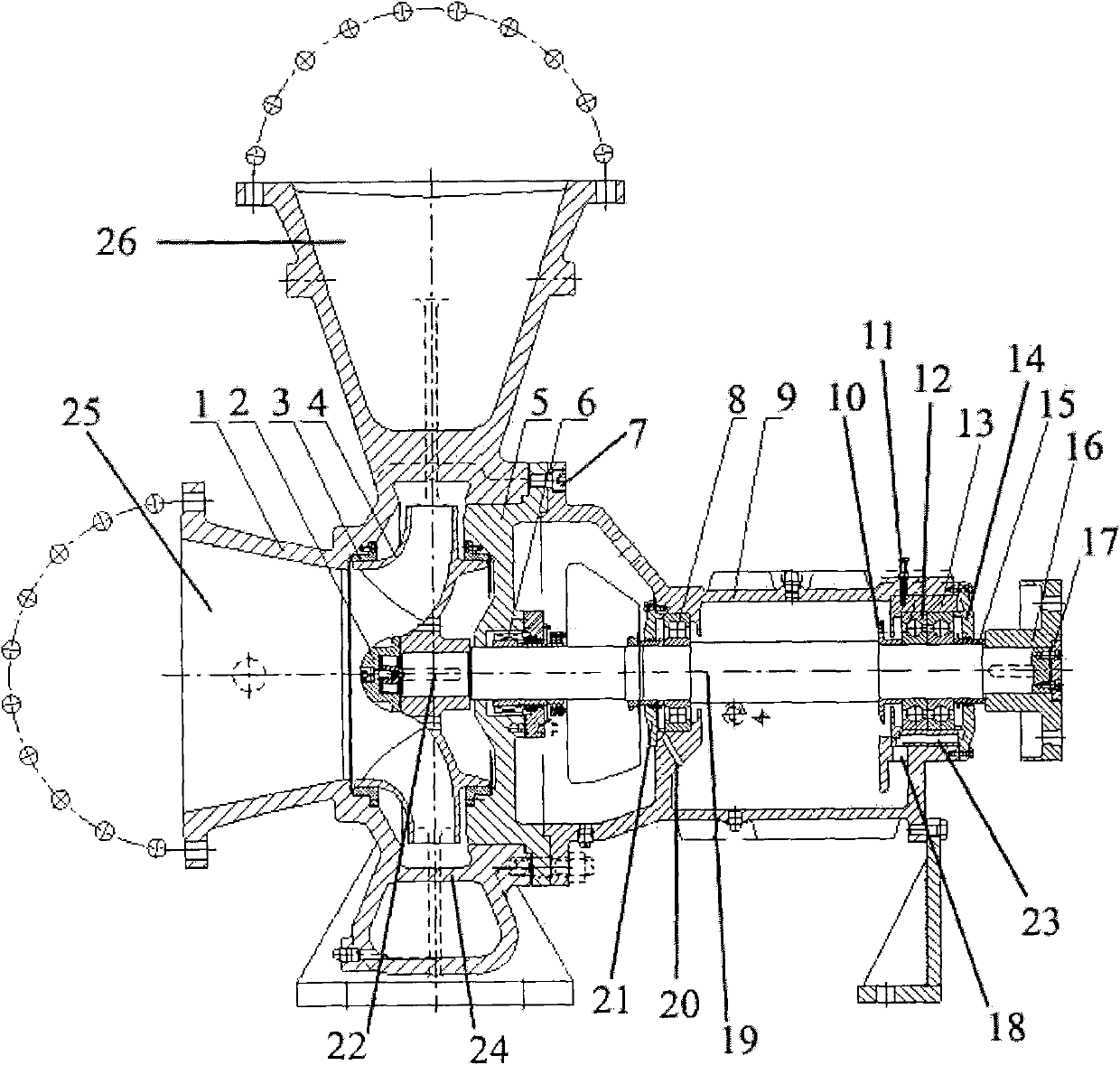

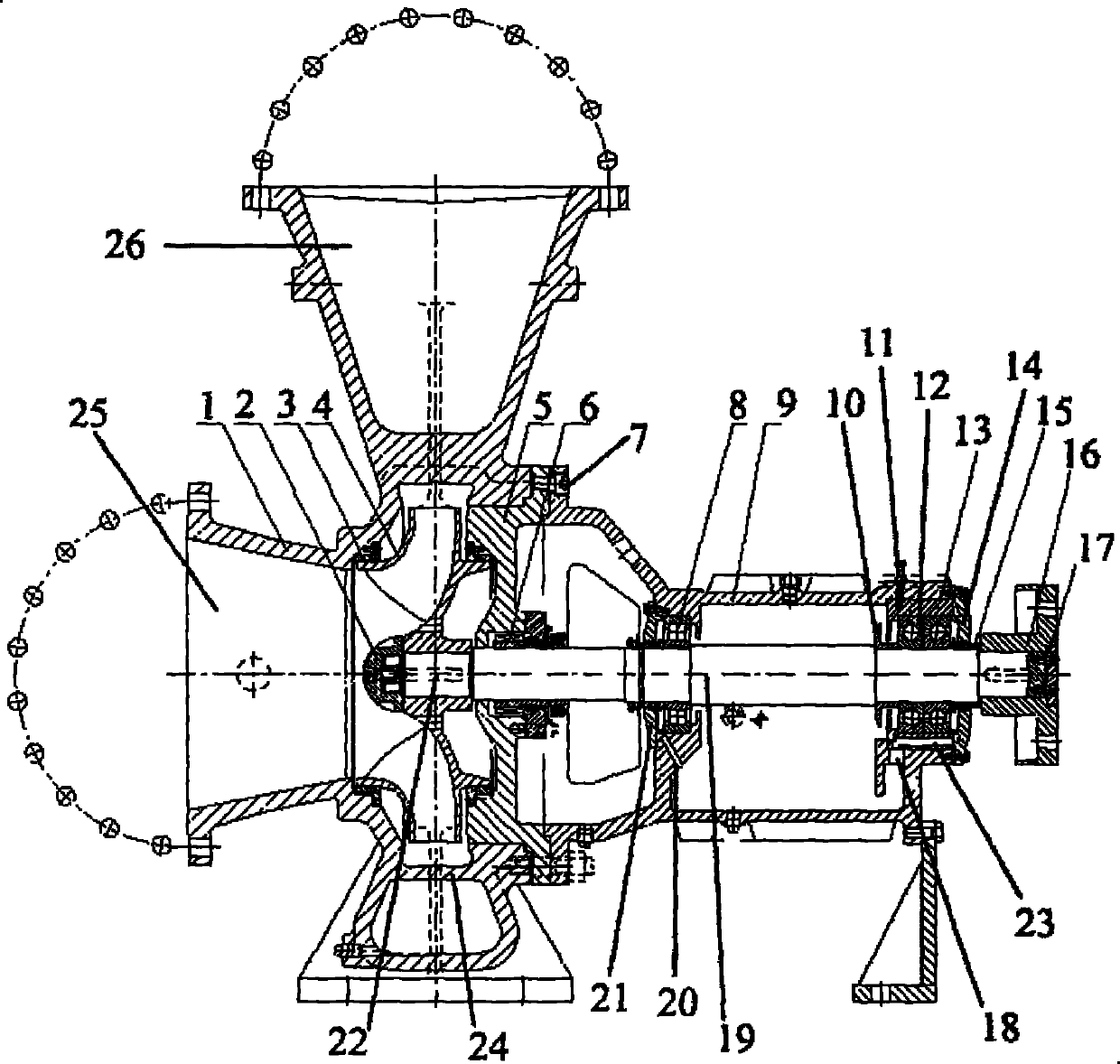

[0013] Such as figure 1 As shown, the equipment cooling water pump used in nuclear power plants in the present invention is composed of a stator assembly, a rotor assembly, a bearing assembly and a shaft seal assembly, wherein the stator assembly is composed of a pump body 1, a pump cover 5 and a bearing body 9, and the The rotor assembly described above is composed of pump shaft 19, impeller 4 and oil guide ring 10, the bearing assembly is composed of cylindrical roller bearing 8, angular contact ball bearing 12, front bearing cover 21 and rear bearing cover 14, and the described The pump body 1 is a radially split double volute structure, the pump body 1 is provided with an intermediate partition plate 24, the pump body 1 has a double volute structure, the suction port 25 is horizontally arranged at one end of the pump body 1, and the pump cover 5 is set At the other end of the pump body 1, the pump cover 5 is connected to the bearing body 9, the discharge port 26 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com