Annular light source test platform

A platform and light source technology, applied in the field of electromechanical, can solve problems such as damage to the reticle, and achieve the effect of improving the quality and improving the quality of the reticle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention, the features and functions of the preferred embodiments of the present invention will be described in detail as follows in order to facilitate a complete understanding.

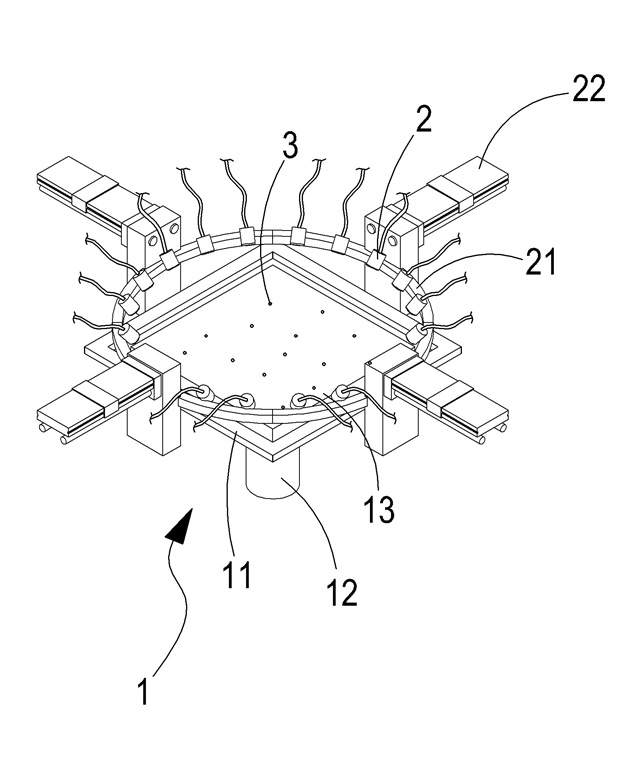

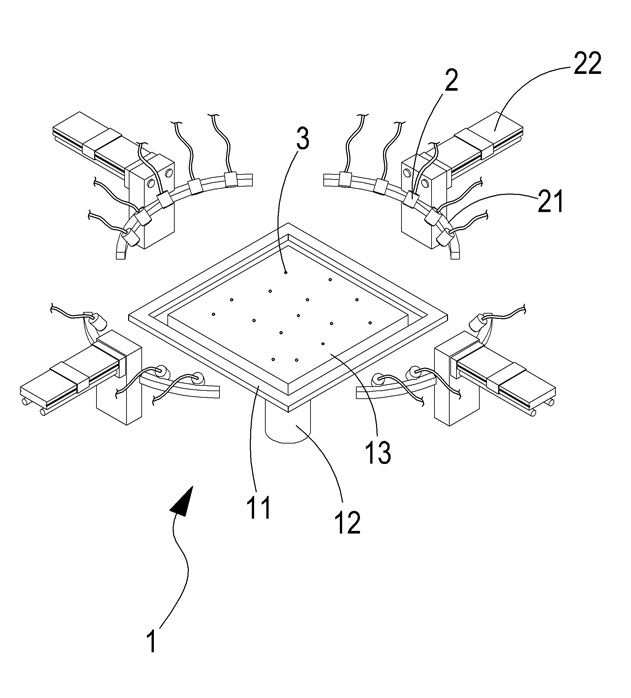

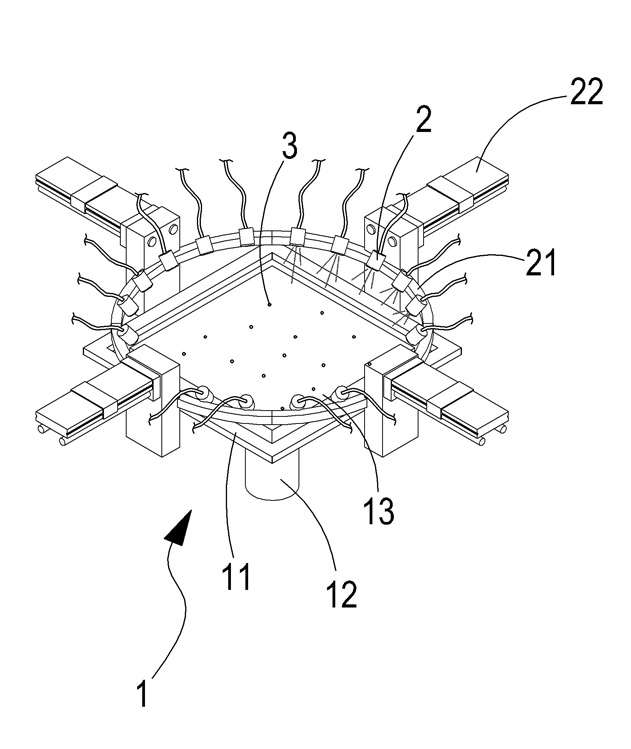

[0025] as attached figure 1 with attached figure 2 As shown, it is a perspective view and a three-dimensional exploded view of a preferred embodiment of the present invention, and it can be clearly seen that the present invention includes:

[0026] The supporting frame 1, the supporting frame 1 includes a supporting platform 11 for fixedly placing a preset photomask 13 and a support 12 supporting the supporting platform 11, the supporting frame 12 can freely rotate or move the supporting platform up and down. Set platform 11, between this bearing platform 11 and this support 12 is provided with an adjusting member that can make this bearing platform 11 rotate freely and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com