Crystallization apparatus of sulfur ammonium

A crystallization, ammonium sulfate technology, applied in ammonia compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of occupying the reactor space, fast local neutralization reaction speed, reducing the effective height of the pre-thickener elutriation section, etc. Achieve the effect of optimizing the nucleation speed and number, improving the flow and mixing effect, and improving the material and liquid circulation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

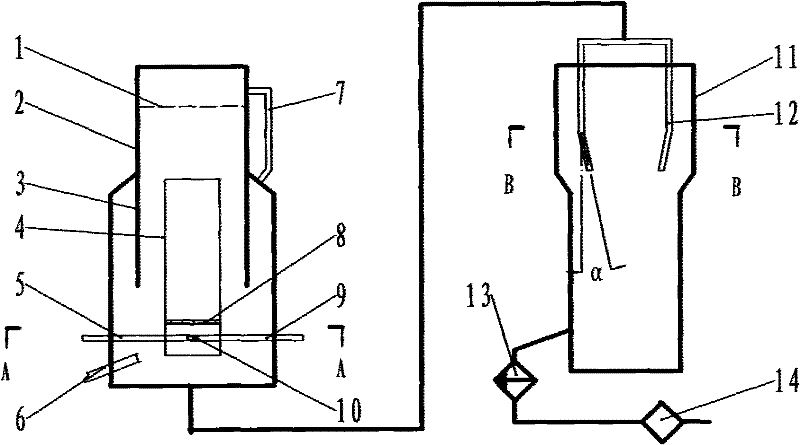

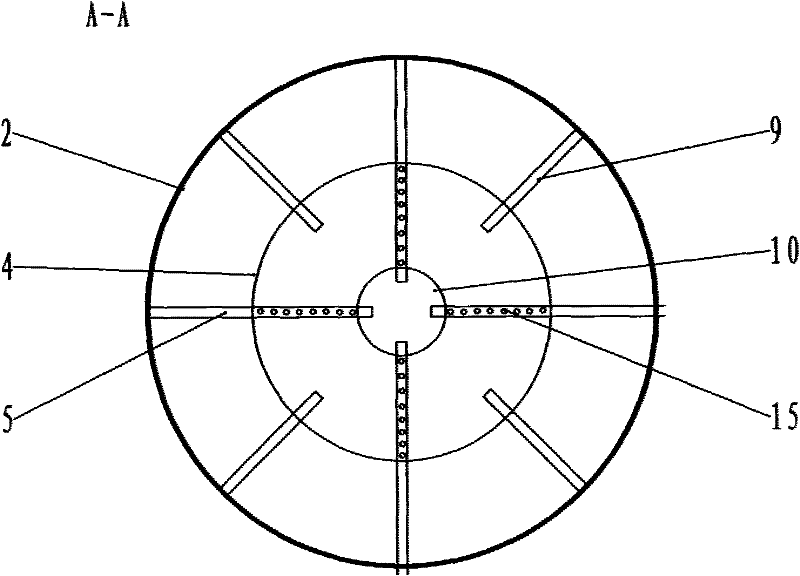

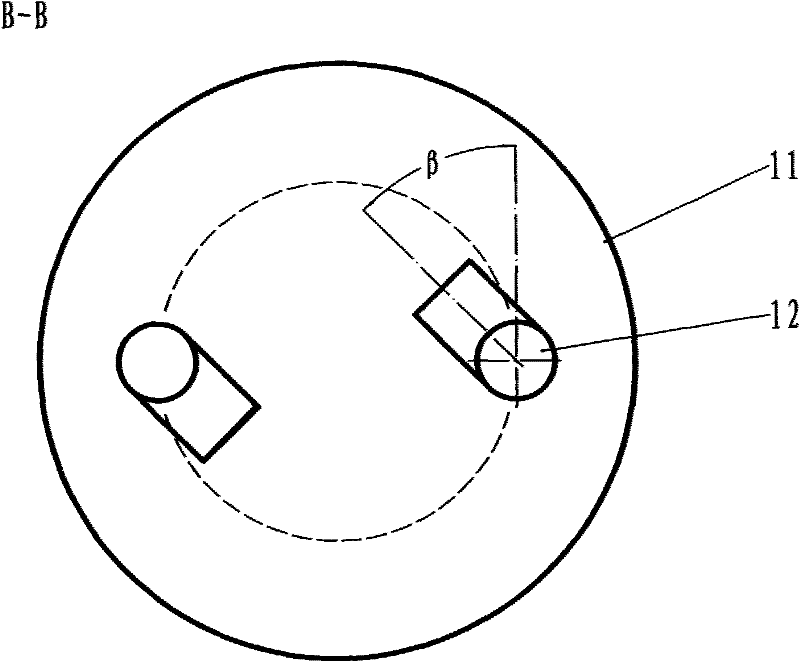

[0015] A device for a kind of ammonium sulfur crystals described in the present invention figure 1 It mainly includes crystalline reactors 2. Premature device 11, centrifugal machine 13, and dryer 14, and each device is connected by pipelines.The crystalline reactor is the form of upper and lower diameters, and the upper diameter is less than the lower diameter.To avoid an ammonium sulfur crystal, scars are attached and scars on the wall, the inner wall of the crystalline reactor is coated with polytrafluoroethylene coating.Crystal reactor has a circular folding plate 3. Diveivation cylinder 4. Gas balance tube 7, ammonia gas distribution device 9, shaft stirring paddle 8, acid group distributor 5, and distributer connector 10.Folding board 3 extends vertically from the upper wall to the middle of the crystalline reactor; the gas balance tube is installed outside the crystalline reactor.On the lower end of the upper part of the folding board.The derivative tube is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com