Cold-rolled galvanized duplex steel and manufacturing method thereof

A manufacturing method, hot-dip galvanizing technology, applied in the manufacture of converters, hot-dip galvanizing process, coating, etc., can solve problems such as the difficulty of dual-phase steel structure

Active Publication Date: 2013-06-19

BAOSHAN IRON & STEEL CO LTD

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, the maximum strength of hot-rolled dual-phase steel can reach 980MPa, and the maximum strength of cold-rolled dual-phase steel can reach 1200MPa, while the current maximum strength of hot-dip galvanized dual-phase steel can reach 980MPa. Because the hot-dip galvanizing annealing process must pass through 460 ℃ zinc liquid Temperature, at this temperature, bainite transformation is easy to occur, and it becomes difficult to obtain a dual-phase steel structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0032] The present invention is described in more detail by specific examples below.

[0033] The composition of embodiment is shown in table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

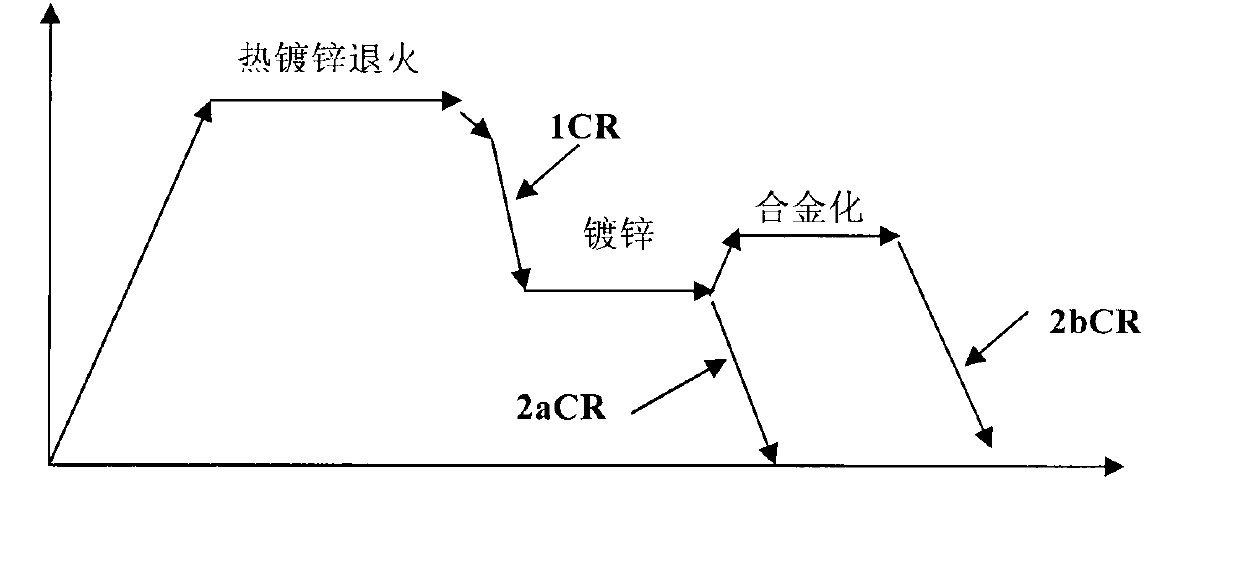

The invention relates to a cold-rolled galvanized duplex steel, wherein the substrate thereof comprises the following components by weight percentage: 0.08 to 0.18 wt.% of C, 0.50 to 1.50 wt.% of Si, 1.50 to 2.5 wt.% of Mn, 0.10 to 1.0 wt.% of Cr, 0.02 to 0.5 wt.% of Mo, 0.005 to 0.05 wt.% of Nb, 0.005 to 0.05 wt.% of Ti, 0.002 to 0.05 wt.% of T.Al, less than or equal to 0.02 wt.% of P, less thanor equal to 0.01 wt.% of S and less than or equal to 0.006 wt.% of N, and the balance of Fe. The manufacturing method thereof comprises the steps of: smelting in an oxygen top-blown convertor, refining in a heating steel ladle, continuously casting into a slab, and then conventionally hot rolling, pickling tandem rolling, galvanizing and annealing, wherein the critical annealing temperature is between 760 and 840 DEG C; the annealing is finished in the two-phase area of ferrite and austenite; 1CR section cooling has a cooling speed of 1 to 40 DEG C / S from the annealing temperature to the zincpool, putting the substrate into the zinc pool having a temperature of 450 to 465 DEG C so as to galvanize; and 2a CR section cooling has a cooling speed more than 3 DEG C / S. The steel of the invention has the advantages of high tensile strength, low yield ratio, capable of being press formed, excellent matching between strength and toughness, high rate of initially work-hardening and being free from yield extending.

Description

technical field [0001] The invention relates to low-alloy high-strength steel, especially 1180Mpa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof. Background technique [0002] Since the development of the automobile industry, energy saving and weight reduction, increased safety, and improved corrosion resistance of the car body have become the goals pursued by people. Therefore, the use of high-strength and galvanized steel sheets is an inevitable trend in the development of automotive steel. [0003] Dual-phase steel is currently the most widely used high-strength steel in the automotive industry. Dual-phase steel for automobiles can be divided into hot-rolled dual-phase steel, cold-rolled dual-phase steel and cold-rolled hot-dip galvanized dual-phase steel. Phase steel, cold-rolled hot-dip galvanized dual-phase steel has been commercialized, and the tensile strength levels mainly include 500MPa, 600MPa, and 800MPa, while 980MPa cold-roll...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/38C22C38/28C21C5/32C21C7/00B22D11/00C21D1/26C21D8/02C23C2/06C23C2/40C23F17/00

Inventor 张红

Owner BAOSHAN IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com