Method and device for plating cladding magnetic material on microorganism surface

A technology of microbial activity and microorganisms, applied in the field of preparing electromagnetic wave absorbing particles, can solve problems such as unsolved coating, and achieve the effects of reducing processing procedures, controllable electromagnetic properties, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

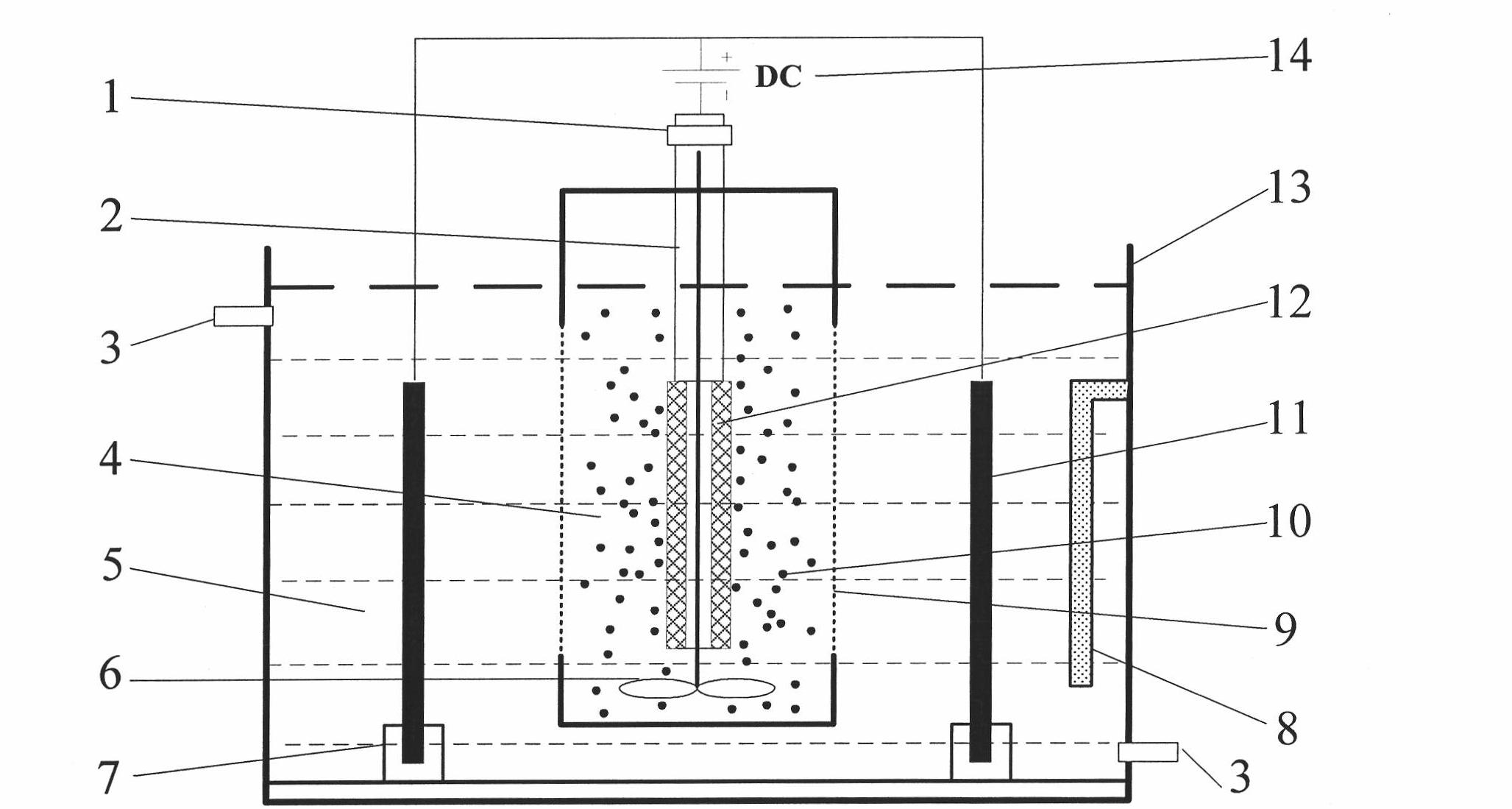

Method used

Image

Examples

Embodiment 1

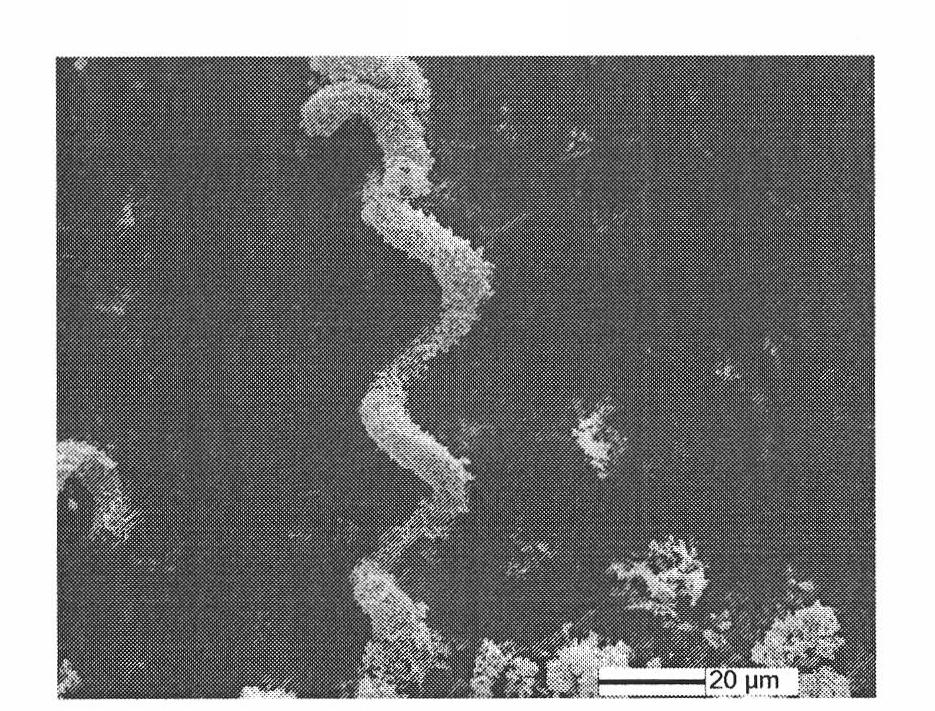

[0093] Example 1 : Electroplating-coated pure Ni bioparticles using spirulina as a template

[0094] This example adopts spirulina as the forming template. The microorganism is blue-green in color and has a regular helical structure. Generally, the helix width is 26 μm to 36 μm, the pitch is 43 μm to 57 μm, and the number of helices is 4 to 7, up to about 20.

[0095] Step 1: Template preprocessing

[0096] The spirulina was fully washed with phosphate buffer solution, and then fixed in a glutaraldehyde solution with a temperature of 4°C and a concentration of 2.5wt% for 4 hours to enhance its mechanical strength. After that, it was repeatedly washed and filtered with deionized water for 3 times, and then used for later use.

