Arc extinguish chambers of high voltage alternating current SF6 pot-type breaker

A high-voltage AC and interrupter technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., to achieve the effects of short cycle times, improved safety and reliability, and strong capacitive current breaking capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

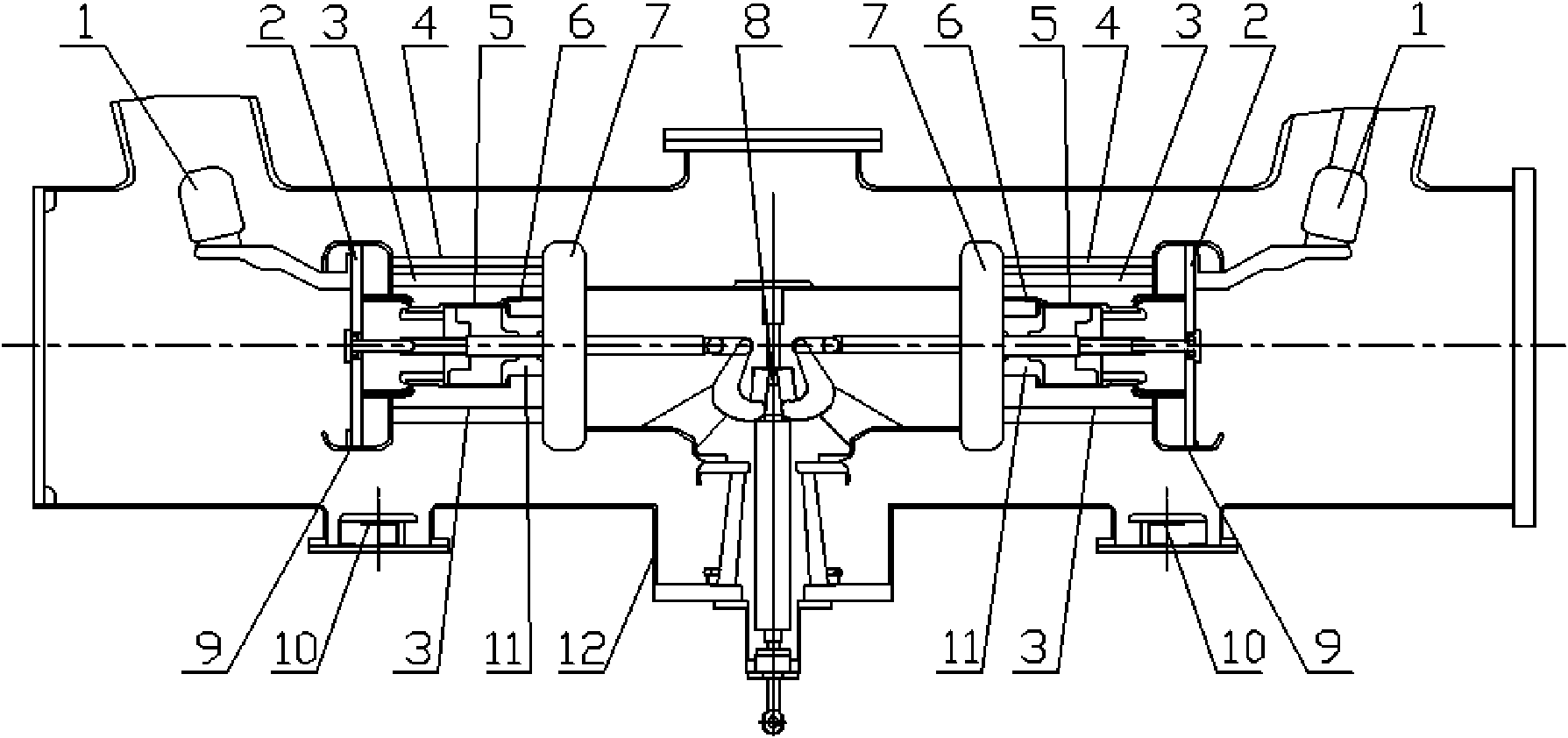

[0032] Such as figure 1As shown, the arc extinguishing chamber of the high-voltage AC double-break SF6 tank circuit breaker is composed of the shell 12 for assembling the arc extinguishing chamber, the plum contact system 1, the static contact system 2, the capacitor assembly unit 4, and the cylinder system 5 , mechanical transmission system 8, ion capture system 10, pneumatic piston assembly unit 11, intermediate contact assembly unit 6, insulating support rod 3, moving end large shield 7, static end large shield 9, etc. The arc extinguishing chamber is a double-fracture structure, symmetrically distributed on both sides with the mechanical transmission system as the center, in which the mechanical transmission system 8 moves in the vertical direction, and the vertical movement is converted into a horizontal movement through the middle crank arm and connecting rod part of the mechanical transmission system 8, driving the extinguishing chamber. The two cylinder systems 5 in th...

