Proton exchange membrane as well as preparation method and application thereof

A technology of proton exchange membrane and exchange resin, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of mechanical property degradation, easy rupture, membrane mechanical performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

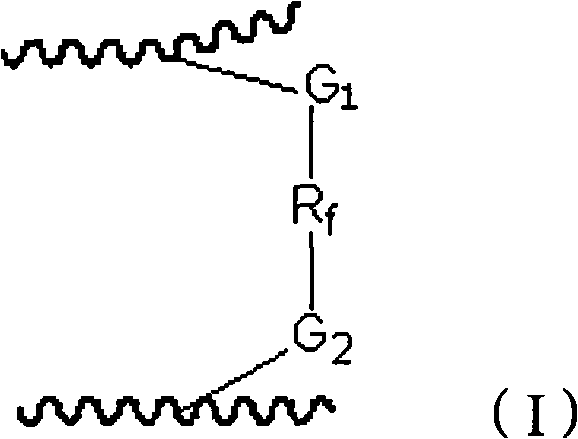

[0124] This example is used to illustrate the proton exchange membrane provided by the present invention and its preparation method. Convert the repeating unit to

[0125] Perfluorinated ion exchange resin with EW=1000 and cerous carbonate (weight ratio to resin: 1:100), Zr(HPO with a particle size of 0.005 μm) 4 ) 2 (The weight ratio with the resin is 3:100) to prepare a 5% by weight propanol aqueous solution. Then a DMF solution of perfluoromalonyl peroxide with a concentration of 5% by weight was prepared.

[0126] Take a substrate with a thickness of 30 μm and a porosity of 70% (wherein h=0, i=2, A=OH) carry out the polytetrafluoroethylene microporous membrane of surface modification, be placed in above-mentioned solution and soak for about 1 hour, then the soaked membrane is dried on the heating plate, meanwhile Roll the film with a rubber roller. Above-mentioned solution is poured in the polytetrafluoroethylene casting mold that places horizontally, through 80 ℃ ...

Embodiment 2

[0128] This example is used to illustrate the proton exchange membrane provided by the present invention and its preparation method.

[0129] Convert the repeating unit to Perfluorinated ion exchange resin with EW=800 and SiO with a particle size of 0.03 μm 2 (The weight ratio of the resin to the resin is 5:100), the surface is covered with (where h=0, i=4, A=ONa) modified polyperfluoroethylene propylene fibers (diameter 0.05 μm, length 5 μm, weight ratio to resin 1:40) were mixed and extruded to obtain a film with a thickness of 30 μm.

[0130] take (where h=0, i=4, A=ONa) the porous hexafluoropropylene membrane with a thickness of 12 μm and the above-mentioned 30 μm membrane are heat-pressed together under vacuum at 260° C., and then heated in a vacuum oven at 150° C. Soak in NH for 1 hour 4 Cl in DMF for 5 hours. The soaked membrane was then placed in triethylamine at 200 °C for 2 hours to obtain a cross-linked membrane. The membrane was sequentially treated with K...

Embodiment 3

[0135] This example is used to illustrate the proton exchange membrane provided by the present invention and its preparation method.

[0136] Convert the repeating unit to

[0137] Perfluorinated ion exchange resin with EW=1100, lanthanum acetate (weight ratio to resin is 0.001:100) and Ce(HPO 4 ) 2 (the weight ratio to the resin is 0.001:100) to prepare a solution with a resin content of 3% by weight (the solvent is water and ethanol at a weight ratio of 1:1). surface will be (wherein, l=1, D=H) the grafted porous polytetrafluoroethylene-hexafluoropropylene film is immersed in the above solution, and after 30 minutes, the film is taken out and dried, and then the film is cross-linked by 50KGy radiation to obtain a thickness of 10 μm The cross-linked structure is (I) kind of ionic membrane (4# membrane).

[0138] Convert the repeating unit to Perfluorinated ion-exchange resin with EW=940, Ce(III)-DMSO complex (weight ratio to resin is 0.1:100) and H 3 PW 12 o 40 (T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com