Process for preparing L-arginine-alpha-ketoglutarate (AAKG) from fermentation liquor through direct crystallization

A technology of ketoglutarate and ketoglutaric acid, which is applied in the preparation of carboxylate, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of reducing the solubility of AAKG and the uniformity of product quality mixing Larger, complex process and other problems, to achieve the effect of reducing production costs, shortening production links, and improving quality control levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0036] [Implementation Case 1] Preparation of monoarginine ketoglutarate MAAKG

[0037] Add CaCl to 5 L of arginine fermentation broth 2 25g of powder, stirred to fully dissolve, let stand for 2 h, and then centrifuged in batches by a large-capacity centrifuge (8000 r / min, 10 min), and collected the filtrate to obtain 4.6 L. The content of L-arginine was determined to be 45.0 g / L, and the solution contained 1.19 mol of L-arginine. The α-ketoglutaric acid fermentation filtrate was pretreated in a similar manner, and the mol amount was calculated.

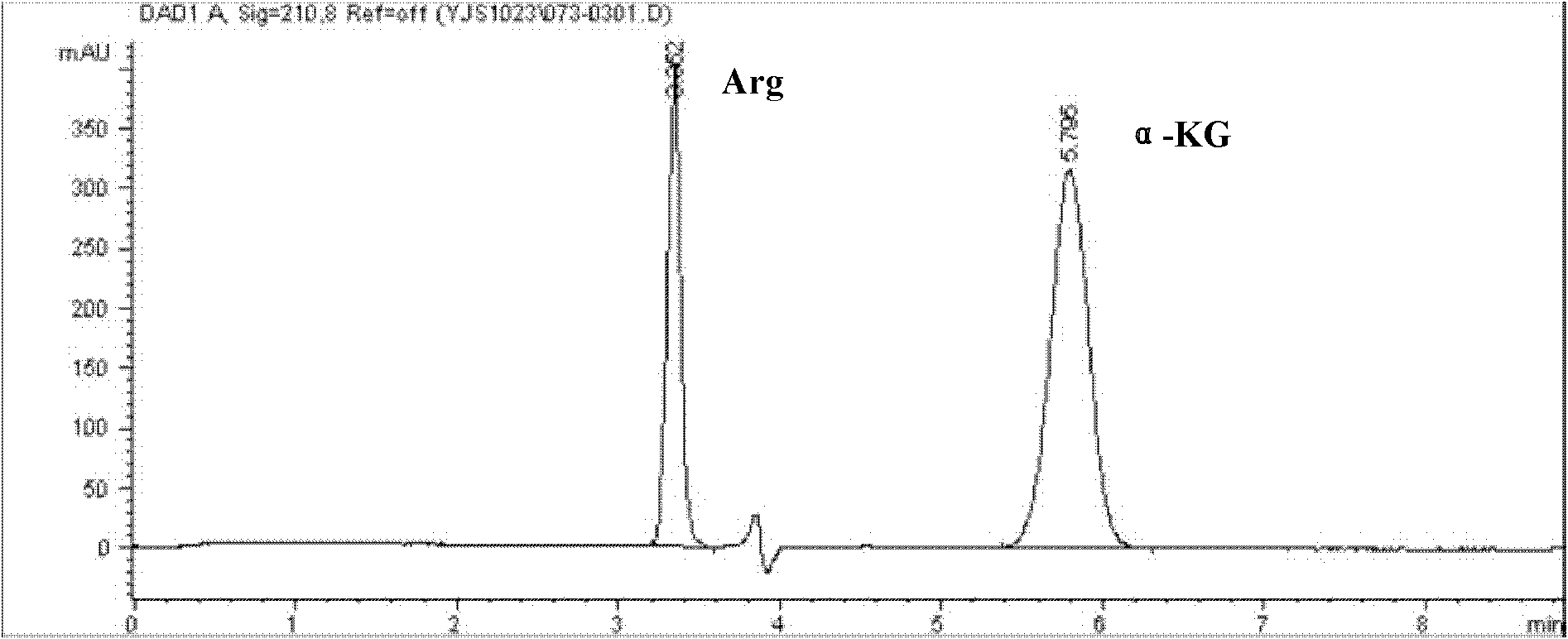

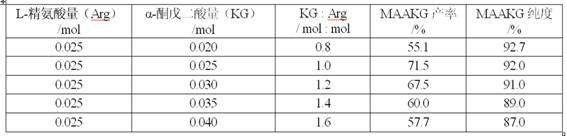

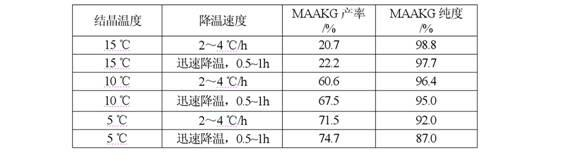

[0038] Calculated according to the mol ratio L-arginine:α-ketoglutarate=1:1, under the condition of stirring, slowly add the α-ketoglutarate fermentation filtrate to the L-arginine fermentation filtrate, so that It is completely mixed. The mixed solution was concentrated by a rotary evaporator with a water bath temperature of 65°C to obtain a concentrated solution of 1200 mL, which was 26.1% of the fermentation filtrate of L-argi...

Embodiment example 2

[0043] [Example 2] Preparation of double arginine ketoglutarate DAAKG

[0044] Add 25 mL of 1.0% chitosan hydrochloric acid (1.0%) solution to 5 L of arginine fermentation broth, stir and let stand for 1.0 h, vacuum filter, and collect the filtrate to obtain 4.2 L. The content of L-arginine was determined to be 52.0 g / L, and the solution contained 1.25 mol of L-arginine. Fermentation of α-ketoglutaric acid was carried out in the same way to obtain the fermentation filtrate.

[0045] Take the fermentation filtrate containing 91.6 g of α-ketoglutarate (add according to the molar ratio of L-arginine: α-ketoglutarate = 1 : 0.5), and slowly add it to the L-arginine fermentation broth while stirring to mix completely. The mixed liquid was concentrated by using a rotary evaporator, and the temperature of the water bath was 65 °C to obtain a concentrated liquid of 1680 mL, which was 40% of the fermentation filtrate of L-arginine and α-ketoglutarate before mixing. Put it in a refrig...

Embodiment example 3

[0050] [Implementation Case 3] AAKG Preparation Technology in Pilot Scale

[0051] L-Arginine Ferment Broth 5 M 3 , the content of arginine is 48 g / L. Add CaCl 2 25 kg of powder, stir to fully dissolve, let stand for 2 h, use plate and frame filter equipment (filter area is about 25.0 m 2 ) to filter and wash the filter residue. Collect 4350 L of clear filtrate.

[0052]The α-ketoglutarate used in the salification reaction with arginine also uses fermentation broth, and its pretreatment process is similar to that of L-arginine. The content of α-ketoglutarate in the clarified filtrate is 39.2 g / L.

[0053] Taking the production of MAAKG as an example, add according to the molar ratio of L-arginine: α-ketoglutarate = 1: 1, and add the α-ketoglutarate fermentation filtrate to the L-arginine filtrate, Stir evenly, and the mixed fermentation broth is 8.82 M in total 3 .

[0054] Two-effect vacuum concentration equipment was used to concentrate to 1500 L, and the volume of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com