Method and device for removing low-concentration sulfur dioxide in flue gas

A sulfur dioxide, low-concentration technology, applied to chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of waste of sulfur resources, easy scaling, and increased operating costs, to increase the contact area and facilitate installation and maintenance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

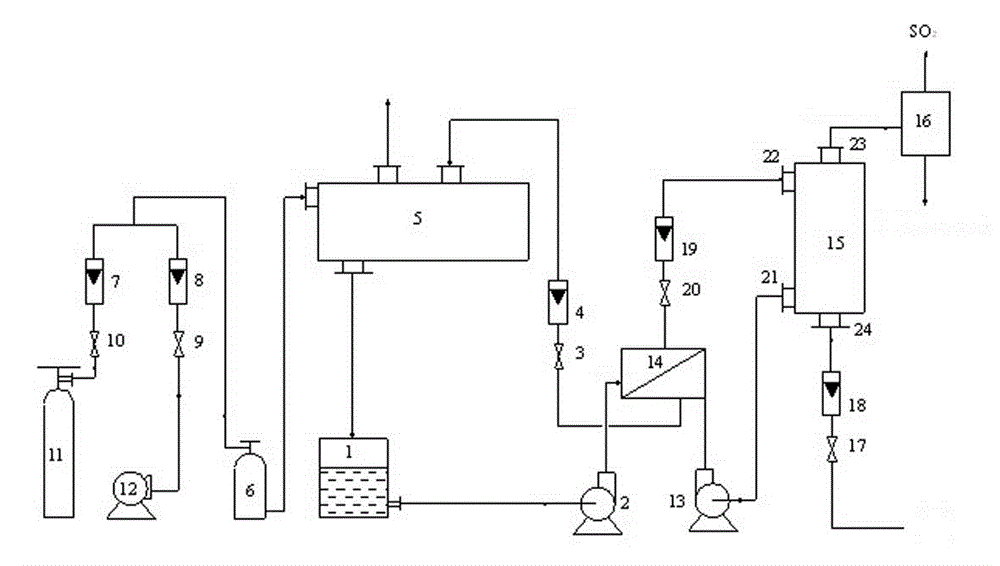

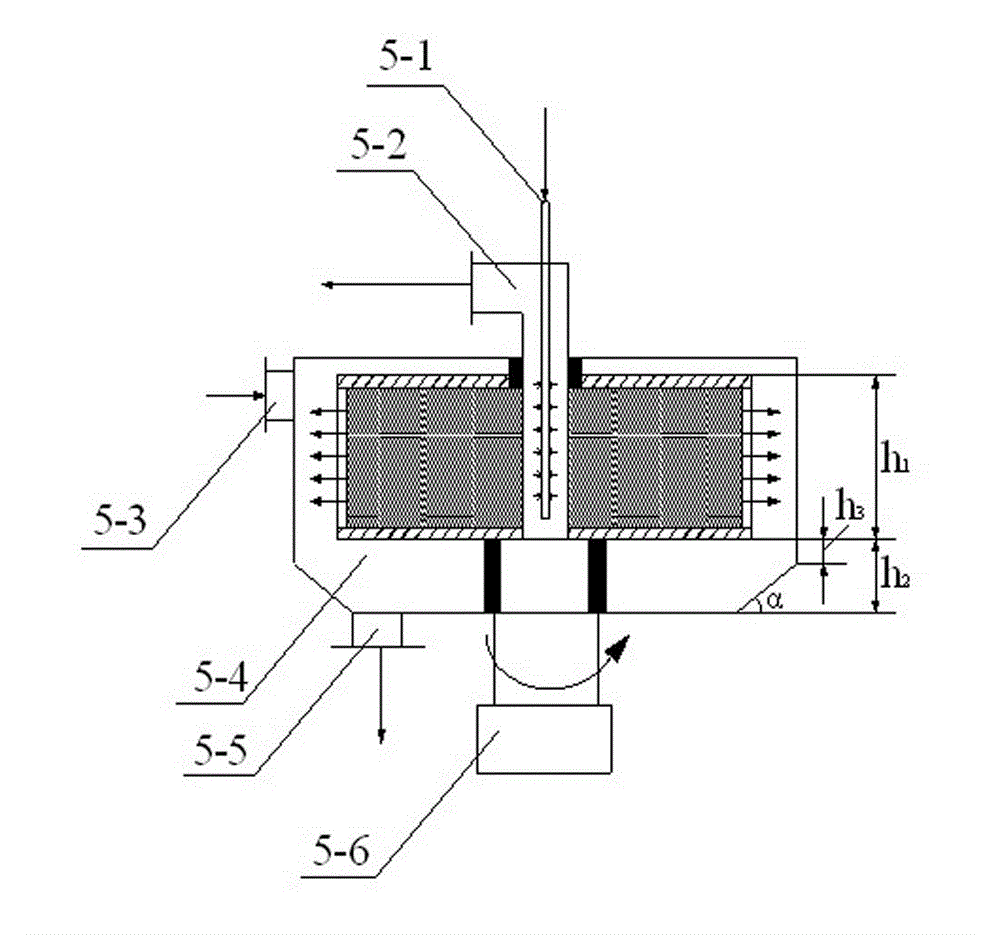

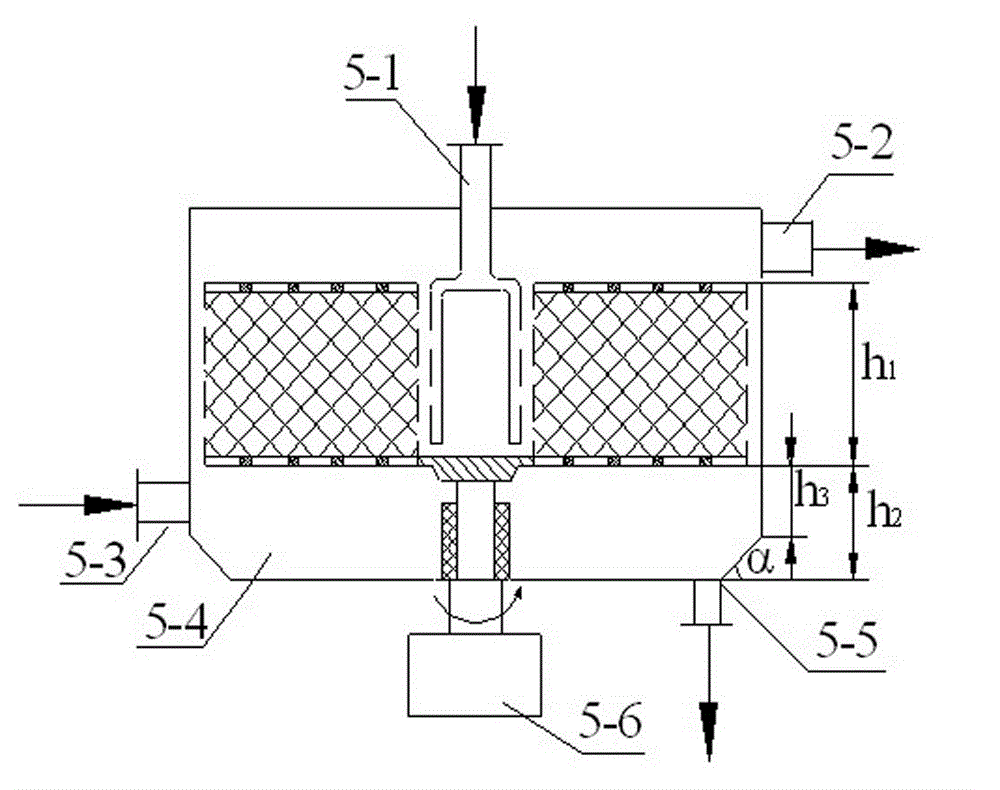

Embodiment 1

[0037] Adjust the rotating speed of the rotary packed bed 5 to be 500r / min, the absorption solution with a citric acid concentration of 0.1mol / L and a pH value of 6 is added to the rotary packed bed 5 through the liquid inlet 5.1 of the rotary packed bed, and the mass concentration of sulfur dioxide is 2000mg / m 3 The simulated flue gas enters the rotating packed bed 5 through the rotating packed bed gas inlet 5.3, the absorption temperature is 40°C, and the gas flow rate is 60m 3 / h, adjust the liquid-gas ratio to 7 (L / m 3 ), the gas phase and the liquid phase contact and react rapidly in the rotating packed bed 5, the purified gas is discharged from the rotating packed bed gas outlet 5.2, and the citrate solution dissolved in sulfur dioxide is discharged from the rotating packed bed liquid outlet 5.5, and is desorbed by the desorption system After returning to the absorption system for recycling, the gas-liquid ratio of the desorption operation is 900m 3 / m 3 , the desorpti...

Embodiment 2

