Mafic-magnalium compound spinel brick and preparation method thereof

A magnesia-aluminum spinel and spinel brick technology, which is applied in the field of magnesia-iron-magnesium-aluminum composite spinel bricks and their preparation, can solve problems such as unsatisfactory performance and environmental pollution, and achieve stable product performance and alkali resistance. Good aggressiveness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

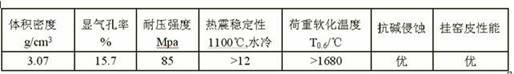

Embodiment 1

[0020] Embodiment 1: Magnesium-iron-magnesium-aluminum composite spinel bricks for cement kiln, expressed in weight percentage, raw materials are: 5-3mm high-iron magnesia accounts for 34%, and less than 2mm high-iron magnesia accounts for 27%, less than 0.088mm The high-iron magnesia accounts for 33%, and the magnesia-aluminum spinel less than 3mm accounts for 6%. In addition, 2-4% of the total weight of the above-mentioned raw materials is added as a binder. The density of the sulfurous acid pulp waste liquid is 1.2 g / cm 3 .

[0021] Among them, the weight composition of high iron magnesia is: MgO 85%, Fe 2 o 3 10%, other impurities 5%; the weight composition of magnesium aluminum spinel is: MgO 30%, Al 2 o 3 68%, other impurities 2%.

[0022] Preparation method: Mix the raw materials with a wet mill, shape them with a hydraulic press, put the shaped bricks into a drying kiln, dry them at 160°C for 8 hours to make the moisture content ≤0.5%, then heat them to 1660°C, a...

Embodiment 2

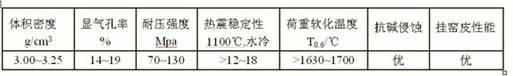

[0025] Embodiment 2: Magnesium-iron-magnesium-aluminum composite spinel bricks for cement kilns, expressed in weight percentage, raw materials are: 32% of high-iron magnesia of 5-3mm, 25% of high-iron magnesia of less than 2mm, and high-iron magnesia of less than 0.088mm 31% magnesia, 12% magnesia-aluminum spinel less than 3mm, additionally add sulfurous acid pulp waste liquid accounting for 3% of the total weight of the above raw materials, the density of sulfurous acid pulp waste liquid is 1.3g / cm 3 .

[0026] The weight composition of high iron magnesia is: MgO 90%, Fe 2 o 3 8%, other impurities 2%; the weight composition of magnesium aluminum spinel is: MgO 35%, Al 2 o 3 62%, other impurities 3%.

[0027] Preparation method: mix the raw materials with a wet mill, shape them with a friction press, put the shaped bricks into a drying kiln, dry them at 110°C for 24 hours, make the moisture content ≤0.5%, then heat them to 1700°C, and Burning under heat preservation for ...

Embodiment 3

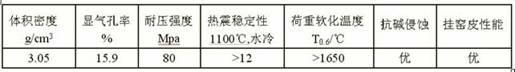

[0030] Embodiment 3: Magnesium iron-magnesium aluminum composite spinel bricks for cement kiln, expressed in weight percentage, raw materials are: 27% of high iron magnesia of 5~3mm, 20% of high iron magnesia less than 2mm, less than 0.088mm of high iron magnesia Magnesia 31%, 5~3mm magnesia-aluminum spinel 12%, 3 .

[0031] Among them, the weight composition of high iron magnesia is: MgO 80%, Fe 2 o 3 15%, other impurities 5%; the weight composition of magnesium aluminum spinel is: MgO 49%, Al 2 o 3 50%, other impurities 1%.

[0032] Preparation method: The raw materials are mixed by a wet mill, shaped by a friction press, put into a drying kiln, dried at 130°C for 12 hours, heated to 1680°C, and kept at this temperature for 12 hours to obtain the product The main components are: MgO76%, Al 2 o 3 15%, Fe 2 o 3 5%.

[0033] Its performance indicators are shown in Table 4 below:

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com