[0097] The dosage of spirulina and glutaraldehyde solution is: 1g spirulina needs 20mL glutaraldehyde solution.

[0098] Step 2: template conductive treatment

[0099] (A) Put the spirulina obtained in step 1 into the colloidal palladium activation ...

Embodiment 2

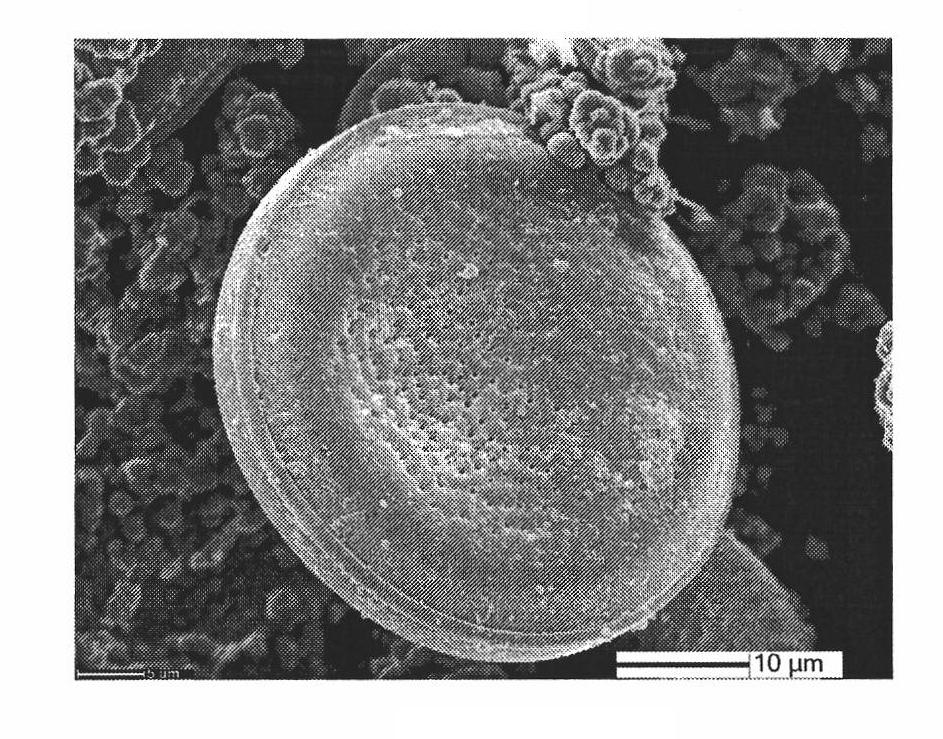

[0122] Example 2 : Electroplating-coated Ni-Fe bioparticles using diatomaceous earth as a template

[0123] In this example, diatomaceous earth is used as a forming template. The diatomite is off-white flaky powder with a particle diameter of 30-50 μm, a thickness of 2-5 μm and pores of 50-200 nm.

[0124] Step 1: Template preprocessing

[0125] The diatomite was coupled at a temperature of 30°C and a stirring speed of 220r / min for 4h, and then dried at a vacuum of -0.1MPa and a temperature of 120°C for 4h. The coupling solution used is 1.5 wt% APTES (γ-aminopropyltriethoxysilane) absolute ethanol solution.

[0126] The dosage of diatomite and coupling solution is: 1g diatomite needs 25mL coupling solution.

[0127] Step 2: template conductive treatment

[0128] (A) Put the diatomite obtained in step 1 into the colloidal palladium activation solution, activate it for 10 minutes at a temperature of 30°C and a stirring speed of 220r / min, then filter it with a 400-mesh silk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com