[0039] Adjust the rotational speed of the rotary packed bed 5 to be 1000r / min, add the absorption solution with a concentration of citric acid of 1.5mol / L and a pH value of 2 to the rotary packed bed 5 through the liquid inlet 5.1 of the rotary packed bed, and the mass concentration of sulfur dioxide is 8500g / m 3 The simulated flue gas enters the rotary packed bed 5 through the rotary packed bed gas inlet 5.3, the absorption temperature is 30°C, and the gas flow rate is adjusted to 30m 3 / h, adjust the liquid-gas ratio to 4 (L / m 3 ), the gas phase and the liquid phase contact and react rapidly in the rotating packed bed 5 . The purified gas is discharged from the gas outlet 5.2 of the rotating packed bed, and the citrate solution dissolved in sulfur dioxide is discharged from the liquid outlet 5.5 of the rotating packed bed. After being desorbed by the desorption system, it is returned to the absorption system for recycling. The gas-liquid ratio of the desorption operation is ...

Embodiment 3

[0041] Adjust the rotational speed of the rotary packed bed 5 to be 3000r / min, add the absorption solution with a citric acid concentration of 1.0mol / L and a pH value of 4.5 to the rotary packed bed 5 through the liquid inlet 5.1 of the rotary packed bed, and the mass concentration of sulfur dioxide is 5000g / m 3 The simulated flue gas enters the rotary packed bed 5 through the rotary packed bed gas inlet 5.3, the absorption temperature is 60°C, and the gas flow rate is adjusted to 40m 3 / h to adjust the liquid-gas ratio to 3 (L / m 3 ), the gas phase and the liquid phase contact and react rapidly in the rotating packed bed 5 . The purified gas is discharged from the gas outlet 5.2 of the rotating packed bed, and the citrate solution dissolved in sulfur dioxide is discharged from the liquid outlet 5.5 of the rotating packed bed. After being desorbed by the desorption system, it is returned to the absorption system for recycling. The gas-liquid ratio of the desorption operation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com