High-power light-emitting diode (LED) lamp cap with epoxy resin heat conduction pipe added with carbon nano tube material

A technology of LED lamp holders and carbon nanotubes, which is applied to cooling/heating devices of lighting devices, lighting and heating equipment, and components of lighting devices, etc., which can solve the problem of insufficient effective heat dissipation area and the heat conduction and heat dissipation fins that cannot heat dissipation substrates. Fins, lack of heat dissipation substrate heat conduction heat dissipation fins and other issues, to achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

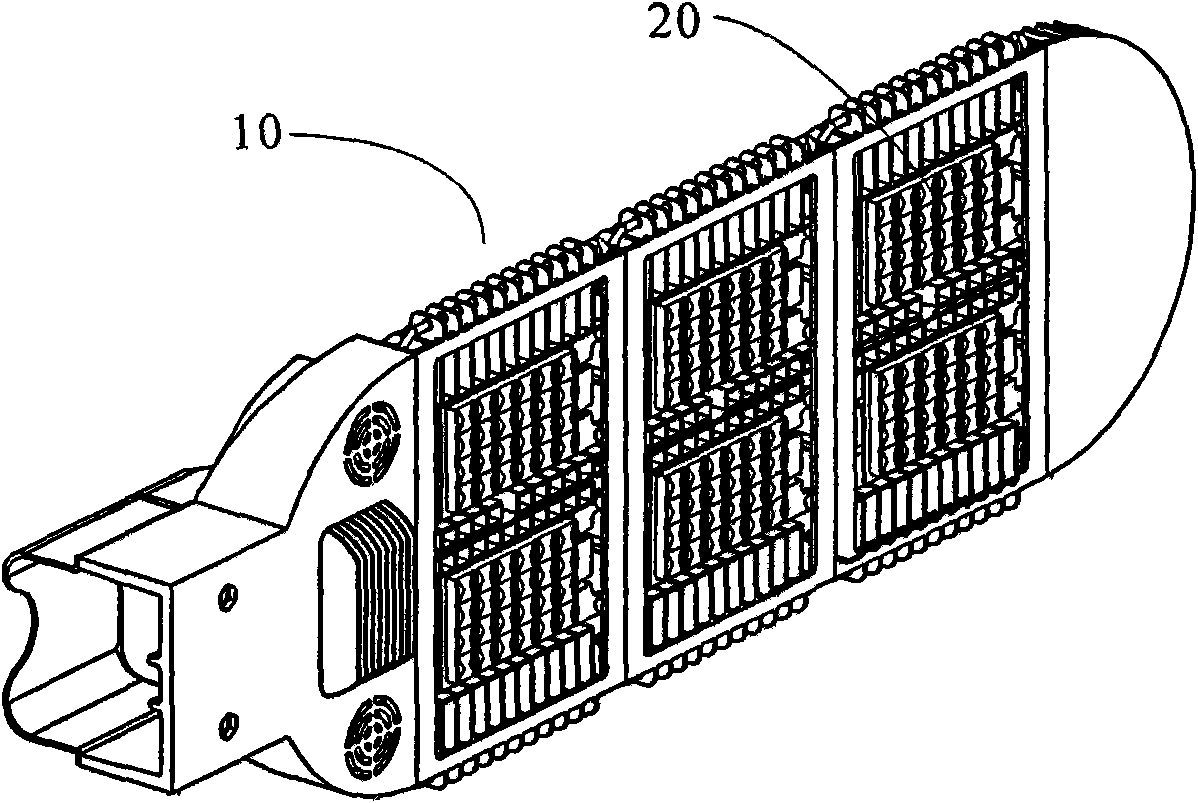

[0042] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

[0043] Carbon Nanometer Tube, abbreviated as CNT, is a seamless nanoscale tubular crystal formed by curling graphite layers, including single-walled carbon nanotubes abbreviated as SWCNT and multi-walled carbon nanotubes abbreviated as MWCNT Carbon Nanotube Multi-Walled Carbon Nanometer Tube. SWCNT can be regarded as rolled from graphite sheets, and MWCNT is composed of many single-walled shells. The diameter of SWCNT is generally 1 ~ 6nm, the smallest diameter is about 0.5nm, and C 36 The molecular diameters are similar, but SWCNTs are particularly unstable when the diameter is greater than 6nm, and the SWNT tube will collapse, and the length can reach hundreds of nanometers to several microns. Because the minimum diameter of SWCNT is similar to that of fullerene molecules, it is also called bucky tube or fuller tube. The layer spacing of MWCNT is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com