Epoxy resin composition and adhesive sheet and substrate made by same

A technology of epoxy resin and composition, which is applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of film/substrate processability limitation, difficult machining, plate hardening, etc., and achieve the purpose of increasing drilling processability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

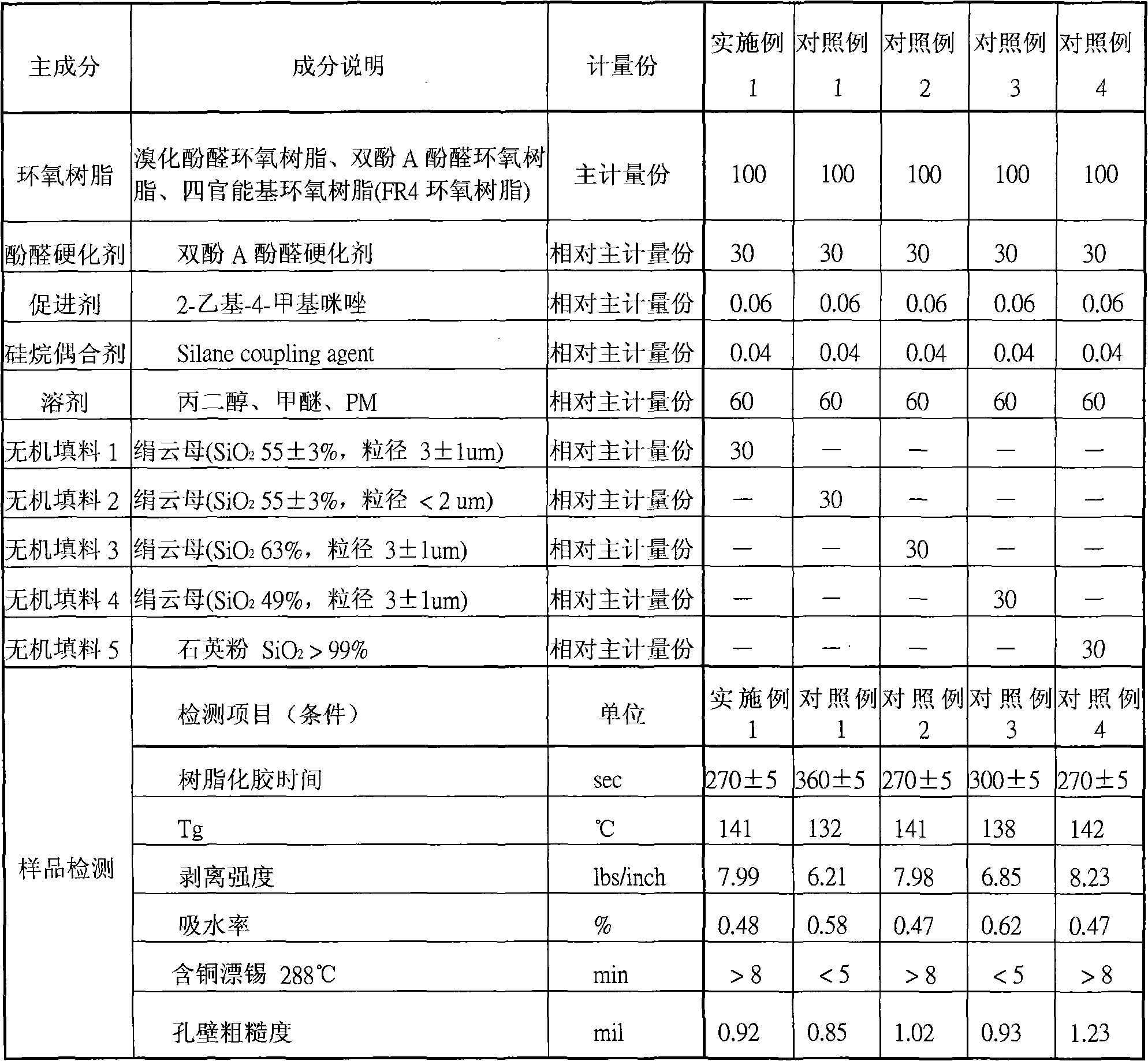

Embodiment 1

[0024] Embodiment 1 is the most preferred embodiment of the present invention, and in the composition of embodiment 1, the silica weight in this sericite powder composition is 55 ± 3%, and the particle diameter of this sericite powder is 3 ± 3%. 1um, from the data in Table 1, the resin glue time, peel strength and water absorption of the copper-clad substrate can meet the specifications of the substrate; and the glass transition temperature (Tg) is 141 ° C, indicating that its reactivity is also good; And it can be known that the film / copper-clad substrate manufactured after the glass fiber cloth impregnation operation through the epoxy resin composition glue proposed by the present invention has higher heat resistance, so the time required for the explosion board is longer and meets At the same time, the drilling roughness of the substrate can be reduced by up to 0.9mil, so the addition of low-hardness sericite powder (Mohs hardness 2 to 3) can reduce the interlayer peeling wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com