Embodiment 2

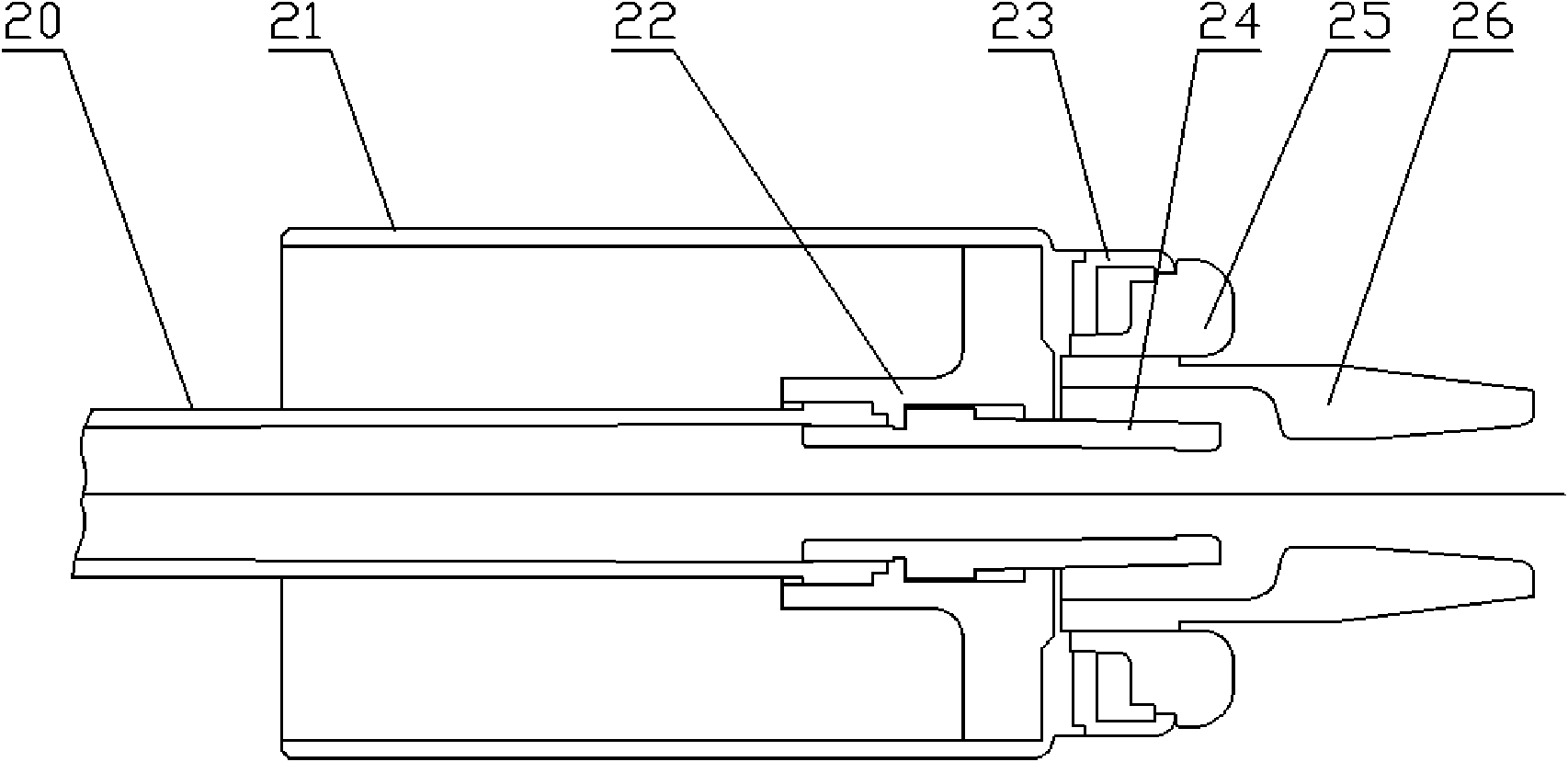

[0037] Such as figure 2 As shown, the arc extinguishing chamber pressure cylinder system 5 is mainly composed of a piston rod 20, a pressure cylinder 21, a cylinder seat 22, a moving main contact 23, a moving arc contact 24, a nozzle seat 25, a nozzle 26 and the like. The piston rod 20 and the cylinder seat 22 are connected by threads, and after being loaded into the cylinder 21, the moving main contact 23 and the nozzle seat 25 are connected to the cylinder seat by screws and fixed on the cylinder, and the moving arc contact 24 is fixed on the piston by threads. On the rod 20, the spout 26 is fixed on the spout seat 25 by threads.

