Emulsifier for high-iron emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and emulsifier, applied in building components, building insulation materials, construction and other directions, can solve the problems of slow cooling, demulsification of emulsified asphalt, poor thermal stability of emulsified asphalt, etc., and achieves simple production process and high social efficiency. Economic benefits and the effect of extending the construction time limit of high-speed rail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be described in detail below in conjunction with the examples.

[0029] 1. Compounding of emulsifier

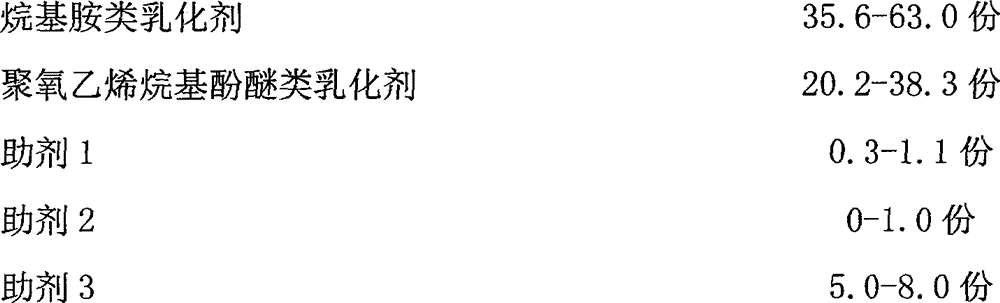

[0030] (1) Add 58.5kg tallow propylene diamine and 32.9kg octylphenol polyoxyethylene ether-10 (OP-10) successively in the reactor, open the stirrer of the reactor, the rotating speed is 60rads / min, then slowly heat to 100°C, constant temperature stirring for 60min;

[0031] (2) Cool the above materials to below 60°C, add 0.7kg of acetic acid and 1.0kg of calcium chloride, and continue stirring for 30min until completely dissolved;

[0032] (3) Cool the mixture obtained in (2) to room temperature, add 6.9 kg of ethanol, and stir until the materials are completely mixed to obtain 100 kg of emulsifier finished product.

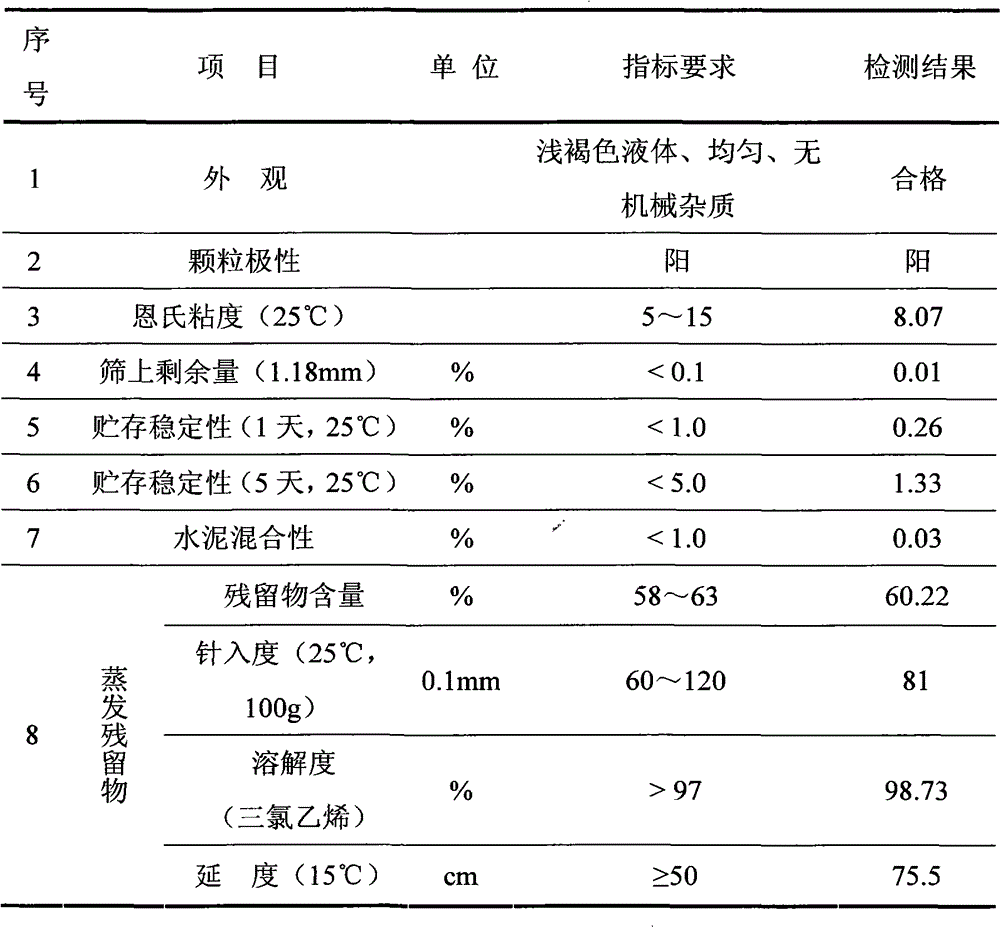

[0033] 2. Preparation of emulsified asphalt

[0034] Add 380kg of warm water at 70°C to the reaction kettle, then add 20kg of the reconstituted emulsifier into the warm wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com