Electronic transformer

An electronic transformer and iron core technology, applied in transformers, fixed transformers, inductors, etc., can solve the problems of unapproved and market access, potential safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

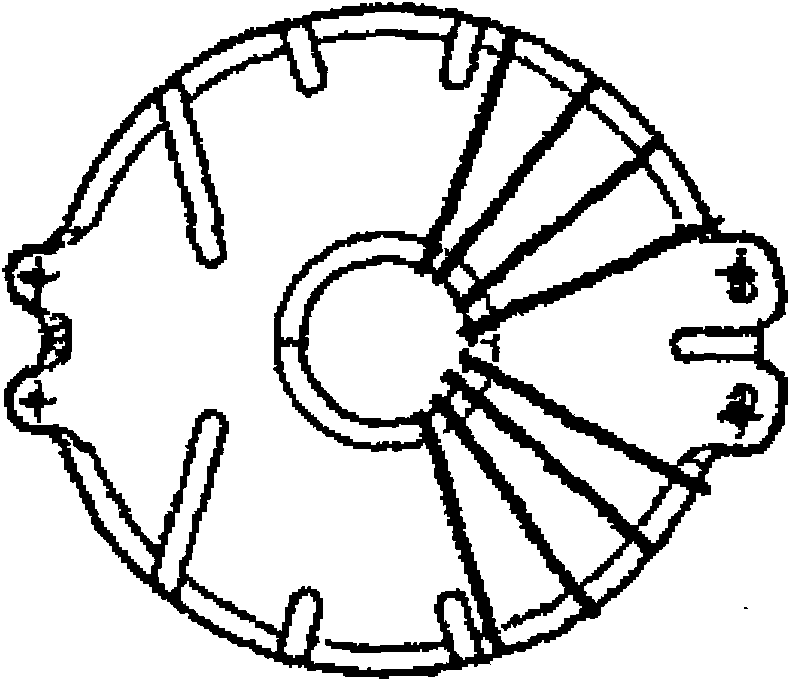

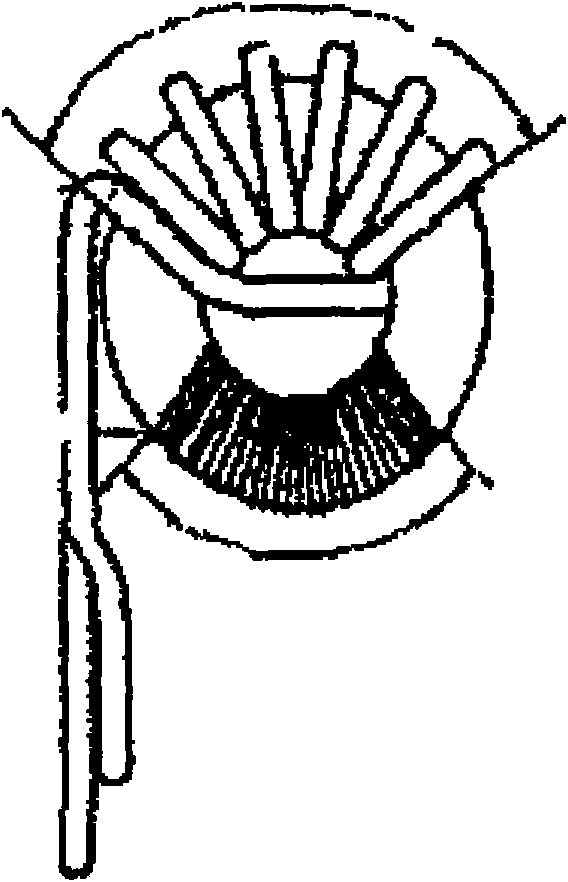

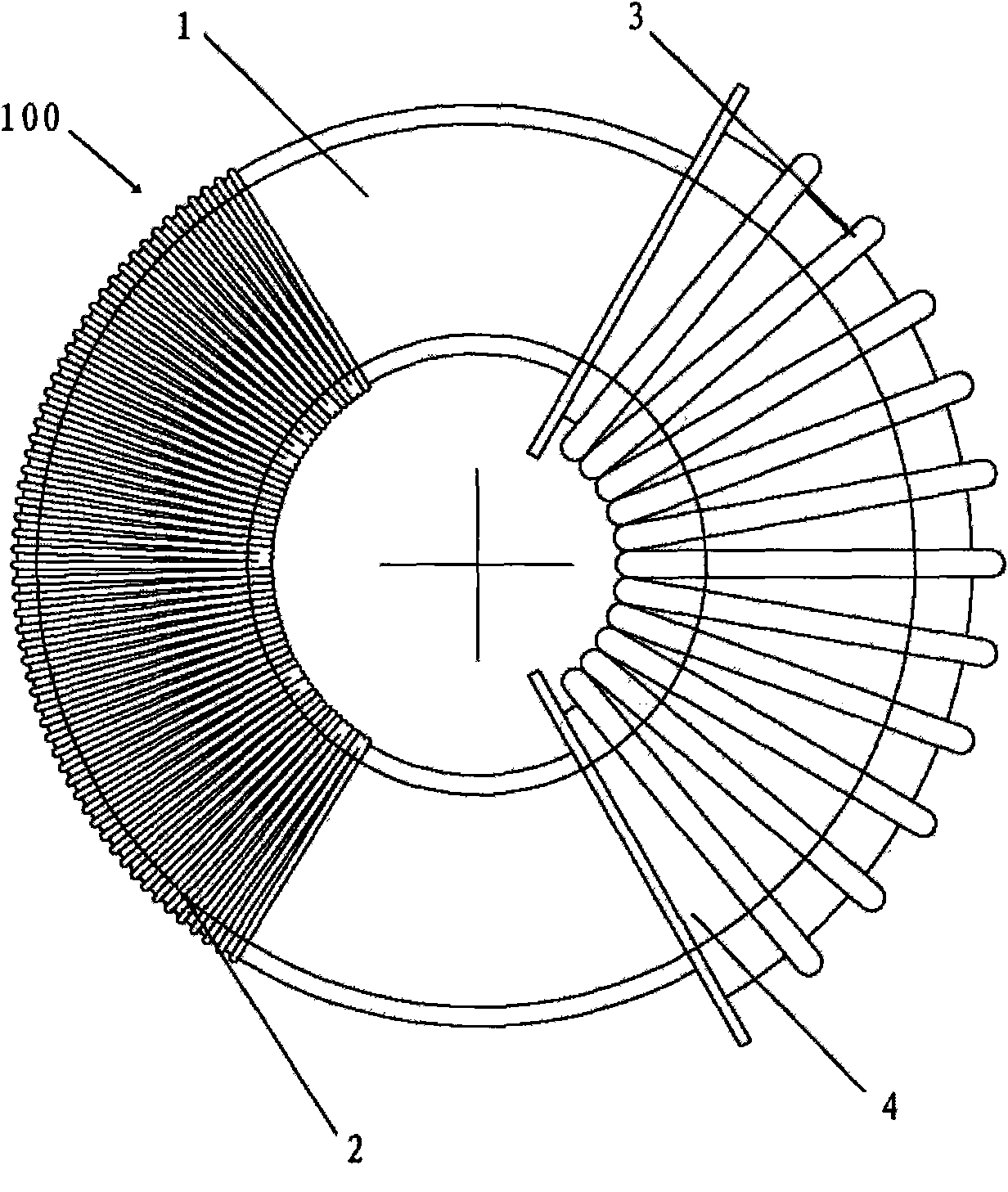

[0028] image 3 and Figure 4 are a plan view and a perspective view showing an electronic transformer according to an exemplary embodiment of the present invention, respectively. As shown, the electronic transformer is generally designated by the reference numeral 100 .

[0029] The electronic transformer 100 includes an iron core 1 , a primary coil (primary side) 2 and a secondary coil (secondary side) 3 . In this embodiment, the iron core 1 is an annular iron core, and preferably, the iron core 1 is a ferrite iron core, and has been properly coated with insulating varnish. The primary coil 2 and the secondary coil 3 are respectively wound on the iron core 1 , in other words, conductive wires are wound on the iron core to form coils. The conductive wire may comprise a single wire type or a braided (ie Litz wire) type, and is preferably en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com