[0038] Such as figure 2 As shown, there are two processing methods for the compressed air cylinder, one is to use a formed aluminum tube for processing, and the other is to use a new technology for hot extrusion, and the second method is to use a bar material and carry out hot extrusion through a vacuum extrusion welding chamber Press forming,...

Embodiment 3

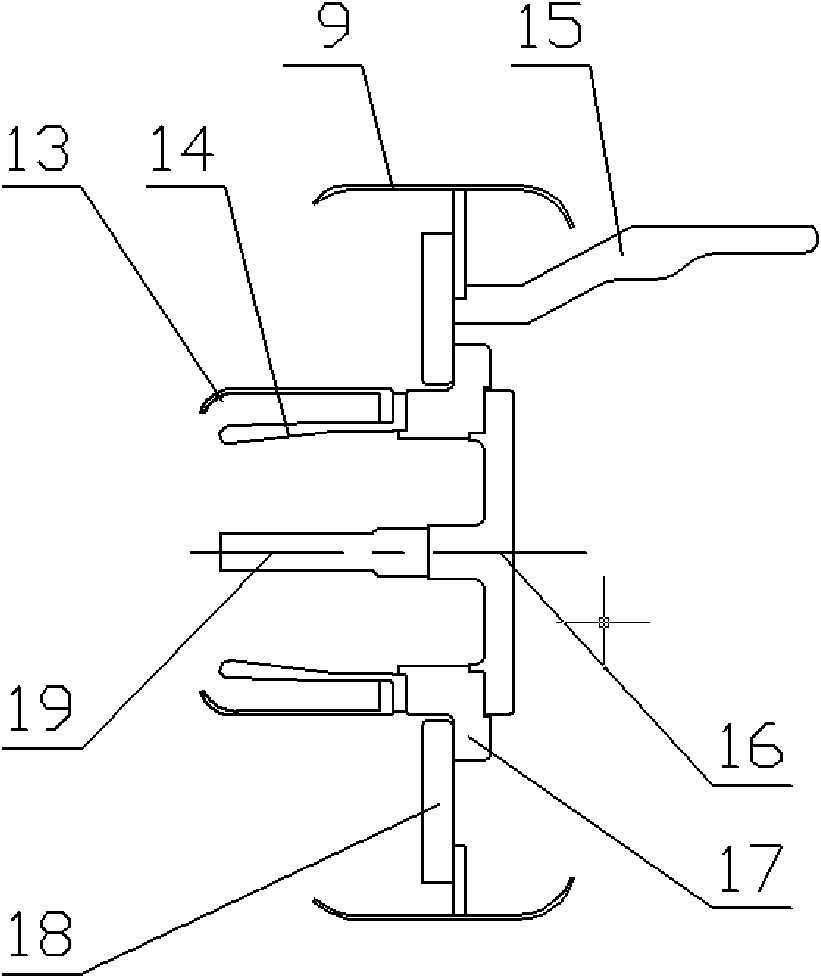

[0040] Such as image 3 As shown, the static contact system 2 of the circuit breaker arc extinguishing chamber is mainly composed of a shield cover 13, a static main contact 14, a conductive rod 15, a static arc contact seat 16, a connecting flange 17, a flange 18, and a static arc contact 19 , Static end large shielding cover 9 etc. composition. The flange 18 is connected to the connecting flange 17 by screws, the shield cover 13 and the static main contact 14 are connected to the connecting flange 17 by screws and positioning snaps, the static arc contact 19 is connected to the static arc contact seat 16 by threads, Then it is fixed on the connecting flange 17 by screws, and the conductive plate 15 and the large shielding cover 9 at the static end are connected to the flange 18 by screws.

[0041] Such as image 3 As shown, the shielding cover 13 is welded by two parts, and the whole spinning shielding is welded with the flange, the processing cycle is short, the cost is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com